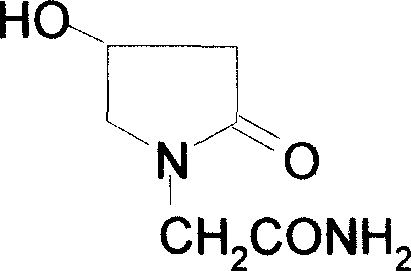

Method of preparing 4-hydroxy pyrrolidone-2-acetylamine

A technology of hydroxypyrrolidone and hydroxybutanone aminoacetamide, which is applied in the field of preparing 4-hydroxypyrrolidone-2-acetamide, can solve the problems that the purity cannot be fully used in medicine, cannot meet industrial scale production, and the product components are complex, etc. The effect of cheap raw materials, low cost, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in more detail with examples below, but it cannot be considered that the present invention is limited to this example.

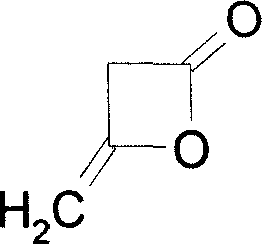

[0019] 1. Preparation of chloroacetoacetyl chloride

[0020] 500 ml of dichloromethane and 86 g of diketene (1.0 mol, purity 98%) were added to the reactor. The mixture was cooled to -10~-20°C while stirring, and 71 g (1.0 mol) of chlorine gas was introduced to react for 2 hours. Chloroacetoacetyl chloride was obtained by gas chromatography analysis.

[0021] 2. Preparation of chloroacetoacetamidoacetamide

[0022] Naturally warm up the chloroacetoacetyl chloride solution synthesized above to -10~0°C, add glycinamide hydrochloride 112g (1.0mol, purity 98.5%) in batches to this mixed solution while stirring, and keep warm for 2 Hour. Dichloromethane was recovered by distillation under reduced pressure, and the distillation residue was washed with ethanol to obtain 177.6 g (yield 90.8%) of the target product, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com