A kind of production method of methyl acetoacetate

A technology of methyl acetoacetate and its production method, which is applied in the preparation of ketene/polyketene, organic chemistry, etc., can solve the problems of lack of methyl acetoacetate, slow reaction speed, and many impurities in crude ester, and achieve technological Process safety, mild reaction conditions, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add methanol 1280Kg (40Kmol) in the 5000L reactor, catalyzer is 3 kilograms of triethylenediamine and sodium acetate 1.5 kilograms, stirs, and normal temperature is the starting temperature and begins to drop content and is 3000 kilograms (33.25Kmol) of thick diketene ketone of 93.1%, temperature Slowly rise to 115°C. The temperature range from the initial temperature to the final dropwise addition of diketene can be 20-110°C. After the dropping, continue to keep warm for 2-5 hours to complete the reaction.

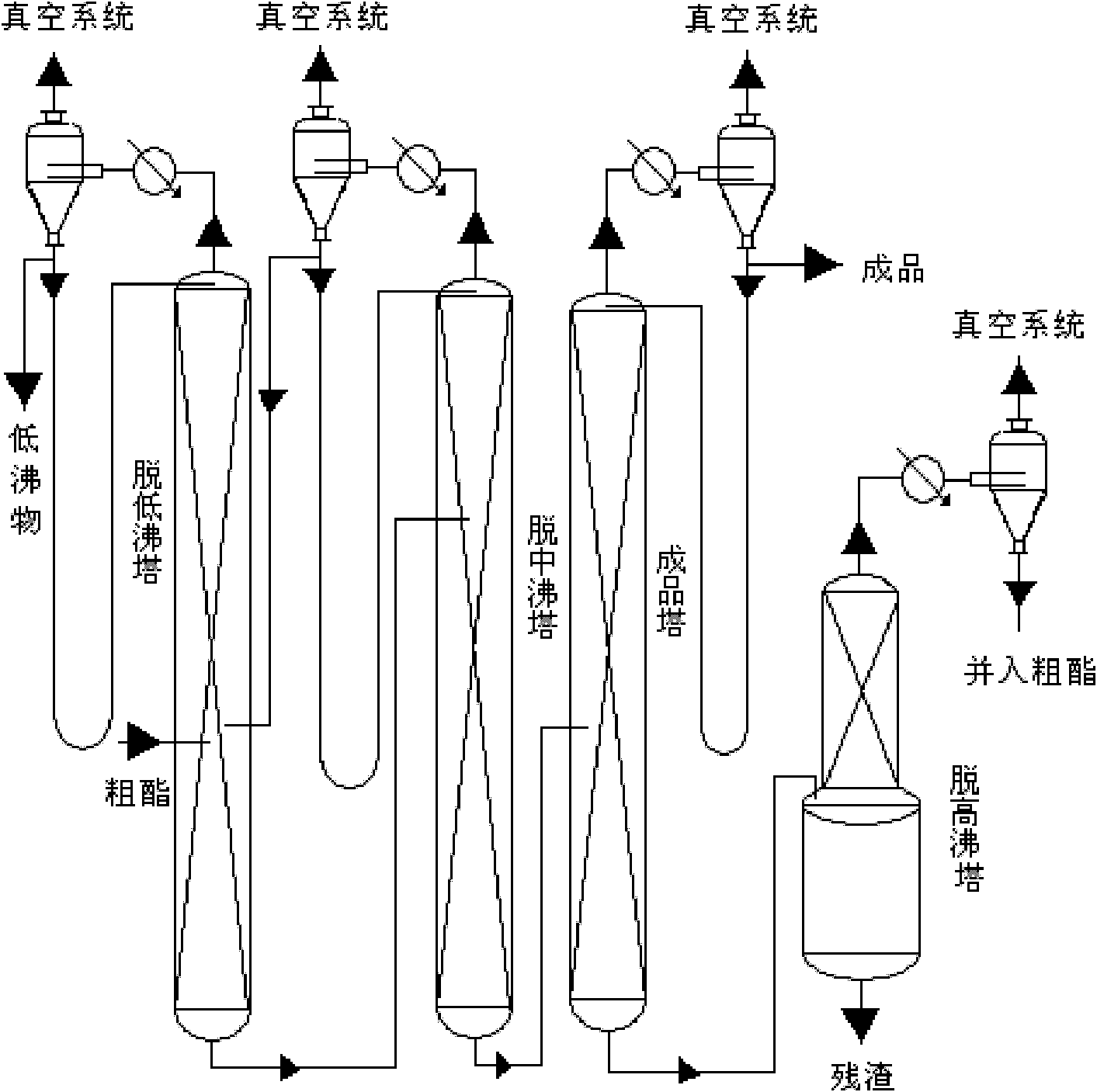

[0034] The reaction product enters the low boiling tower from the middle part of the low boiling tower, and removes methanol, acetone, methyl acetate and other low boiling point substances by continuous rectification under negative pressure at a vacuum degree of 0.08-0.09Mpa and a temperature of 70-100°C ; The material in the low boiling tower continuously enters the middle part of the medium boiling tower, and the vacuum degree is greater than 0.095Mpa and the temp...

Embodiment 2

[0036] Add methanol 1170Kg (37Kmol) in 5000L reactor, catalyst adopts 120 kilograms of triethylamines, thick diketene content is 91.3%, all the other are the same as embodiment 1, obtain 3597 kilograms of methyl acetoacetate products, product content is 99.74%, yield The rate is 95.1%.

Embodiment 3

[0038] Catalyst adopts 35 kilograms of trimethylamines, 4 kilograms of sodium methoxides, and normal temperature is that initial temperature begins dropwise content to be 2780 kilograms (30.77Kmol) of 92.6% thick diketene, and all the other are all the same as embodiment 1, obtain 3575.4 kilograms of methyl acetoacetate products, product The content is 99.79%, and the yield is 93.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com