Patents

Literature

39results about How to "Avoid catalysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated ceramic catalyst supports and method

ActiveUS7166555B2Reduce penetrationReduce porosityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyvinyl alcoholMetallurgy

Porous ceramic catalyst supports are pre-coated with a passivation layer prior to applying a catalyst or catalyst support coating, the passivation layer consisting of a coating of a liquid mixture comprising at least one coating material selected from the group of polyvinyl alcohol / vinyl amine copolymer, polyvinyl alcohol / vinyl formamide copolymer, and gelatin.

Owner:CORNING INC

Coated ceramic catalyst supports and method

ActiveUS20060183632A1High coefficient of thermal expansionReduce air permeabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationMetallurgyPolyvinyl alcohol

Porous ceramic catalyst supports are pre-coated with a passivation layer prior to applying a catalyst or catalyst support coating, the passivation layer consisting of a coating of a liquid mixture comprising at least one coating material selected from the group of polyvinyl alcohol / vinyl amine copolymer, polyvinyl alcohol / vinyl formamide copolymer, and gelatin.

Owner:CORNING INC

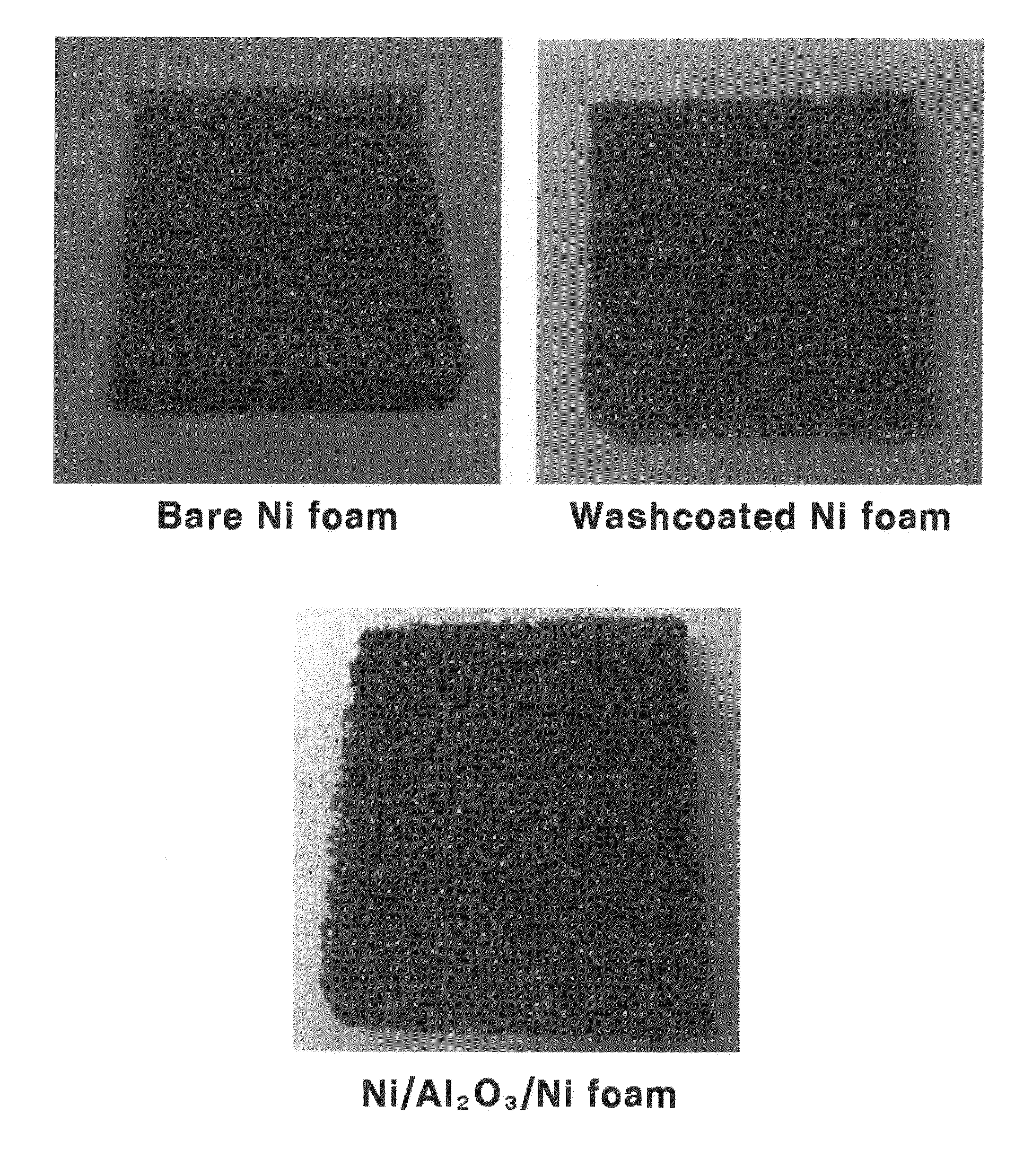

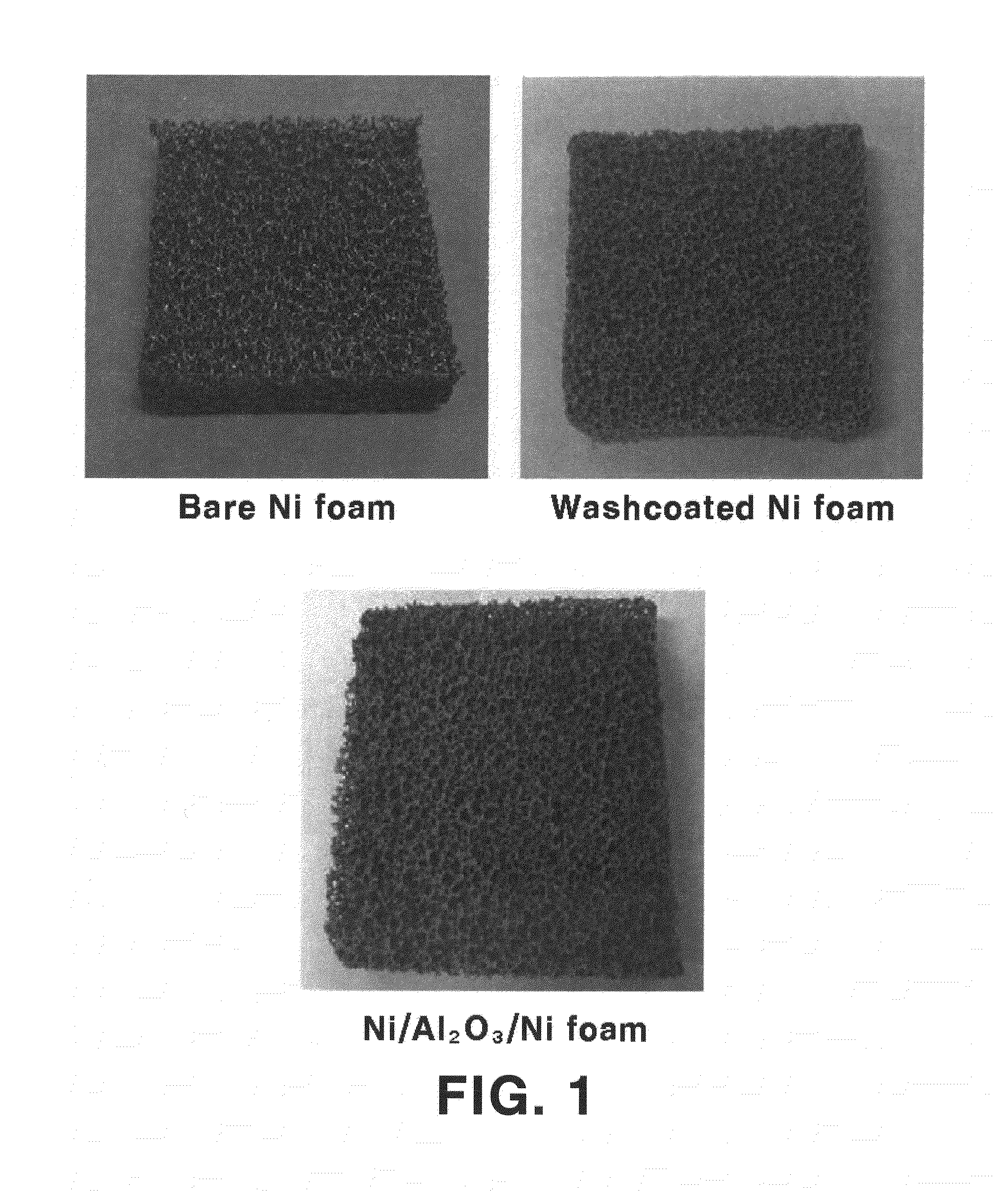

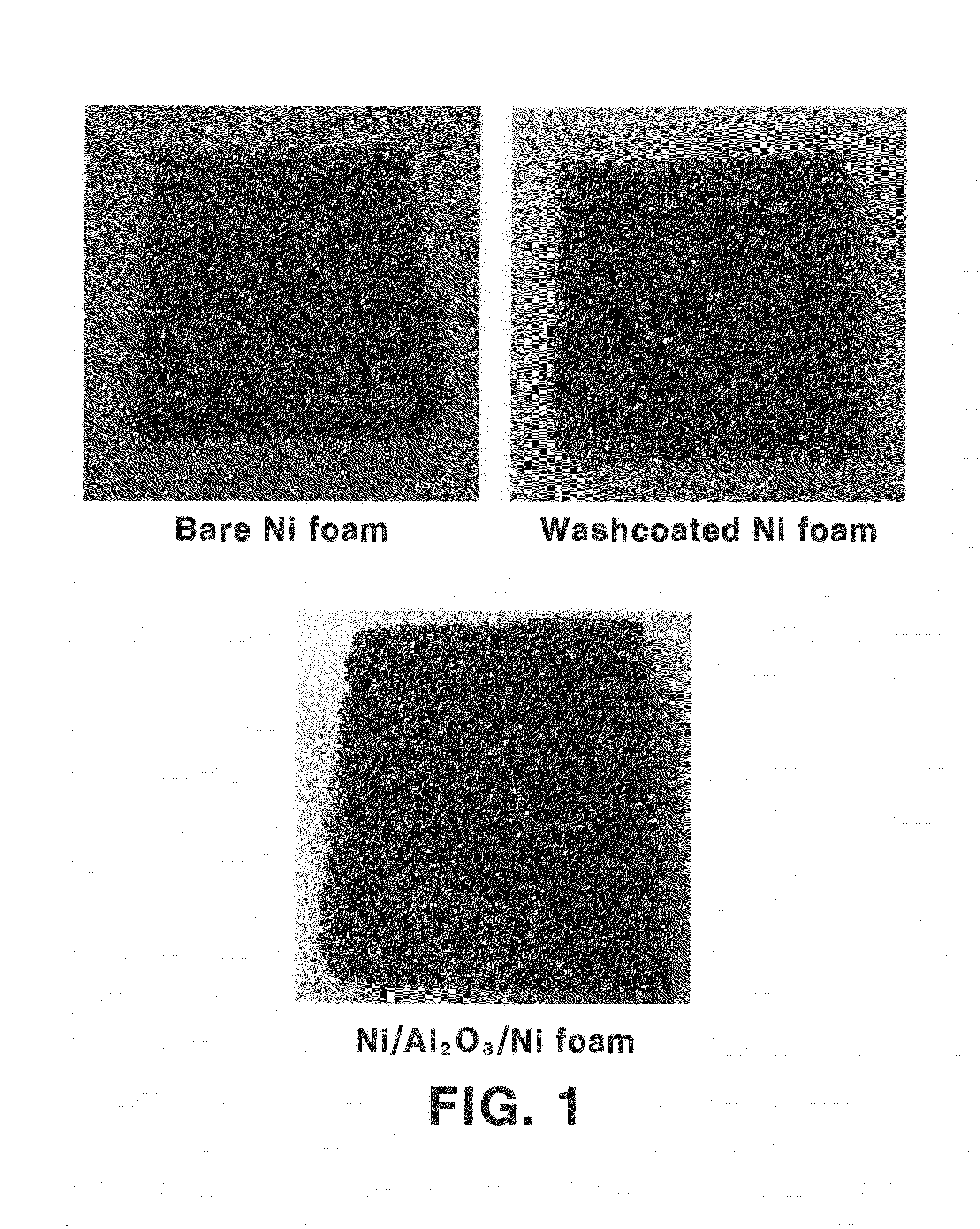

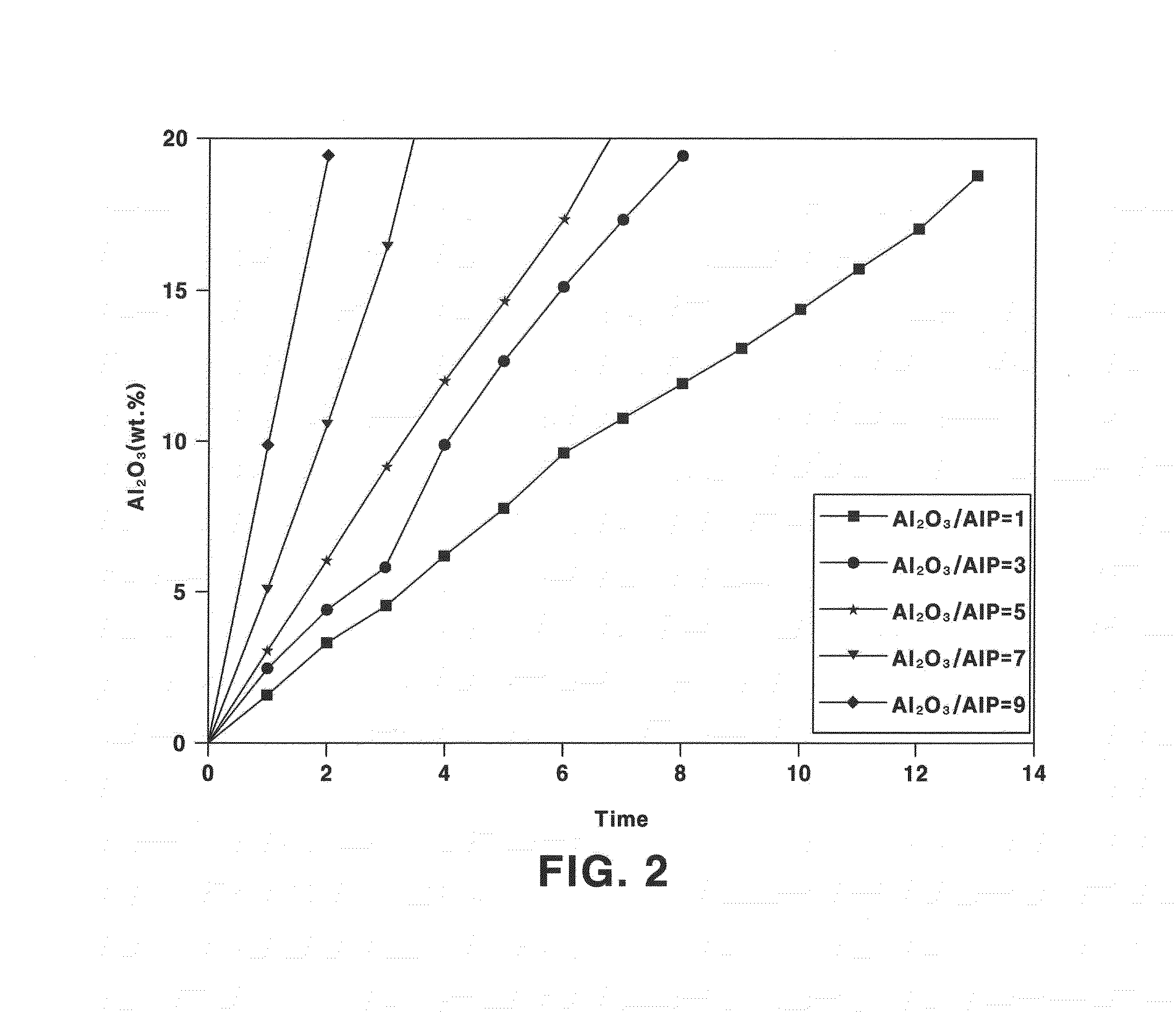

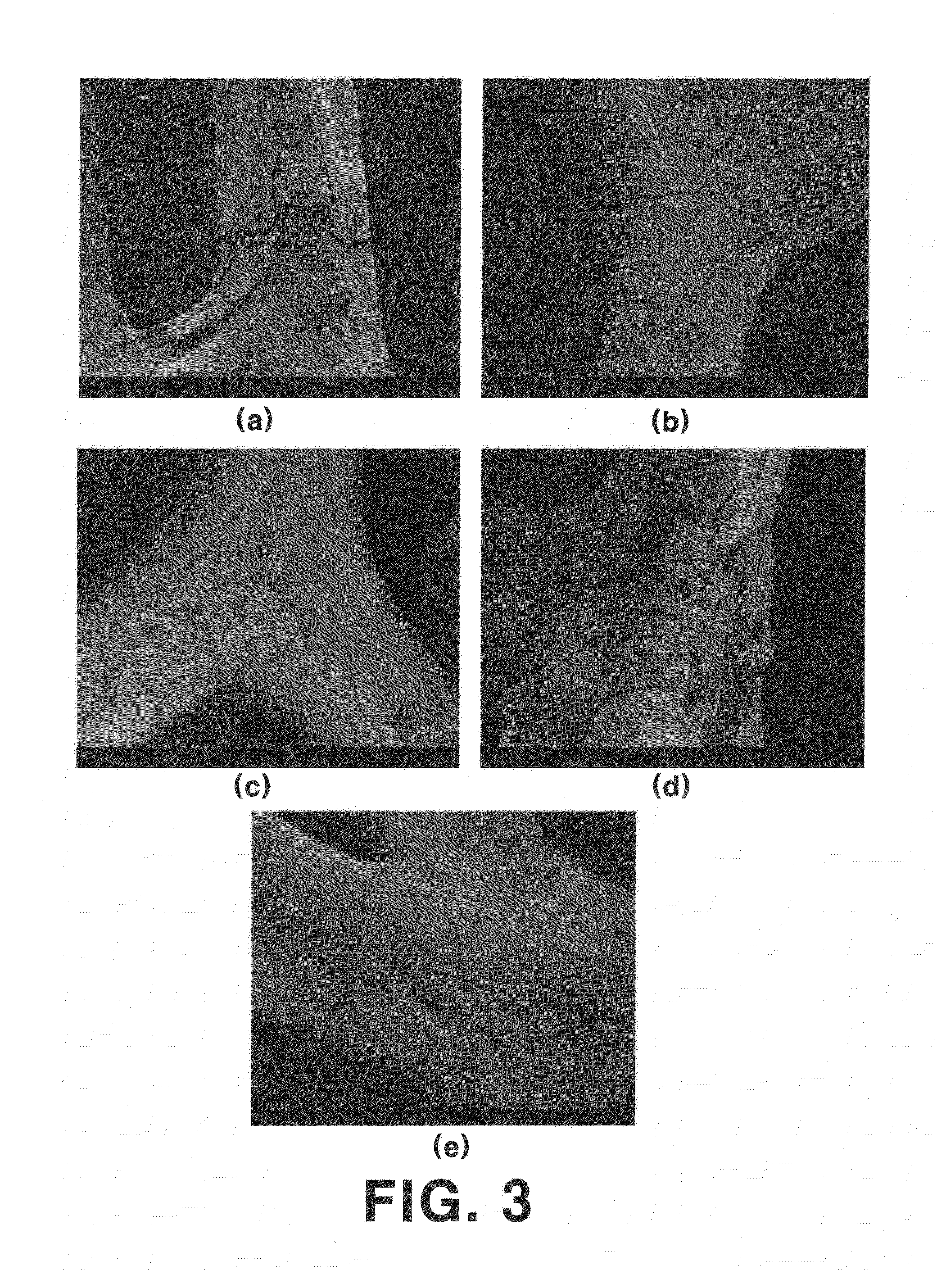

High-durability metal foam-supported catalyst for steam carbon dioxide reforming and method for preparing the same

Disclosed is a catalyst support for steam carbon dioxide reforming reaction utilizing the advantages of superior thermal conductivity and thermal dispersion of a metal foam support and a large specific surface area of a carrier material, which allows selective control of coating amount and the thickness of a support layer and prevents cracking on the support surface, using both the sol-gel method and the slurry method that have been used for coating of a metal foam support.

Owner:KOREA INST OF SCI & TECH

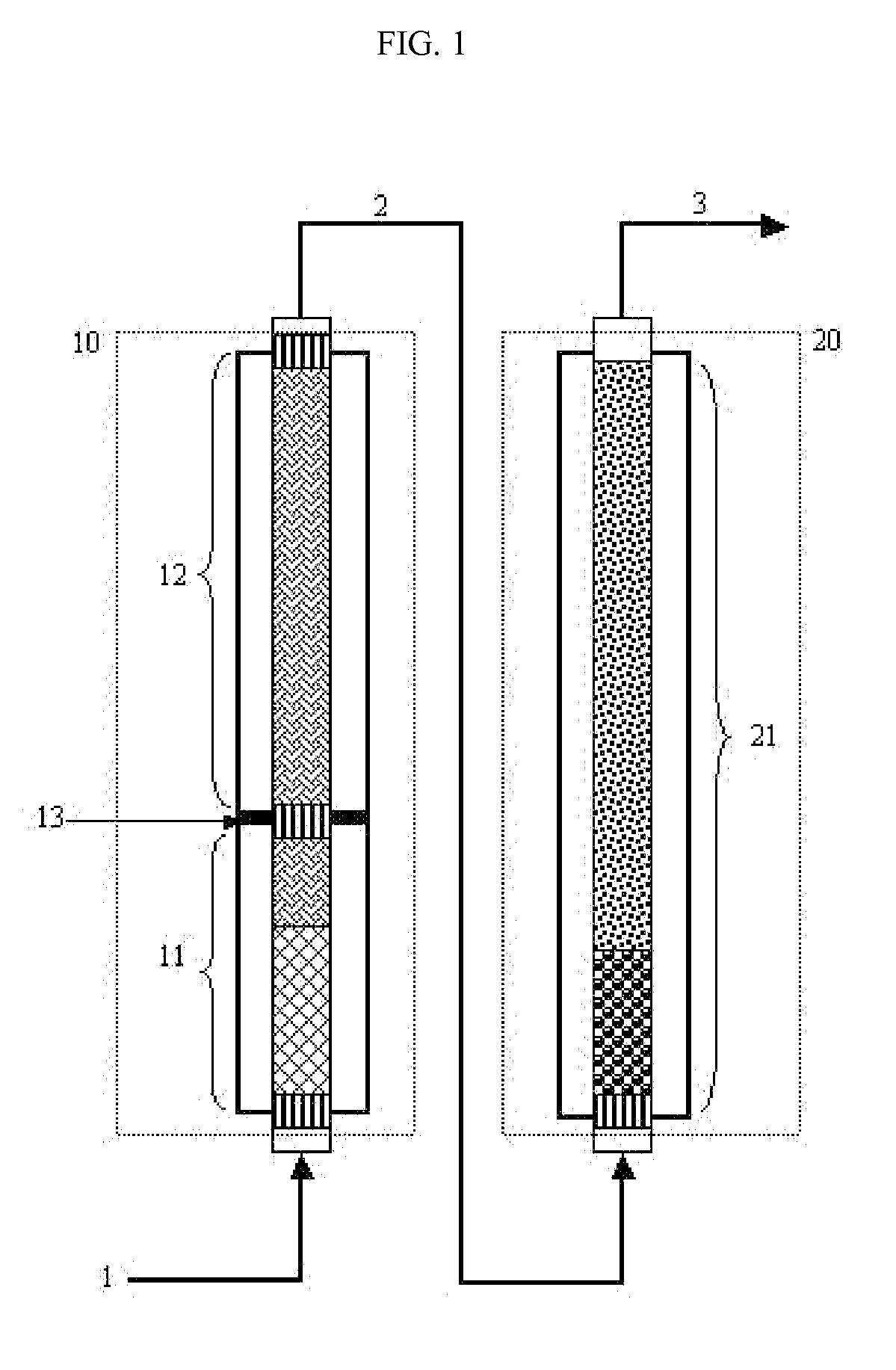

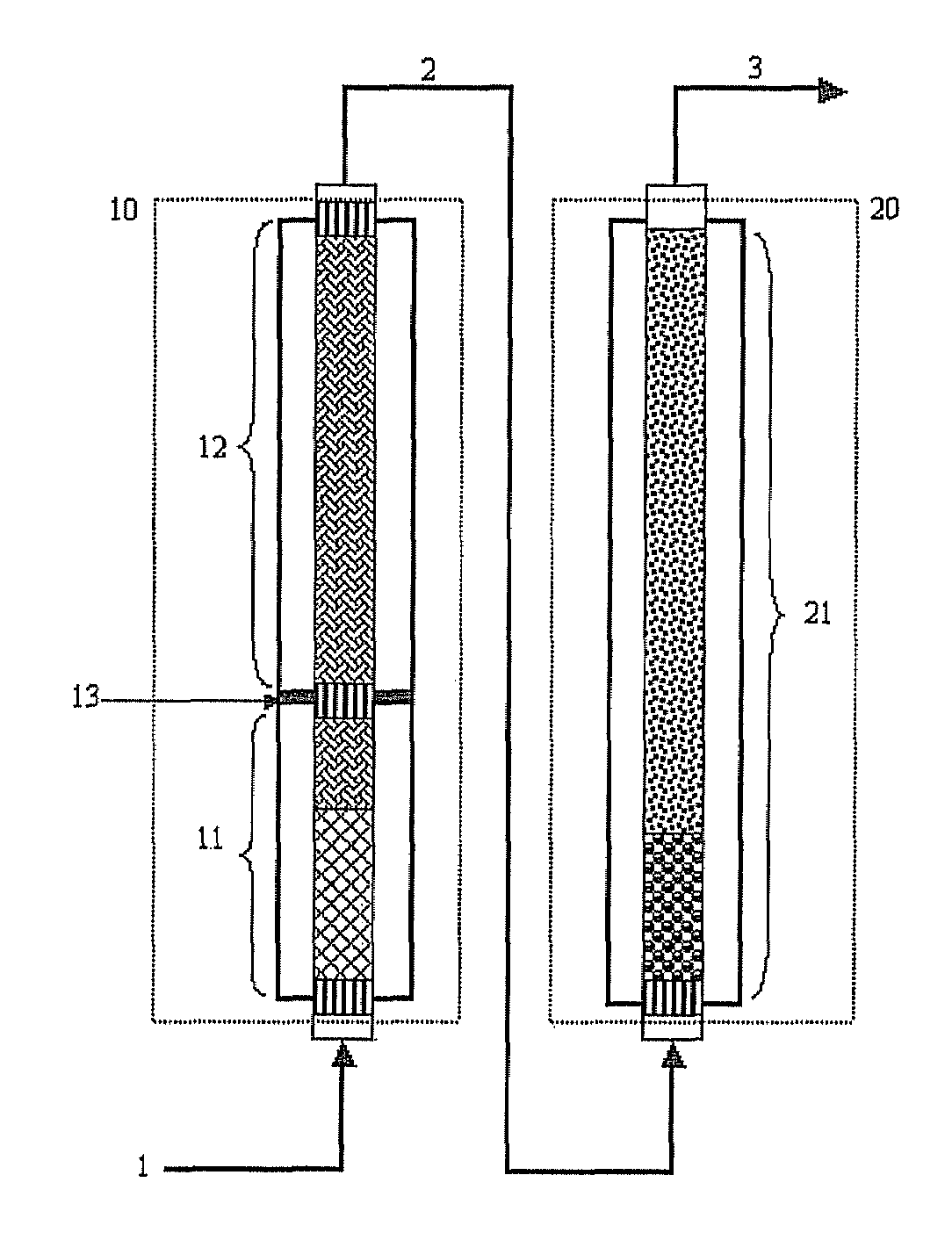

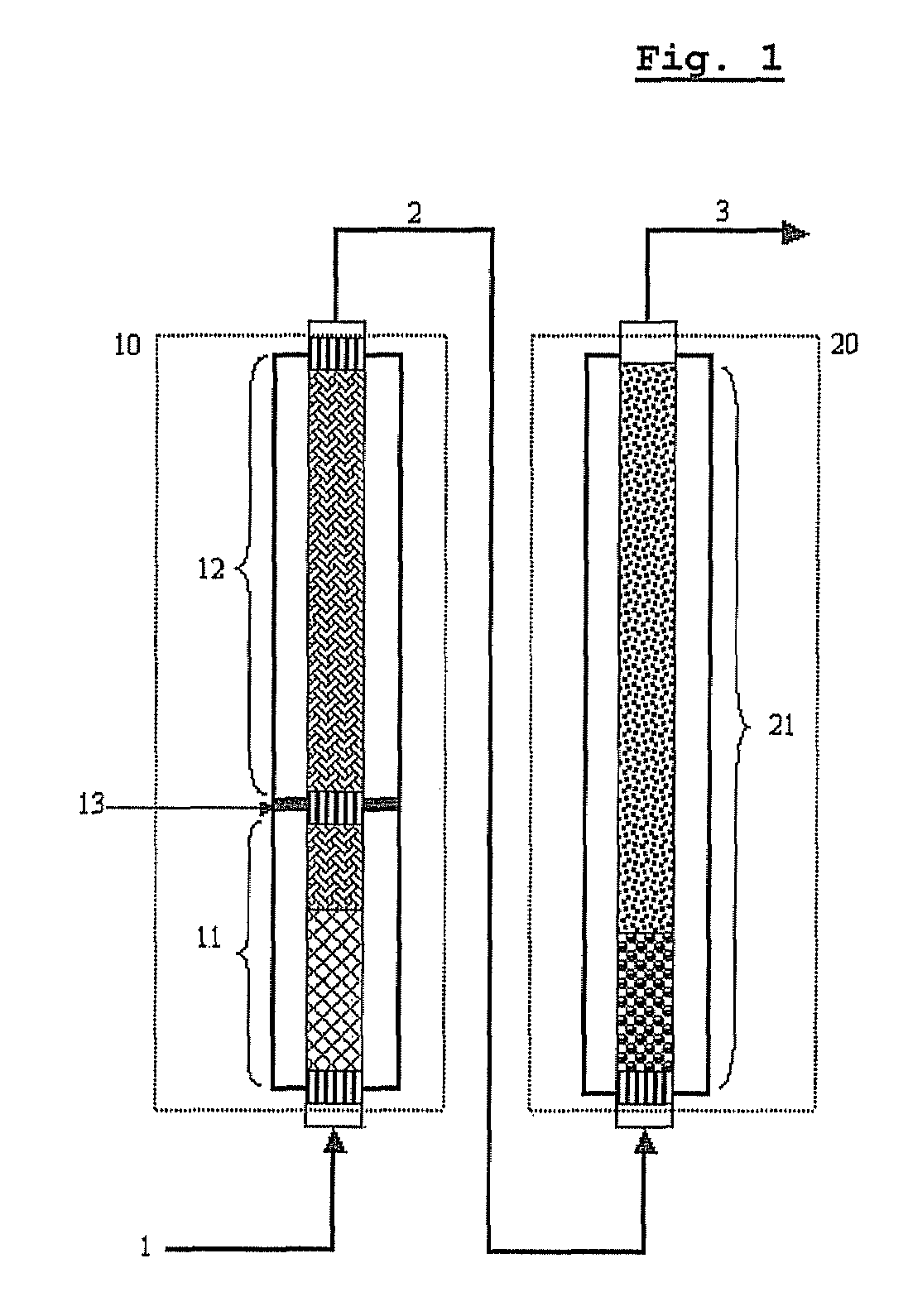

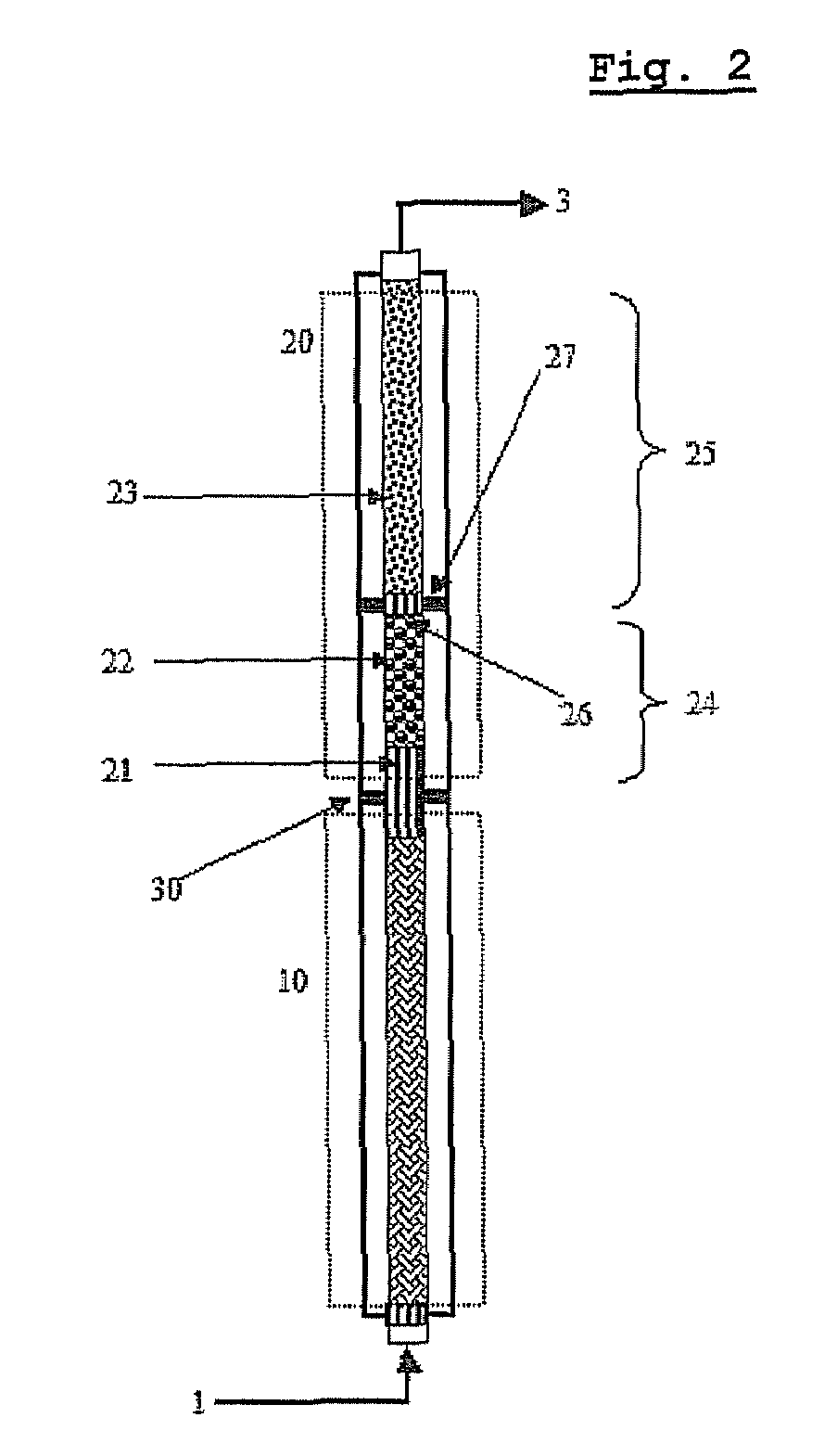

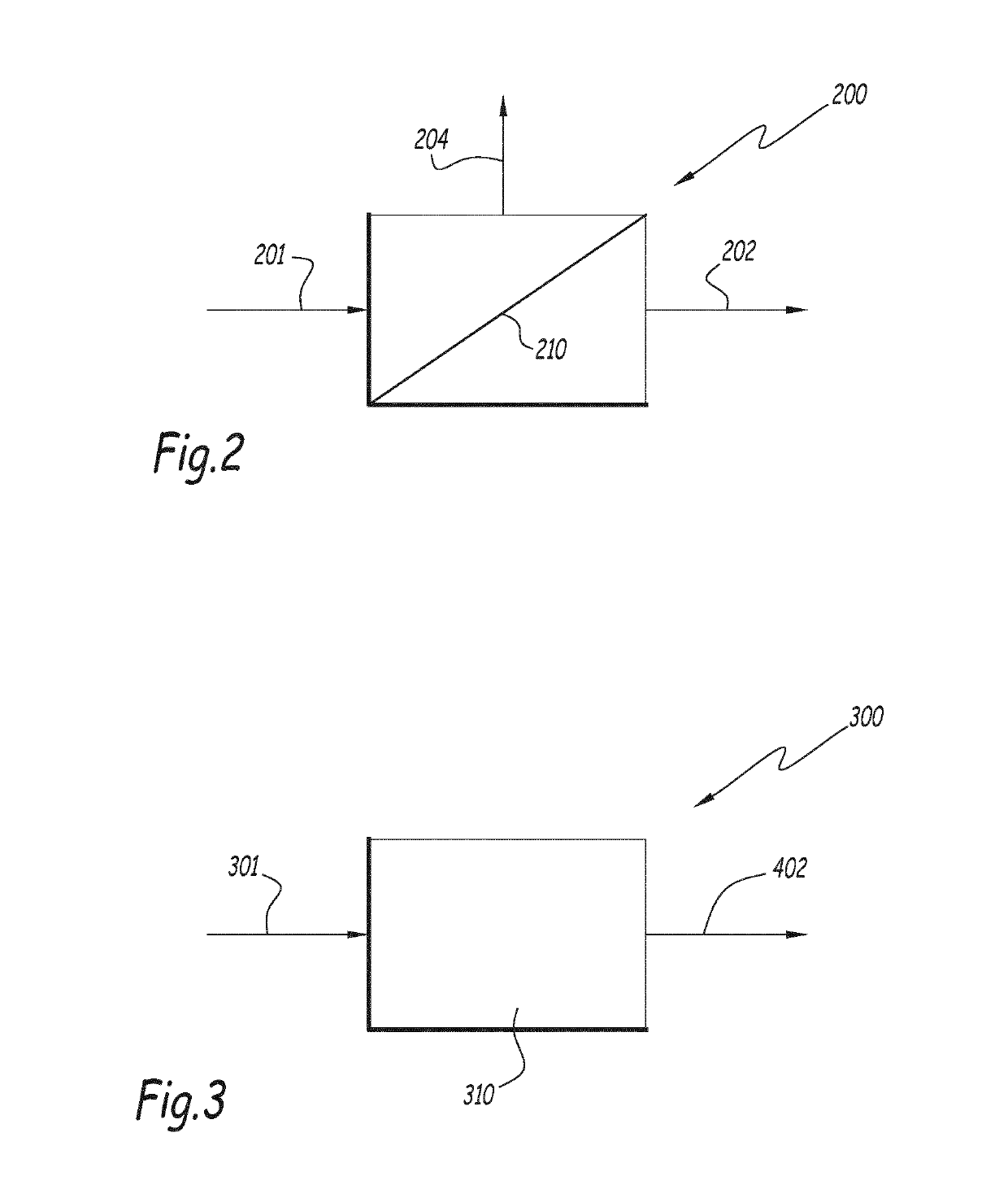

Method of producing unsaturated acid in fixed-bed catalytic partial oxidation reactor with high efficiency

InactiveUS20100015017A1Increase flexibilityLimit magnitudeOrganic compound preparationCarbonyl compound preparationShell and tube heat exchangerPartial oxidation

A shell-and-tube heat exchanger-type reactor including one or more catalytic tubes, each including a first-step reaction zone and a second-step reaction zone, wherein at least one of the first-step reaction zone and the second-step reaction zone is divided into two or more shell spaces by a partition; each of the divided shell spaces is independently heat-controlled; and a heat transfer medium having a temperature from the lowest active temperature of a catalyst layer in a reaction tube corresponding to the first shell space of the first-step reaction zone or the first shell space of the second-step reaction zone to the lowest active temperature of the catalyst layer plus 20° C.; and the first shell space of the first-step reaction zone or the first shell space of the second-step reaction zone is controlled so as to provide a reactant conversion contribution per length of 1.2˜2.5.

Owner:LG CHEM LTD

Repairing type lubricant additive and its preparation method

The present invention discloses a repairing type lubricating oil additive and its preparation method. Its composition includes 1-10% of aluminium, titanium, zinc and tin granules whose grain size is 10-200 nm, their weight ratio of 5.5-6.5:1.5-2.5:0.5-1.5:0.5-1.5, 88-98% of basis oil for finished product lubricating oil and 1-2% of dispersing additive. Its preparation method incldues the following steps: placing the above-mentioned all the materials into same container, mechanically-stirring and mixing for 20-40 min., placing the mixture and said container into an ultrasonic oscillator to make ultrasonic oscillation for 20-40 min. so as to obtain the invented lubricating oil additive with good repairing effects.

Owner:TIANJIN UNIV

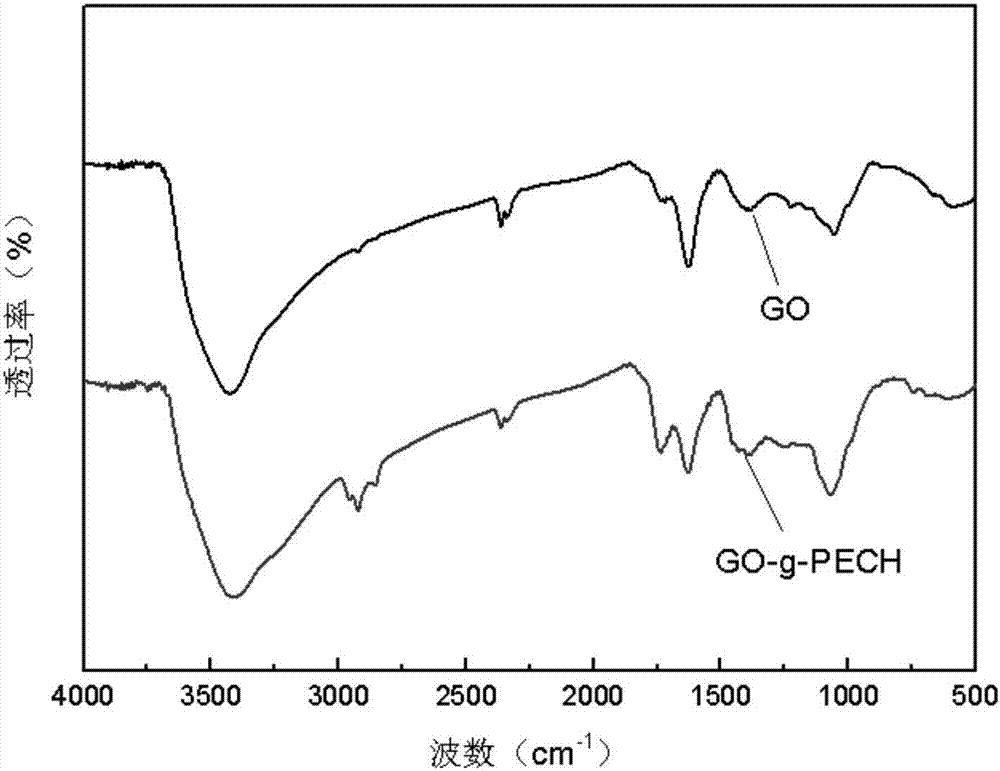

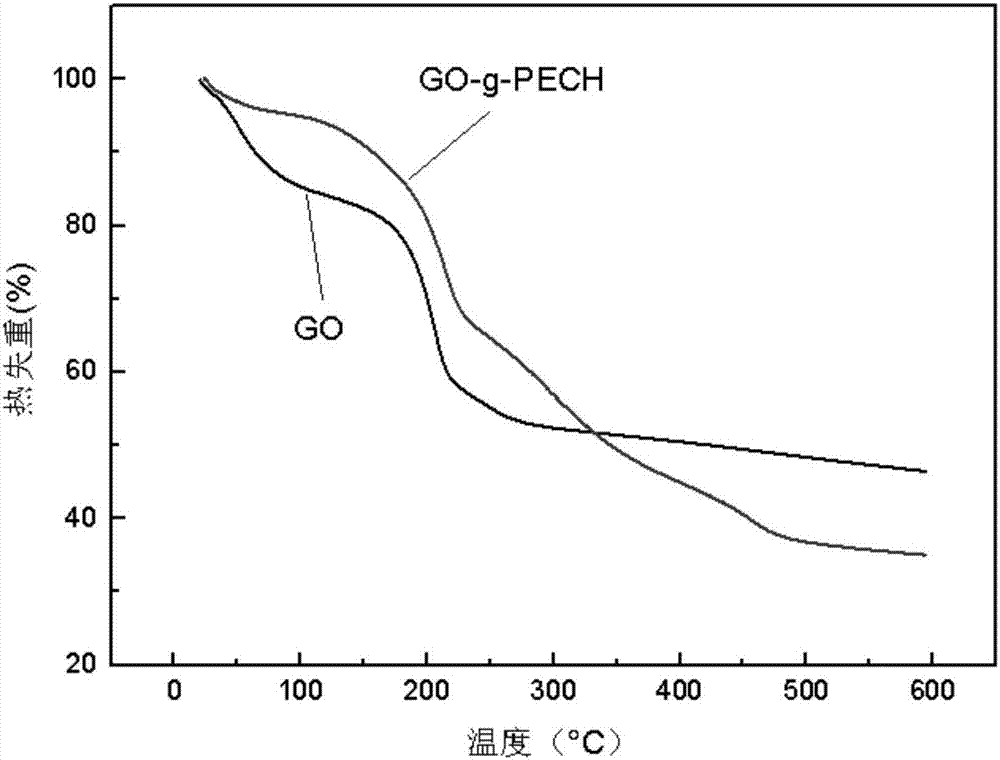

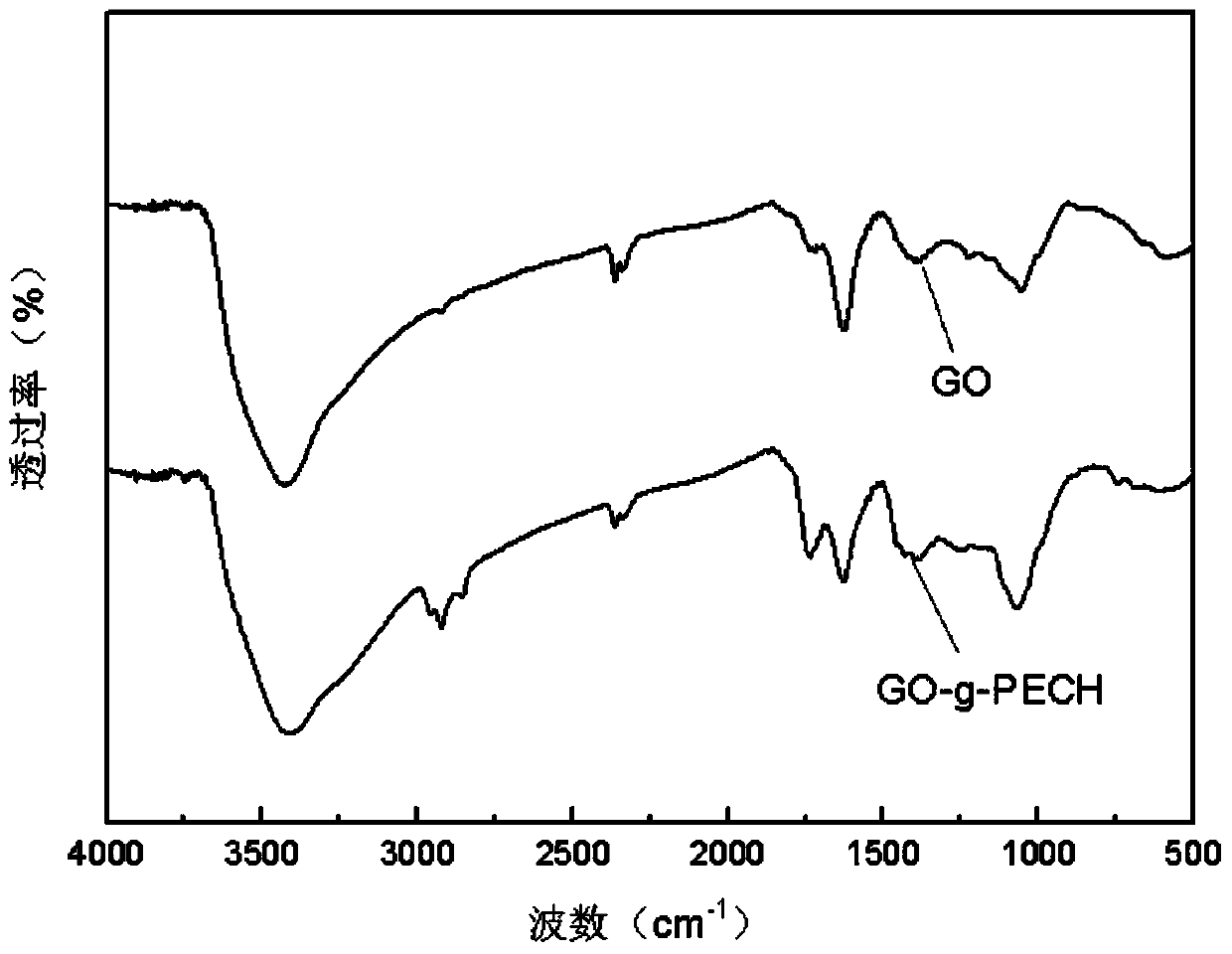

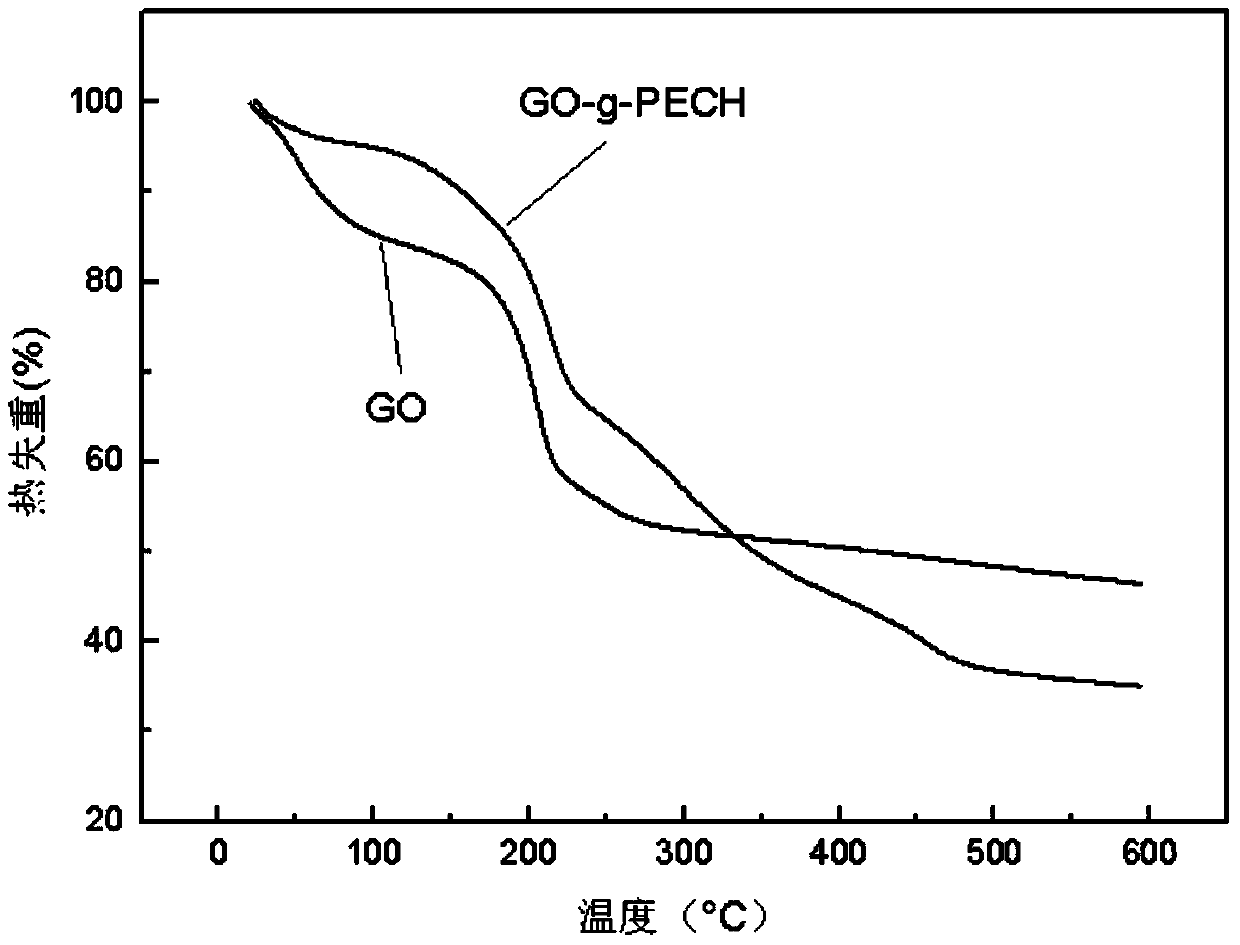

Method for initiating polymerization of epoxy monomer by using graphene oxide as initiator

ActiveCN107216461AAchieve surface modificationImprove interface performanceEpoxyCationic polymerization

The invention discloses a method for initiating polymerization of an epoxy monomer by using graphene oxide as an initiator. The method comprises the following steps: the epoxy monomer and the graphene oxide are added to a reaction system, wherein, the mass rate of the epoxy monomer to the graphene oxide is 300-5, the graphene oxide can prompt the epoxy monomer to undergo cationic ring-opening polymerization at the temperature of 0-100 DEG C, and the obtained epoxy polymer can be grafted in situ on the surface of a graphene oxide sheet layer, so that surface modification of the graphene oxide is realized, and cation-initiated polymerization and grafting amount are controlled by reaction time and reaction temperature.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Reinforced seamless steel pipe piercing plug and manufacturing method thereof

ActiveCN110205561AAvoid crackingHigh bonding strengthMandrelsMetallic material coating processesNiobiumRare earth

The invention discloses a reinforced seamless steel pipe piercing plug. The piercing plug comprises a piercing plug base body, wherein a transition layer and a reinforcing layer are sequentially arranged on the outer surface of the piercing plug body from inside to outside; the transition layer is manufactured from the following components in parts by weight: 61.0%-79.0% of Fe, 5.0%-10.0% of Co, 10.0%-15.0% of Cr, 5.0%-10.0% of Mo, and 1.0%-4.0% of Ni; and the reinforcing layer is composed of, by mass, 96% of main materials and 4% of additives, specifically, the main materials comprise the following components in parts by weight: 20.0%-30.0% of Co, 20.0%-30.0% of Ni, 15.0%-20.0% of Cr, 5.0%-5.5% of Nb, 1.0%-2.5% of Si, 1.0%-2.0% of W, 1.0%-1.8% of C, 3.5%-5.0% of B, 0.5%-0.9% of rear earth, and 2.3%-30.7% of Fe. The piercing plug has good strength and hardness as well as higher high-temperature resistance, the friction of the piercing plug and the steel pipe is reduced, and the qualityof the inner wall of the steel pipe is improved, so that the workload for subsequent processing of the steel pipe is reduced; and moreover, the amount of steel adhering to the surface of the piercingplug is reduced, and the workload of workers is reduced as well.

Owner:芜湖点金机电科技有限公司

Method of producing unsaturated acid in fixed-bed catalytic partial oxidation reactor with high efficiency

ActiveUS7608734B2Increase flexibilityLimit magnitudeOrganic compound preparationCarbonyl compound preparationPartial oxidationShell and tube heat exchanger

Disclosed is a process for producing unsaturated aldehydes and / or unsaturated acids from olefins or alkanes in a fixed bed shell-and-tube heat exchanger-type reactor by catalytic vapor phase oxidation. A heat exchanger-type reactor for use in such a process is also disclosed. The process utilizes at least one first-step reaction zone and a second-step reaction zone that is divided into two or more shell spaces by at least one partition. The process may be applied to a single-step process for producing unsaturated acids from alkanes or alkenes.

Owner:LG CHEM LTD

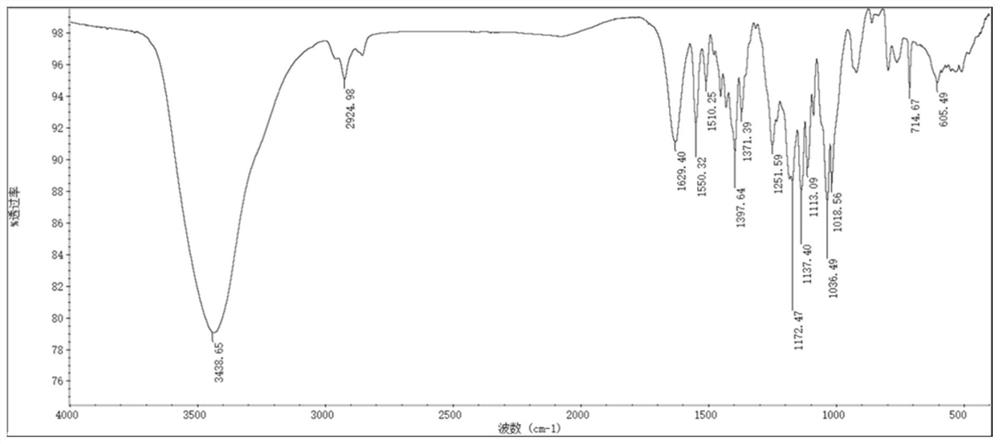

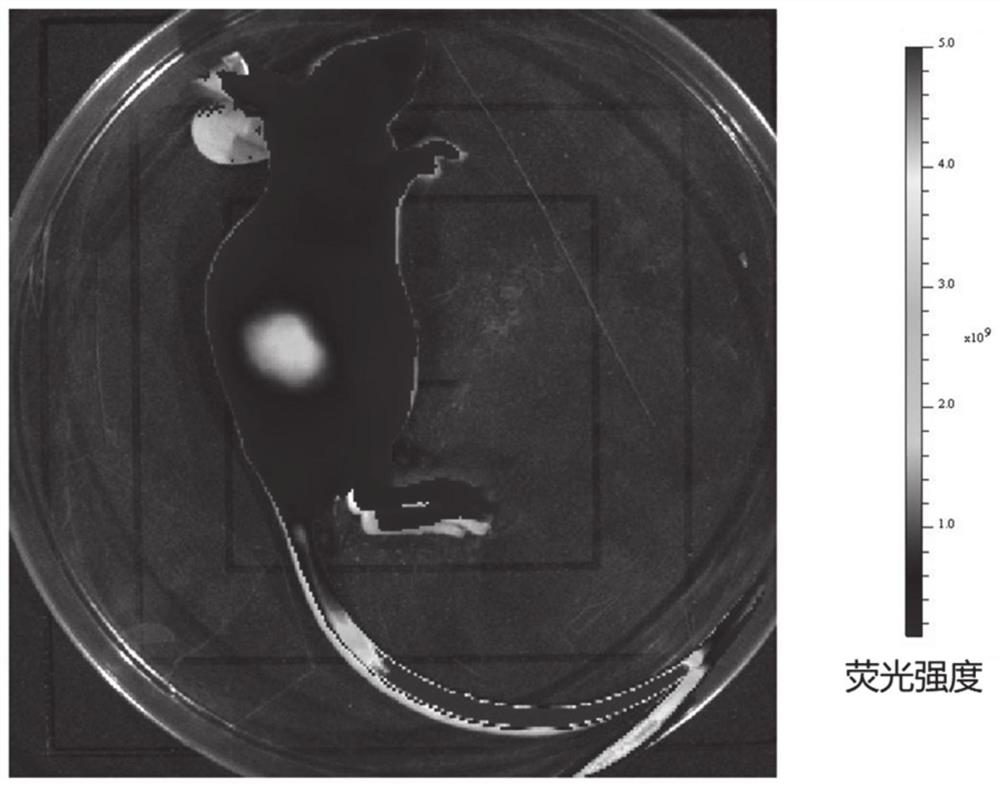

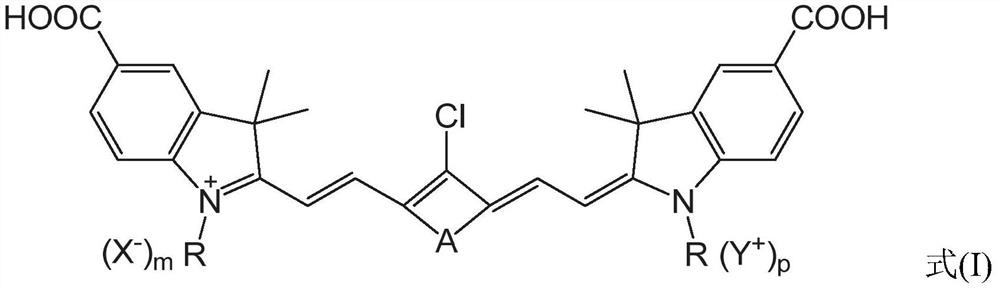

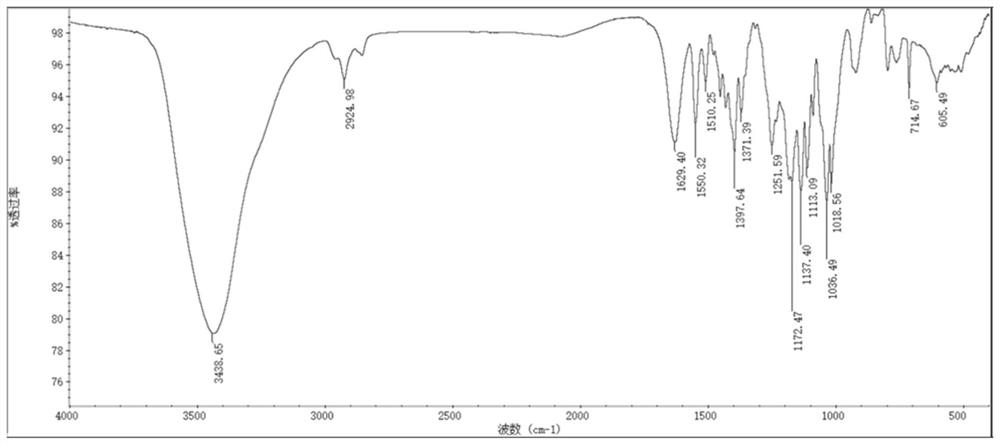

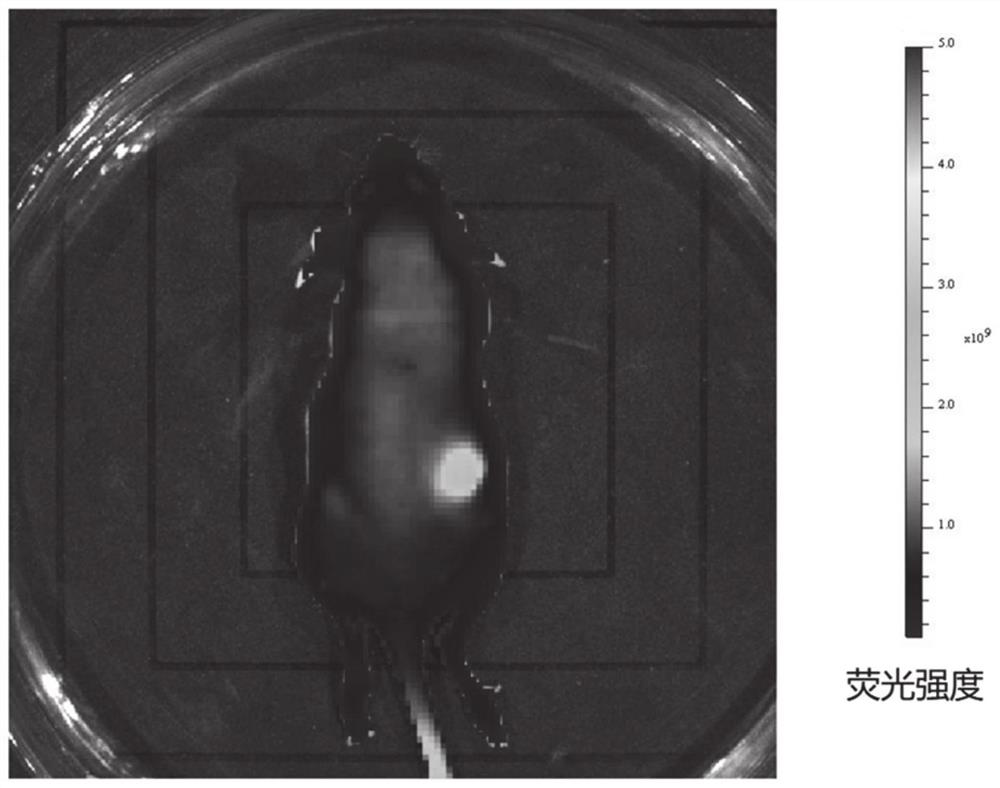

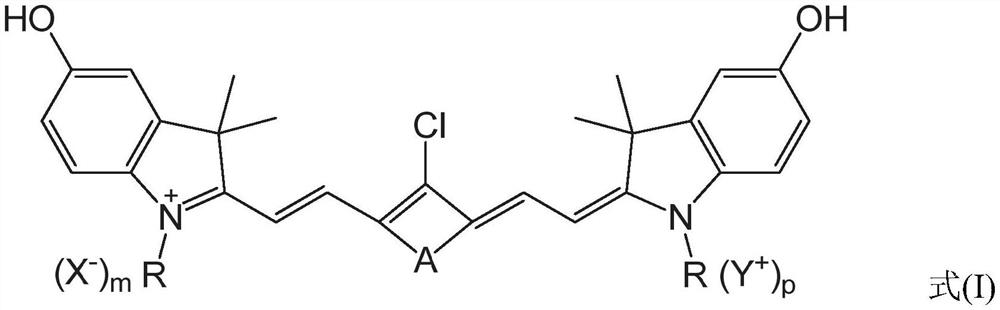

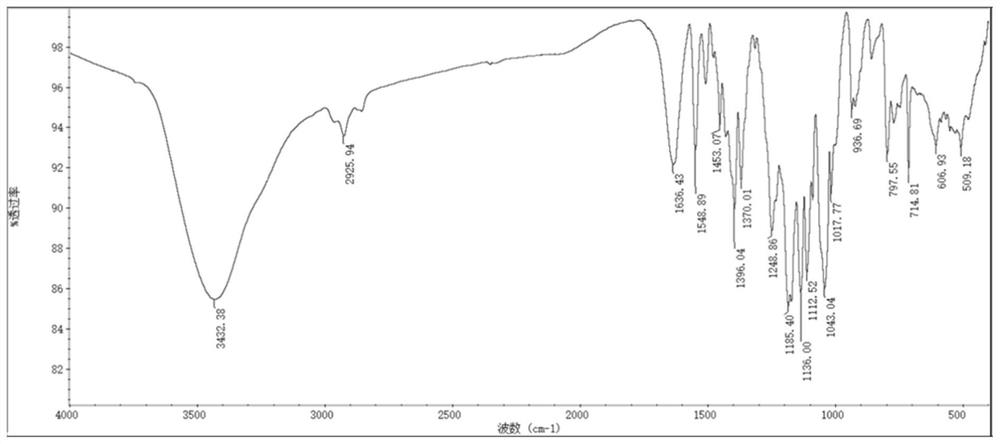

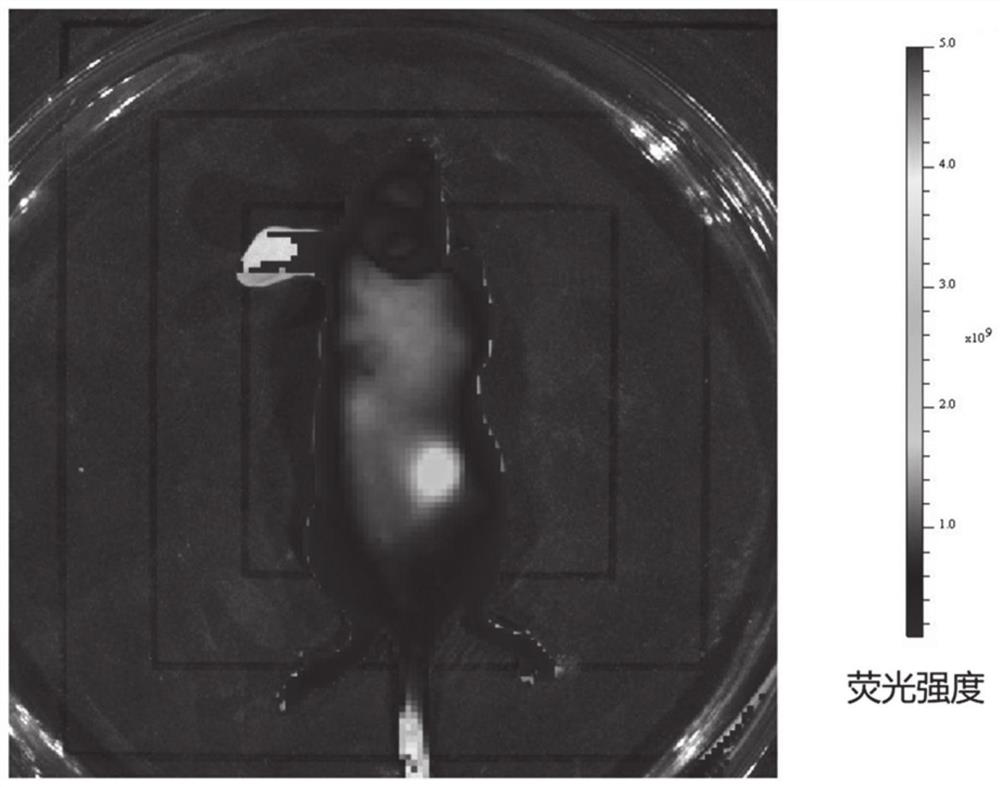

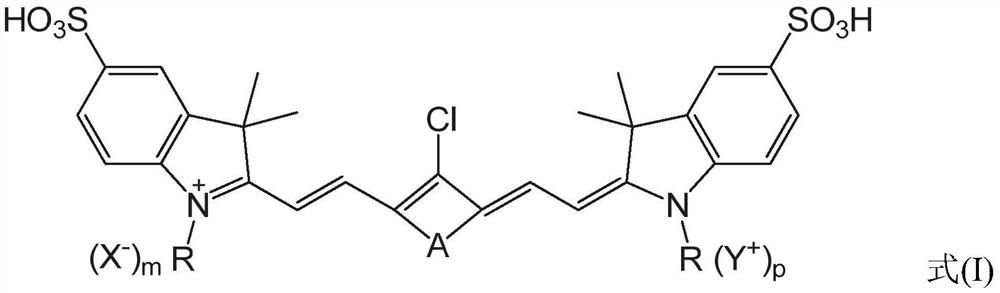

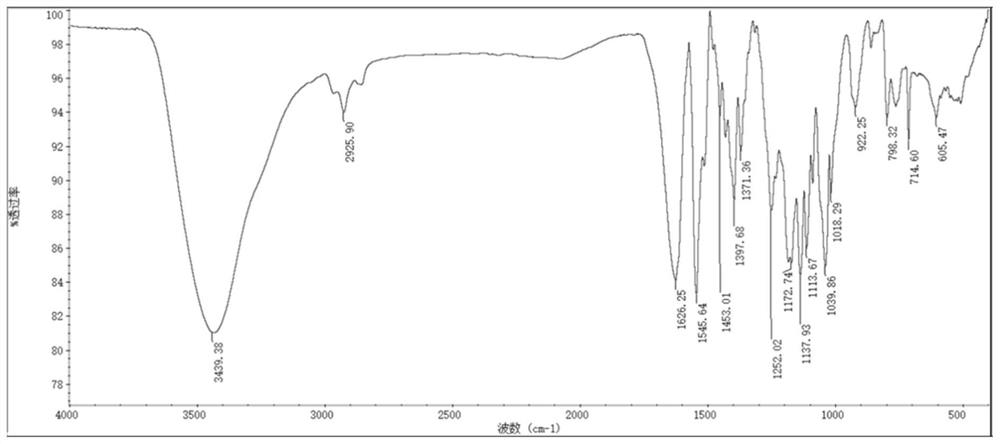

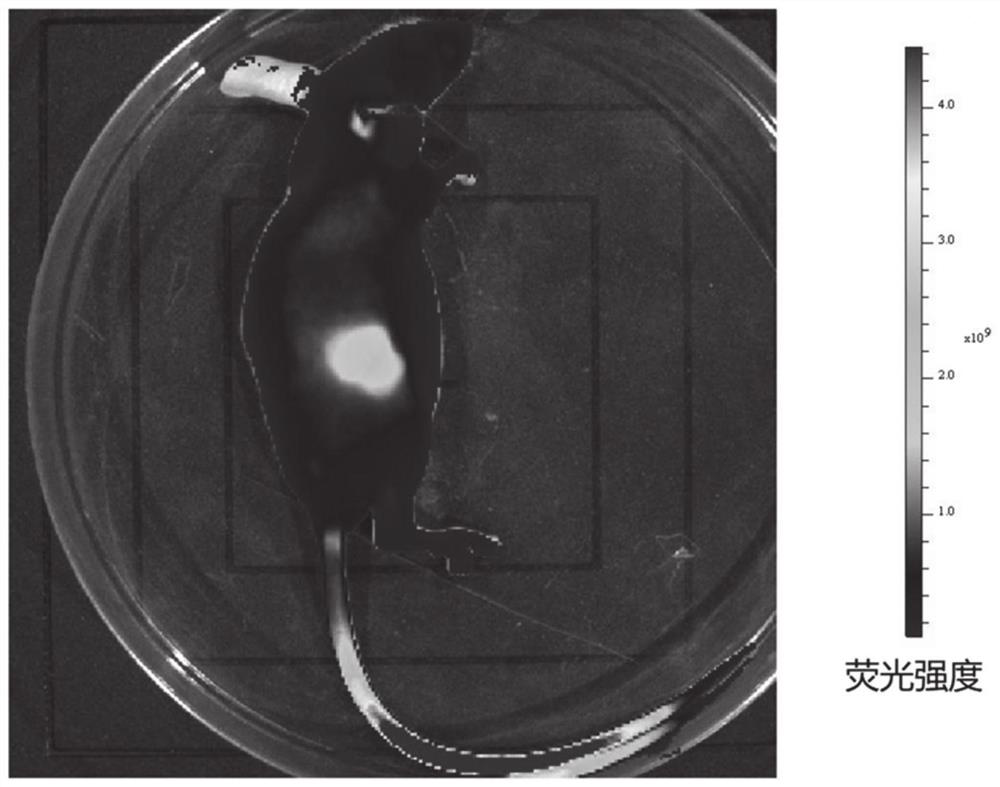

Heptamethine carboxyl indocyanine dye, preparation method and application thereof

PendingCN111662567AWith near-infrared light absorptionWith fluorescence imagingOrganic chemistryMethine/polymethine dyesCycloalkeneCarboxyl radical

The invention discloses a heptamethine carboxyl indocyanine dye, a preparation method and application thereof, and belongs to the field of polymethine indocyanine dyes and preparation thereof, whereinthe structural formula of the heptamethine carboxyl indocyanine dye is represented by a formula (I), and the dye has near-infrared light absorption and fluorescence development properties, and can beused as a probe auxiliary agent. The preparation method of the dye comprises the following steps: 1) carrying out a heating reaction on raw materials containing a 2,3,3-trimethyl-carboxyl indole derivative and a nucleophilic substituted compound under a vacuum condition to obtain an organic ammonium salt; and 2) carrying out a heating reaction on a solution containing the organic ammonium salt obtained in the step (1) and a cycloalkene derivative under a closed condition. The method has the advantages of short synthesis route, environment-friendly solvent, simple process, avoidance of noble metal catalysis, high yield, high purity and the like, is high in applicability, and can be used for synthesizing products of various structure types.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

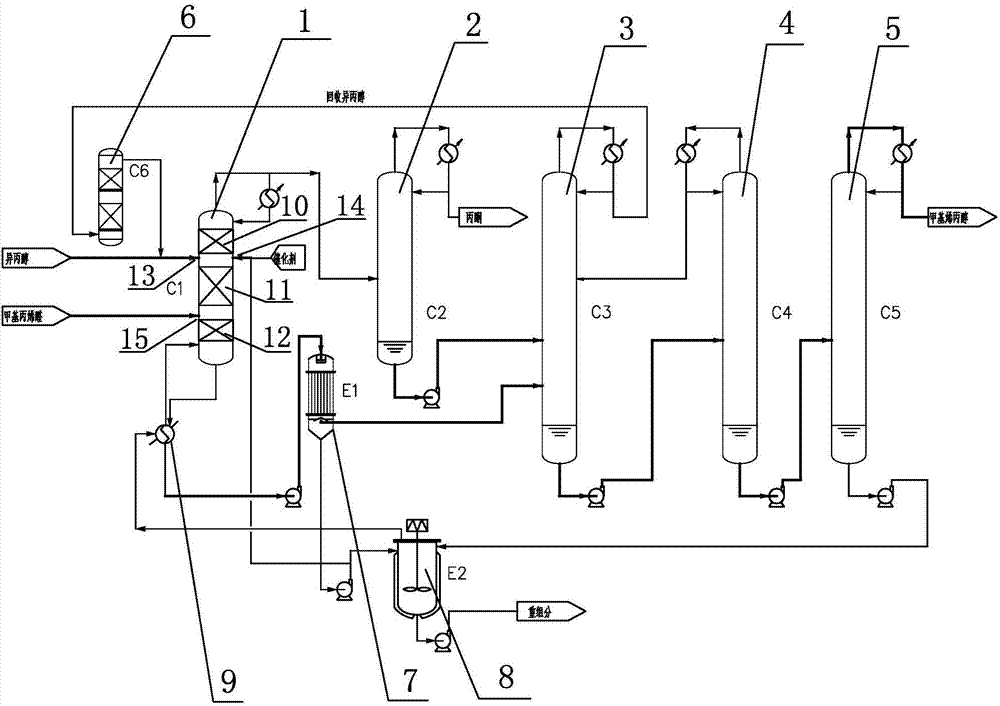

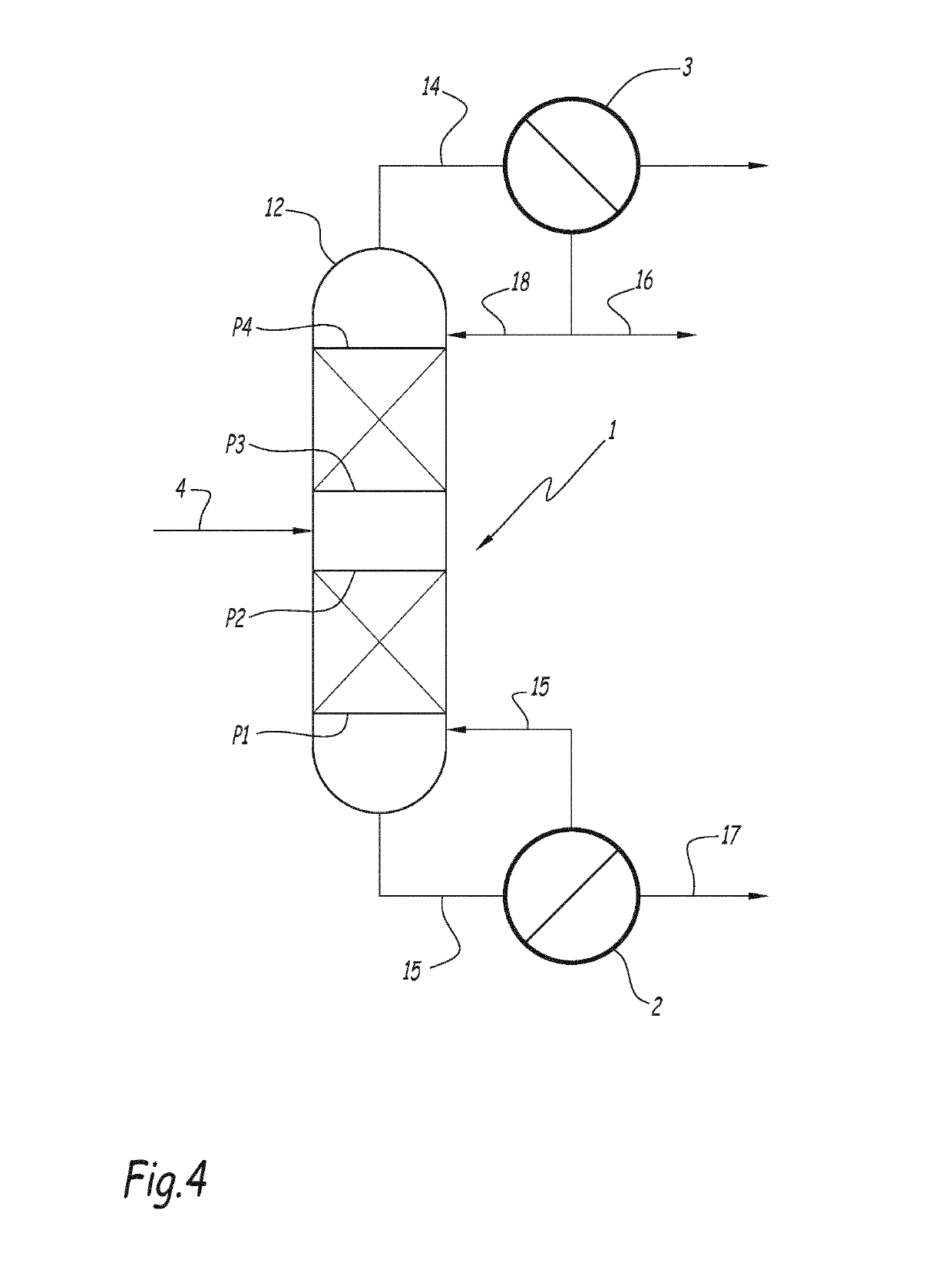

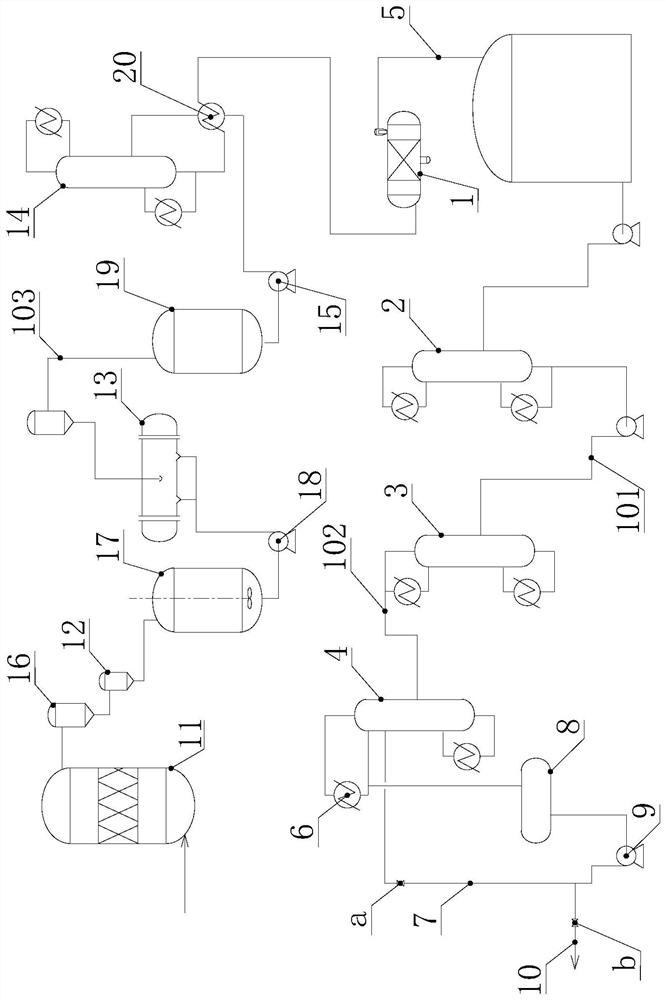

Production system and method for methylallyl alcohol

ActiveCN107365245ASeparation in timePromote positive progressOrganic compound preparationPreparation by dehydrogenationMolecular sieveGas phase

The invention discloses a production system and method for methylallyl alcohol. The production system is characterized by comprising a reactive distillation tower, an acetone product tower, an isopropanol recovery tower, a methylallyl alcohol light-component removing tower, a methylallyl alcohol product tower, a molecular sieve dehydration tower, a falling-film evaporator and a film evaporator. The refining method comprises the following steps: feeding each raw material into the reactive distillation tower, conveying a gas phase generated after a reaction into an acetone separation tower, and conveying a liquid phase to the falling-film evaporator; conveying a gas phase obtained after separation by the acetone separation tower into the acetone product tower, and returning a material at the bottom of the acetone separation tower to the reactive distillation tower; collecting acetone at the top of the acetone product tower, and conveying a material at the bottom of the acetone product tower to the isopropanol recovery tower; returning circulating acetone obtained at the top of the isopropanol recovery tower to the reactive distillation tower for participation in the reaction, and conveying a material obtained at the bottom of the isopropanol recovery tower to the methylallyl alcohol light-component removing tower; returning light components obtained at the top of the methylallyl alcohol light-component removing tower to the isopropanol recovery tower, and conveying a material obtained at the bottom of the methylallyl alcohol light-component removing tower to the methylallyl alcohol product tower; and collecting a methylallyl alcohol product from the top of the methylallyl alcohol product tower. The production system and method provided by the invention have the advantage of high conversion efficiency and high product purity.

Owner:齐翔华利新材料有限公司

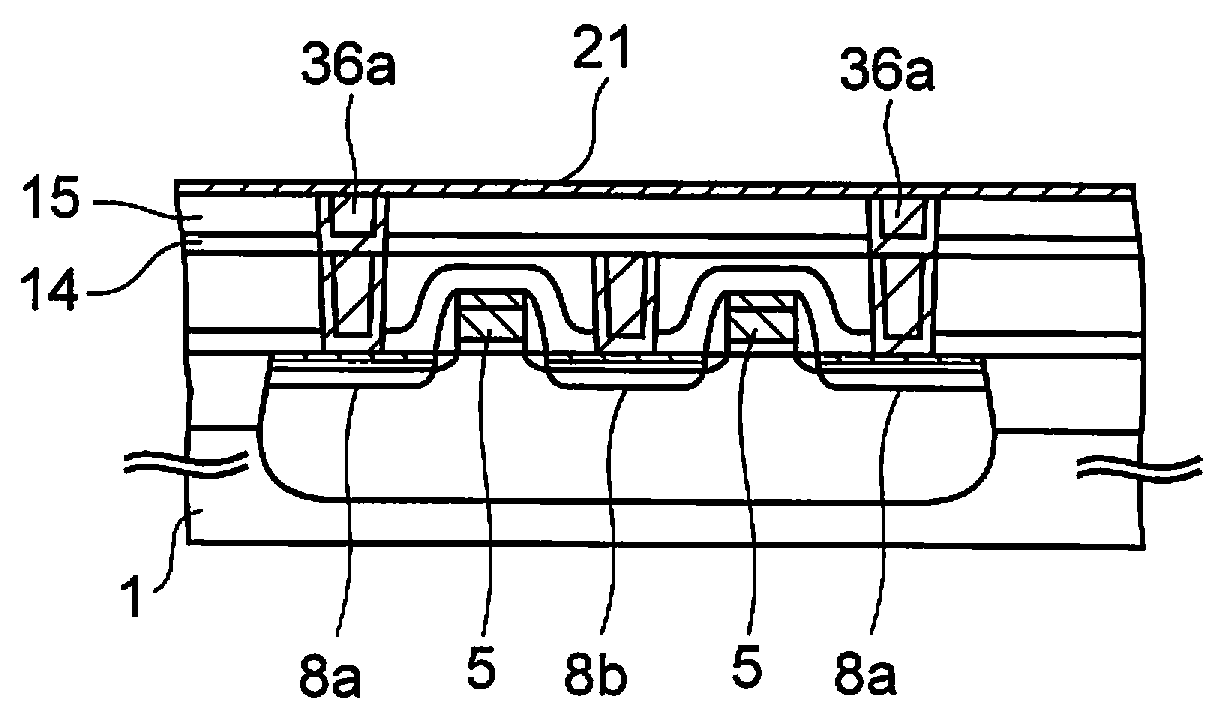

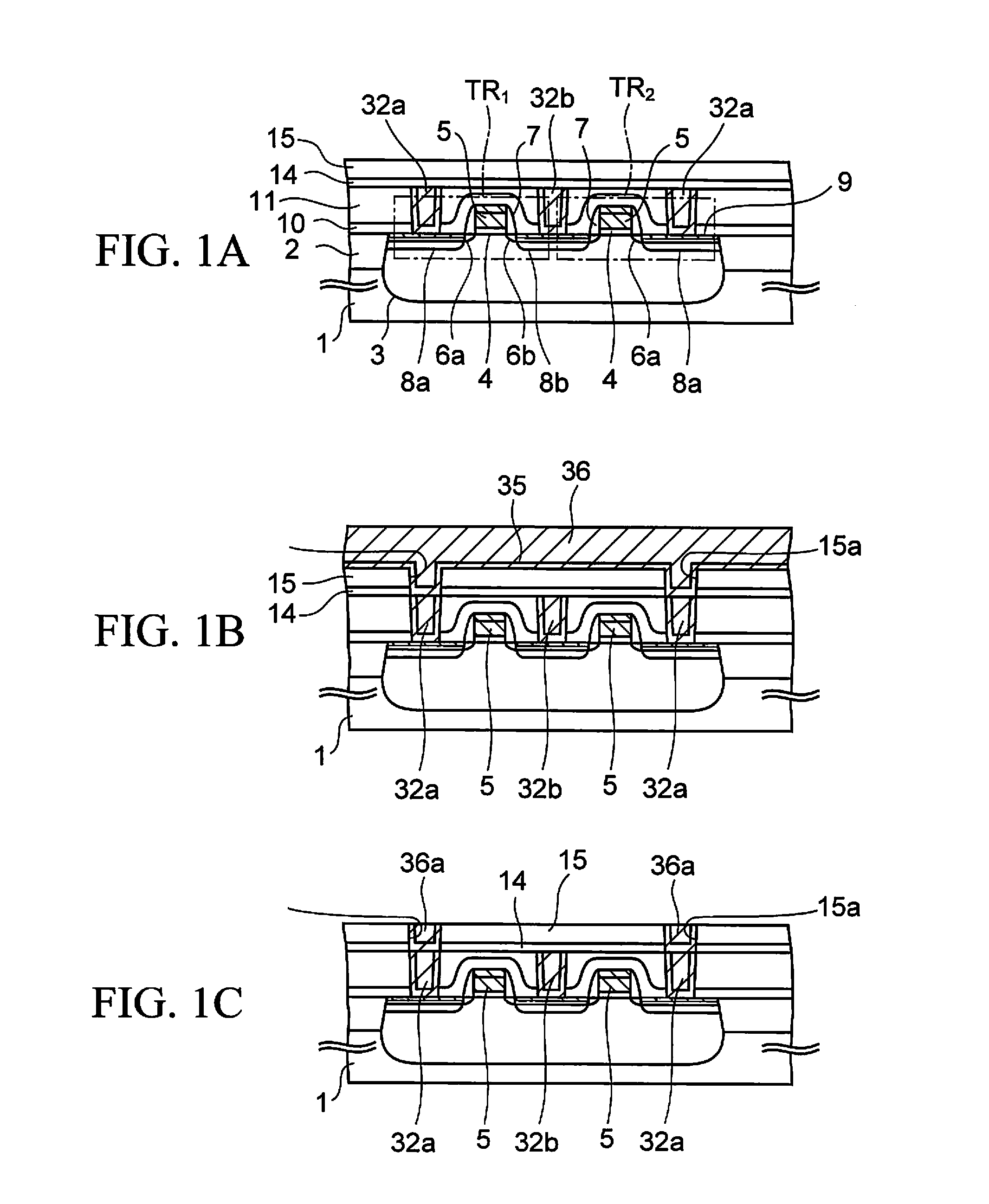

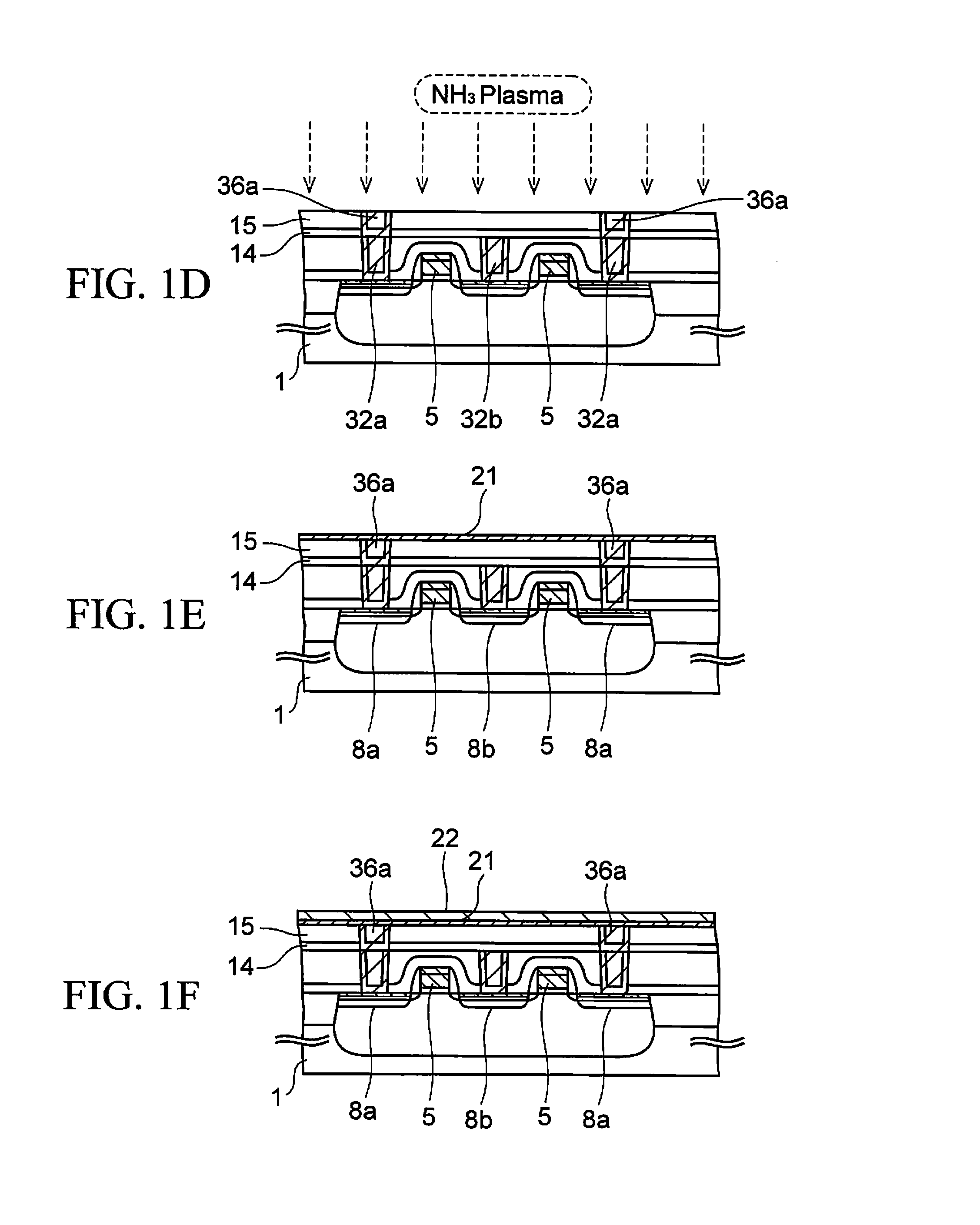

Method of manufacturing semiconductor device

InactiveUS7550302B2Improve charging capacityTotal current dropSemiconductor/solid-state device manufacturingCapacitor with voltage varied dielectricFerroelectric thin filmsSilicon

The present invention provides a method of manufacturing a semiconductor device. The method includes the steps of forming a first interlayer insulating film over a silicon substrate; forming a first conductive film on the first interlayer insulating film; forming a first ferroelectric film, which is crystallized, on the first conductive film; annealing the first ferroelectric film; after the annealing, forming, on the first ferroelectric film, a second ferroelectric film made of an amorphous material or a microcrystalline material; forming a second conductive film on the second ferroelectric film; and forming a capacitor by patterning the first and second conductive films and the first and second ferroelectric films.

Owner:FUJITSU SEMICON LTD

Method for producing xylylene diisocyanate (XDI)

InactiveUS20190135737A1High yield rateImprove behaviorSemi-permeable membranesOrganic compound preparationXylylenePolymer science

Disclosed is to a method for producing xylylene diisocyanate (XDI), in particular meta-xylylene diisocyanate (mXDI), including the following steps: a) phosgenation of xylylene-diamine (XDA), in particular m-xylylene-diamine (mXDA) in the case of mXDI; b) eliminating the hydrochloric acid from the reaction medium obtained in step (a) at a temperature of between 120 and 190° C. and a pressure of between 1 mbar and 20 bar.

Owner:VENCOREX FRANCE

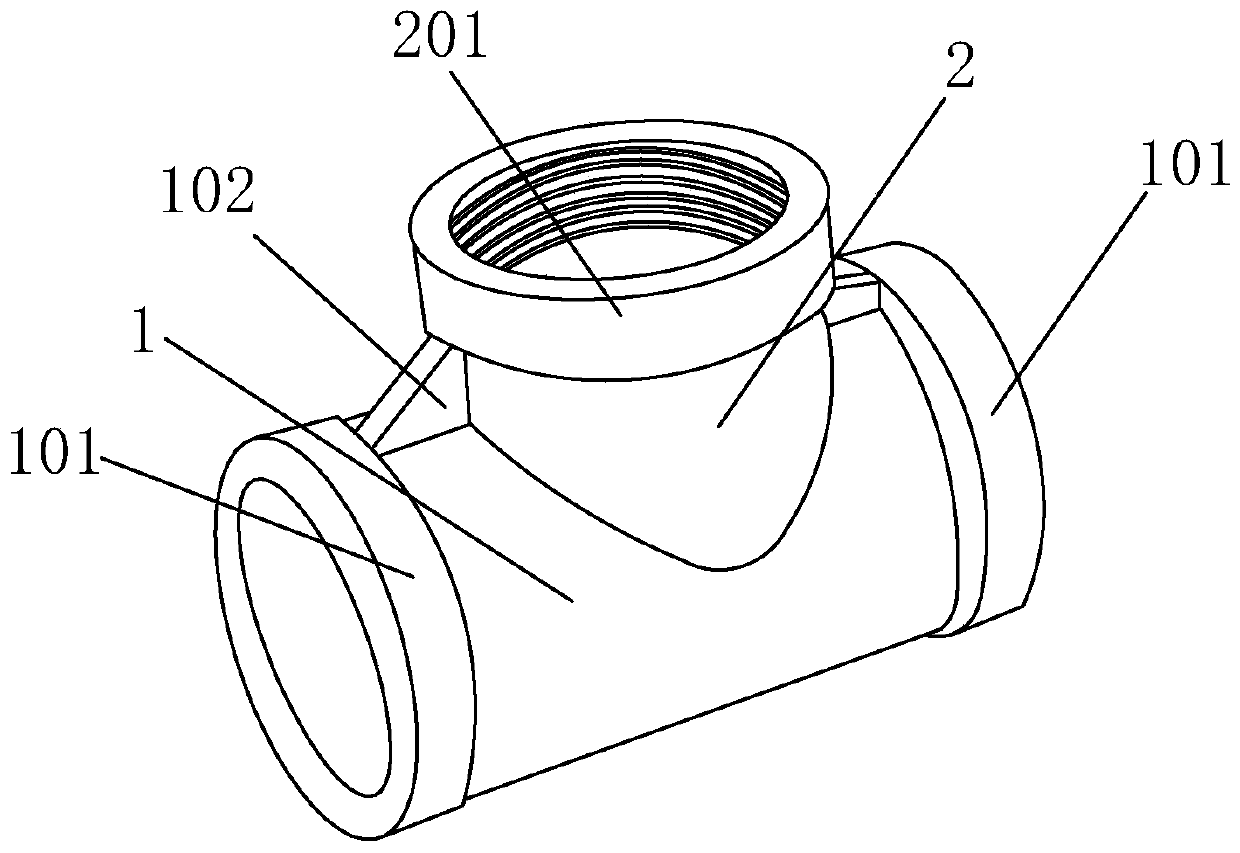

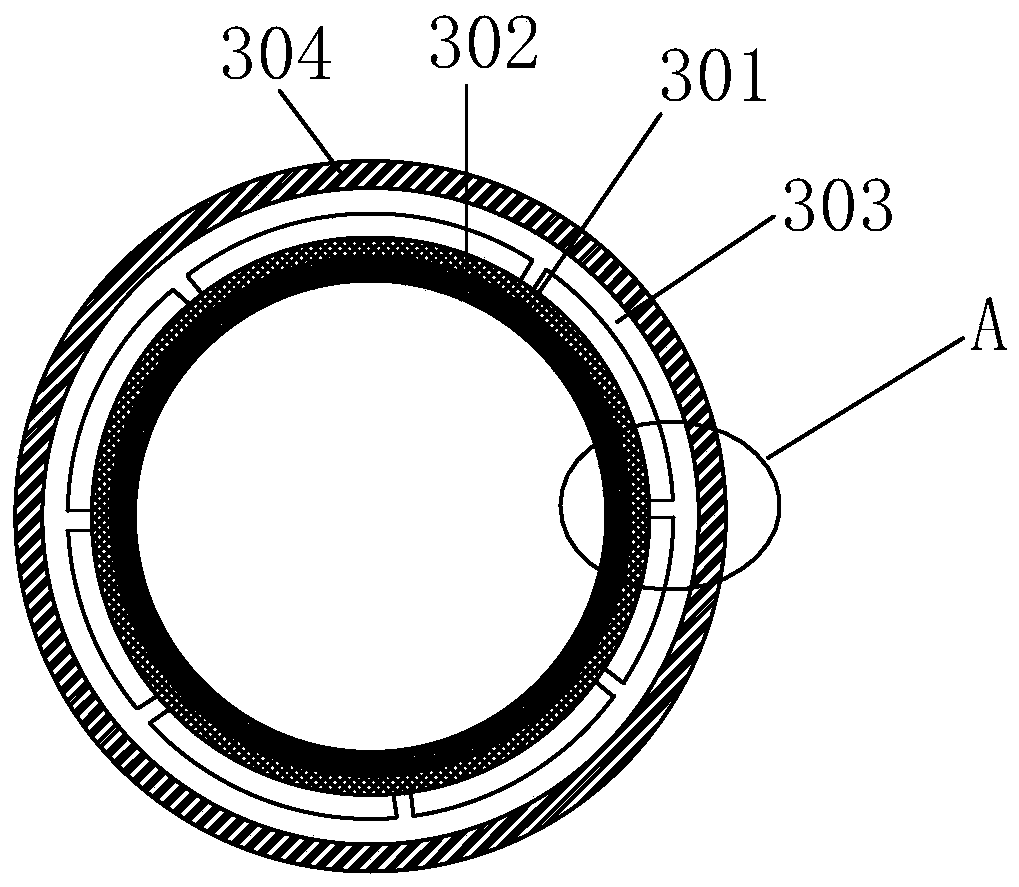

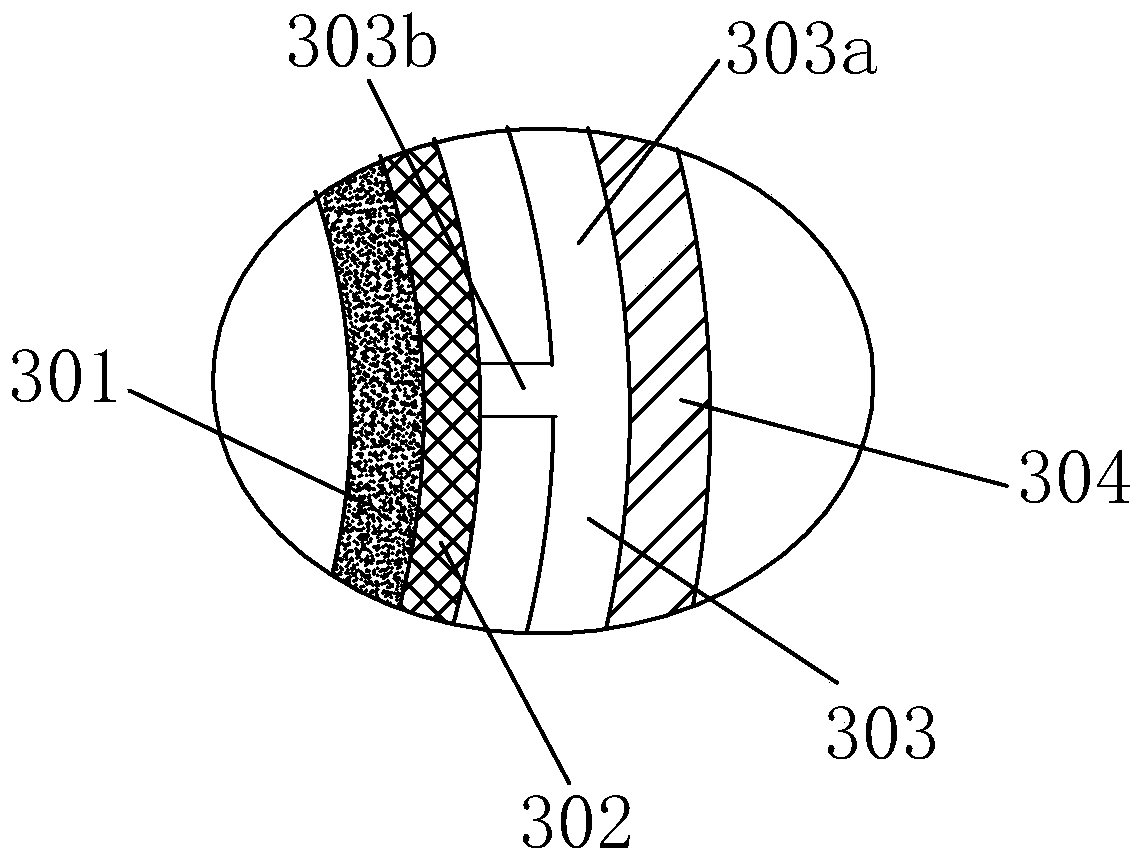

Heat preservation tee pipeline

InactiveCN110864175AGood mechanical propertiesHigh tensile and impact strengthThermal insulationSynthetic resin layered productsHeat conservationEngineering

The invention relates to the technical field of pipelines, and discloses a heat preservation tee pipeline. The heat preservation tee pipeline includes a main pipeline and branch pipelines integrally connected to the side wall of the main pipeline, the main pipeline and the branch pipelines are in communication, the two ends of the main pipeline are each provided with a main connecting portion, thefree ends of the branch pipelines are each provided with a sub-connecting part, and the main pipe and the branch pipelines each comprise a cylindrical conveying layer, a heat preservation layer, a heat insulating layer and a metal layer in sequence from inside to outside. By means of the heat preservation tee pipeline, an externally-assembled heat insulation sleeve is not needed, time and labor are saved, and the good heat preservation effect is achieved; and the conveying layers are made of heat-resistant polyvinyl chloride, the excellent mechanical properties and compactness are achieved, and it can be ensured that leakage or penetration of transported materials is avoided.

Owner:宋晓明

Electrolyte for accumulator without maintenance

InactiveCN101281981AQuality improvementHigh purityLead-acid accumulatorsROSIN POWDERTerminal voltage

The invention relates to an accumulator non-maintenance electrolyte which belongs to field of lead-acid accumulator. The accumulator non-maintenance electrolyte comprises by volume percent: 0.1-0.3 of magnesium carbonate, 3-5 of rosin powder, 0.2-0.3 of humic acid, 0.3-0.4 of potassium permanganate, 2-3 of protanetrione, and the balance of dilute sulfuric acid with specific gravity of 1.27. Advantages of the accumulator non-maintenance electrolyte are that: generation of sulfated pole plate and abscission of pole plate active material are avoided, transition of complex particles are generated, evacuation is magnified, liquid surface tension and adhesive force is increased, reaction speed of ions is quickened, terminal voltage and starting current of accumulator are increased, the electrolyte is not easy to ice in winter and volatilize in summer, quality and purity of electrolyte are greatly increased.

Owner:高日升

Heptamethine hydroxyl indocyanine dye, synthesis method and application thereof

PendingCN111662566AWith near-infrared light absorptionWith fluorescence imagingMethine/polymethine dyesOrganic chemistryCycloalkeneFluorescence

The invention discloses a heptamethine hydroxyl indocyanine dye, a synthesis method and application thereof, and belongs to the field of polymethine indocyanine dyes and preparation thereof, wherein the structural formula of the heptamethine hydroxyl indocyanine dye is represented by a formula (I), and the dye has near-infrared light absorption and fluorescence development performances and can beused as a probe auxiliary agent. The preparation method of the dye comprises the following steps: 1) carrying out a heating reaction on raw materials containing a 2,3,3-trimethyl-hydroxyindole derivative and a nucleophilic substituted compound under a vacuum condition to obtain an organic ammonium salt; and 2) carrying out a heating reaction on a solution containing the organic ammonium salt obtained in the step (1) and a cycloalkene derivative under a closed condition. The method has the advantages of short synthesis route, environment-friendly solvent, simple process, avoidance of noble metal catalysis, high yield, high purity and the like, is high in applicability, and can be used for synthesizing products of various structure types.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-durability metal foam-supported catalyst for steam carbon dioxide reforming and method for preparing the same

Disclosed is a catalyst support for steam carbon dioxide reforming reaction utilizing the advantages of superior thermal conductivity and thermal dispersion of a metal foam support and a large specific surface area of a carrier material, which allows selective control of coating amount and the thickness of a support layer and prevents cracking on the support surface, using both the sol-gel method and the slurry method that have been used for coating of a metal foam support.

Owner:KOREA INST OF SCI & TECH

Production system and method of 1, 2-cyclohexanediamine

PendingCN113248389AReduce manufacturing costAvoid by-productsAmino compound purification/separationOrganic compound preparationProcess engineeringEnvironmental geology

A production system of 1, 2-cyclohexanediamine comprises a solid-liquid separation device, a dehydrating tower, a decoking tower and a refining tower. A material inlet of the solid-liquid separation device is used for being connected with a mixed material source which is discharged by a reactor and subjected to gas-liquid separation, catalyst filtration and dealcoholization. The solid-liquid separation device supplies materials to the dehydrating tower through an overflow pipe. A tower bottom discharge hole of the dehydrating tower supplies materials to the decoking tower through a first pipeline. A tower top discharge hole of the decoking tower supplies materials to the refining tower through a second pipeline. A tower top discharge hole of the refining tower is connected with a return pipeline through a condenser. A return tank, a discharge pump and a first valve are sequentially arranged on the return pipeline. The downstream end of the return pipeline is connected with a return port of the refining tower, a discharge pipe is connected to the return pipeline and located between the discharge pump and the first valve, and a second valve is arranged on the discharge pipe. The system is simple in structure and convenient to operate, can continuously and stably produce 1, 2-cyclohexanediamine products, and meets the actual requirements of chemical enterprises.

Owner:CHONGQING HUAFON CHEM +2

Heptamethane sulfonic indocyanine dye, preparation method and application thereof

InactiveCN111662564AWith near-infrared light absorptionWith fluorescence imagingMethine/polymethine dyesOrganic chemistryCycloalkeneFluorescence

The invention discloses a heptamethine sulfonic indocyanine dye, a preparation method and application thereof, and belongs to the field of polymethine indocyanine dyes and preparation thereof, whereinthe structural formula of the heptamethane sulfonic indocyanine dye is represented by a formula (I), and the dye has near-infrared light absorption and fluorescence development performance and can beapplied to probe aids. The preparation method of the dye comprises the following steps: 1) carrying out a heating reaction on raw materials containing a 2,3,3-trimethyl-sulfonic indole derivative anda nucleophilic substituted compound under a vacuum condition to obtain an organic ammonium salt; and 2) carrying out a heating reaction on a solution containing the organic ammonium salt obtained inthe step (1) and a cycloalkene derivative under a closed condition. The method has the advantages of short synthesis route, environment-friendly solvent, simple process, avoidance of noble metal catalysis, high yield, high purity and the like, is high in applicability, and can be used for synthesizing products of various structure types.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

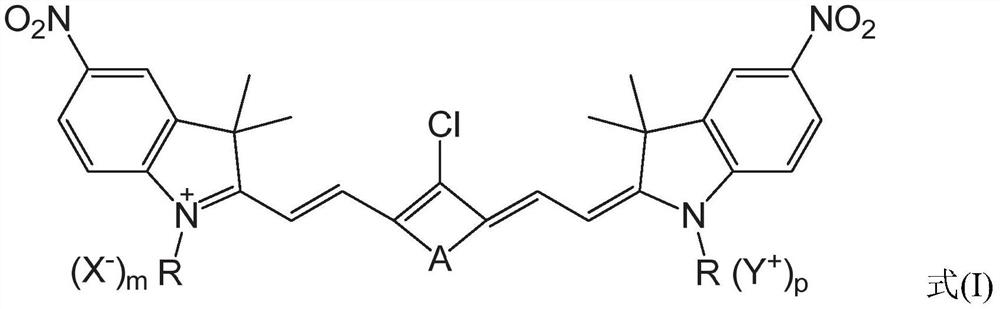

Heptamethine nitroindole cyanine dye, preparation method and application thereof

ActiveCN111662565AWith near-infrared light absorptionWith fluorescence imagingOrganic chemistryMethine/polymethine dyesCyanineNear infrared light

The invention discloses a heptamethine nitro indocyanine dye, a preparation method and application thereof, and belongs to the field of polymethine indocyanine dyes and preparation thereof, wherein the structural formula of the heptamethine nitro indocyanine dye is represented by a formula (I). The preparation method comprises the following steps: 1) carrying out a heating reaction on raw materials containing a 2,3,3-trimethyl-nitroindole derivative and a nucleophilic substituted compound under a vacuum condition to obtain an organic ammonium salt; and 2) carrying out a heating reaction on a solution containing the organic ammonium salt obtained in the step 1) and a cycloalkene derivative under a closed condition. The dye has near-infrared light absorption and fluorescence development properties, and can be used as a probe auxiliary agent; and the preparation method has the advantages of short synthesis route, environment-friendly solvent, simple process, avoidance of noble metal catalysis, high yield, high purity and the like, is high in applicability, and can be used for synthesizing products of various structure types.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of method that uses graphene oxide as an initiator to initiate the polymerization of epoxy monomers

The invention discloses a method for initiating polymerization of an epoxy monomer by using graphene oxide as an initiator. The method comprises the following steps: the epoxy monomer and the graphene oxide are added to a reaction system, wherein, the mass rate of the epoxy monomer to the graphene oxide is 300-5, the graphene oxide can prompt the epoxy monomer to undergo cationic ring-opening polymerization at the temperature of 0-100 DEG C, and the obtained epoxy polymer can be grafted in situ on the surface of a graphene oxide sheet layer, so that surface modification of the graphene oxide is realized, and cation-initiated polymerization and grafting amount are controlled by reaction time and reaction temperature.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Repairing type lubricant additive and its preparation method

The present invention discloses a repairing type lubricating oil additive and its preparation method. Its composition includes 1-10% of aluminium, titanium, zinc and tin granules whose grain size is 10-200 nm, their weight ratio of 5.5-6.5:1.5-2.5:0.5-1.5:0.5-1.5, 88-98% of basis oil for finished product lubricating oil and 1-2% of dispersing additive. Its preparation method incldues the following steps: placing the above-mentioned all the materials into same container, mechanically-stirring and mixing for 20-40 min., placing the mixture and said container into an ultrasonic oscillator to make ultrasonic oscillation for 20-40 min. so as to obtain the invented lubricating oil additive with good repairing effects.

Owner:TIANJIN UNIV

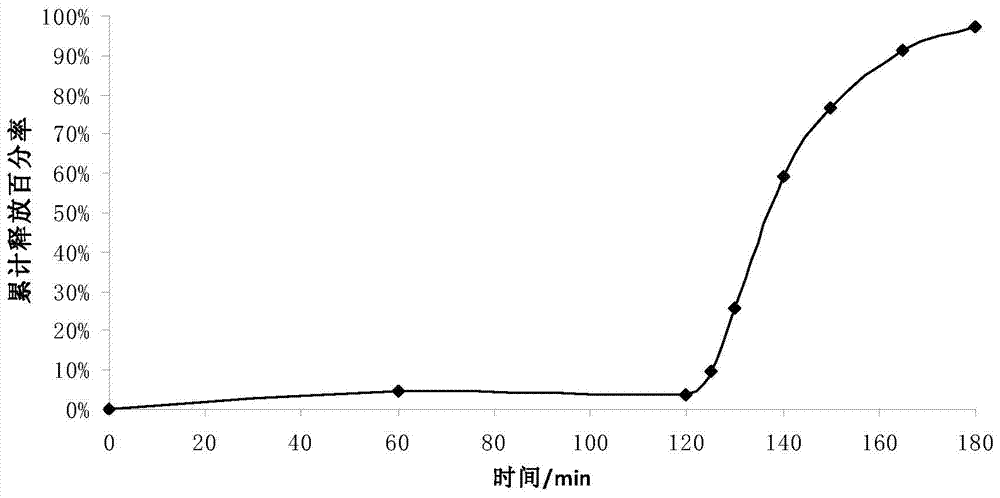

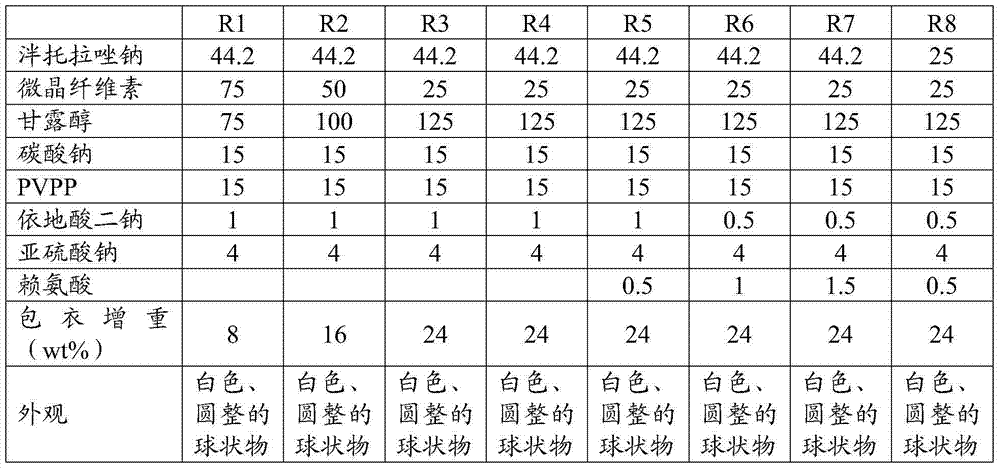

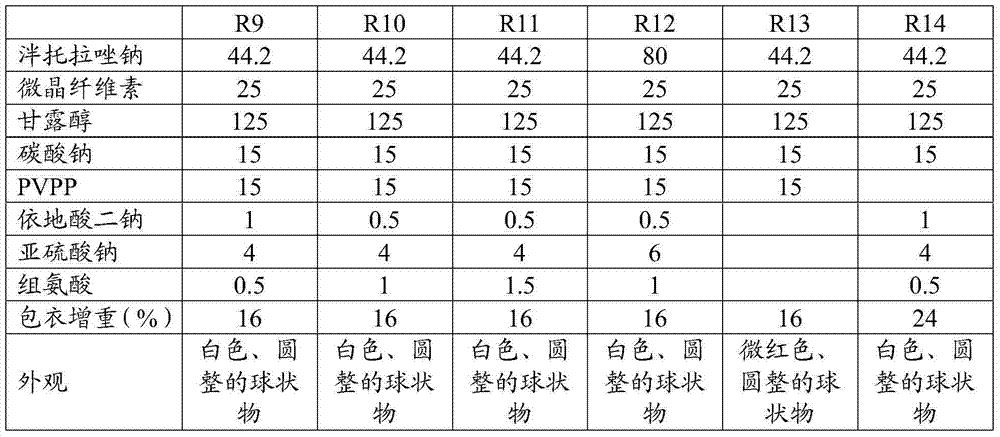

Pantoprazole sodium medicinal composition, pellet containing composition and preparation method of pellet

ActiveCN103800326BImprove structural stabilityImprove stabilityOrganic active ingredientsDigestive systemMedicineAntioxidant

The invention provides a stable pantoprazole sodium medicinal composition. The composition comprises the following components in parts by weight: 10 parts of pantoprazole sodium, 0.05-0.6 part of basic amino acid, 0.5-2.0 parts of antioxidant, 0.05-0.6 part of chelating agent, and 1.2-8.0 parts of pH regulating agent. The invention also provides a preparation containing the medicinal composition, a pellet containing the medicinal composition, a preparation containing the pellet and a preparation method of the pellet. According to the medicinal composition, the stability of pantoprazole sodium can be remarkably improved in the preparing process and the storing process.

Owner:ZHEJIANG UNIV +1

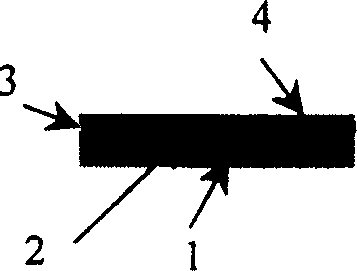

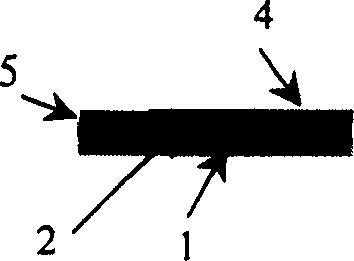

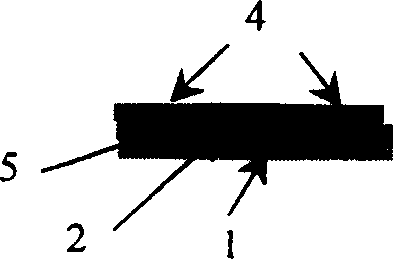

Field emission cathode with confluence electrode

InactiveCN1272821CLower impedanceAvoid catalysisDischarge tube/lamp detailsCooking & bakingScreen printing

The invention is a kind of field transmitting negative electrode which has an affluxion electrode. The invention is a structure for carbon nano pipe field transmitting negative electrode manufactured with screen printing method, the structure can reduces the resistance of the electrode, and upgrades the uniformity of the negative potential. It includes a transparent conductive electrode on the glass base, an affluxion electrode and the negative electrode on the transparent conductive electrode, the affluxion electrode is narrower than the transparent conductive electrode. The negative and the affluxion electrode are arranged on the transparent conductive electrode, the affluxion electrode also can be set at one side of the negative electrode or in the middle of the negative electrode. The negative electrode 4 also can be produced on the transparent conductive electrode and covers on the affluxion electrode. The technology can reduce the electrode resistance, avoids the catalyst effect to the negative electrode oxidization caused by the electrode broken circuit and the metal in the process of baking, and upgrades the reliability of the device.

Owner:SOUTHEAST UNIV

Method for synthesizing ultrahigh-viscosity water-soluble block polyether by one-pot method

The invention relates to a method for synthesizing ultrahigh-viscosity water-soluble block polyether by a one-pot process, which comprises the following steps: placing a compound containing reactive hydrogen in a reaction kettle, adding a phosphazene catalyst to catalyze nucleophilic substitution reaction between the reactive hydrogen and initial polyether, vacuumizing, and heating to 130-150 DEG C in the reaction kettle; introducing a mixture of ethylene oxide and propylene oxide into the reaction kettle, and carrying out nucleophilic substitution reaction on the mixture and reactive hydrogen to generate polyether polyol; introducing ethylene oxide into the reaction kettle to generate ethylene oxide-terminated polyether polyol; after the reaction is finished, aging until the pressure in the reaction kettle is unchanged; introducing an isocyanate cross-linking agent; reacting the primary hydroxyl group in the ethylene oxide terminated polyether polyol of the primary hydroxyl group to generate macromolecular polyether polyol; and vacuumizing to remove the solvent to obtain the ultrahigh-viscosity water-soluble block polyether. The alkali metal content in the polyether is reduced, the molecular weight of the polyether is improved, and the viscosity of the water-soluble block polyether is increased.

Owner:南京联智科技有限公司

Method for preparing compound calcium and zinc stabilizer for plastic pipeline

The invention relates to the technical field of stabilizers for plastic pipelines, and discloses a method for preparing a compound calcium and zinc stabilizer for a plastic pipeline. The method comprises the following steps that (1) the raw materials are weighed and taken in parts by weight: 15 to 30 parts of calcium stearate, 15 to 30 parts of zinc stearate, 10 to 15 parts of modified montmorillonite, 3 to 5 parts of a butyl stearate lubricant, 0.5 to 1 part of an antioxidant, and 0.5 to 1 part of an ultraviolet light absorber; (2) the calcium stearate, the zinc stearate, and butyl stearate are added into a homogenizer to be uniformly stirred at 50 to 60 DEG C to obtain a premix; and (3) the modified montmorillonite, the antioxidant, and the ultraviolet light absorber are added into the premix to be uniformly stirred at 45 to 50 DEG C, and the compound calcium and zinc stabilizer is obtained. The prepared compound calcium and zinc stabilizer is environmentally friendly, and the heat resistance performance of a polyvinyl chloride pipeline can be significantly improved.

Owner:刘琴

Iron removing process for flax roving

The invention relates to an iron removing process for flax roving and belongs to the technical field of flax processing. The iron removing process includes: iron ion removing is performed on the flax roving to remove iron ions in hemp fibers, then normal degumming and bleaching are performed on the roving, and finally the roving is washed. The iron removing process has the advantages that the iron removing is performed before the oxygen bleaching, hydrogen peroxide is prevented from being catalyzed by iron, the strength of the roving is increased effectively, the reaction during the oxygen bleaching is stable and even, and damage to fibers is small.

Owner:浙江金达亚麻有限公司

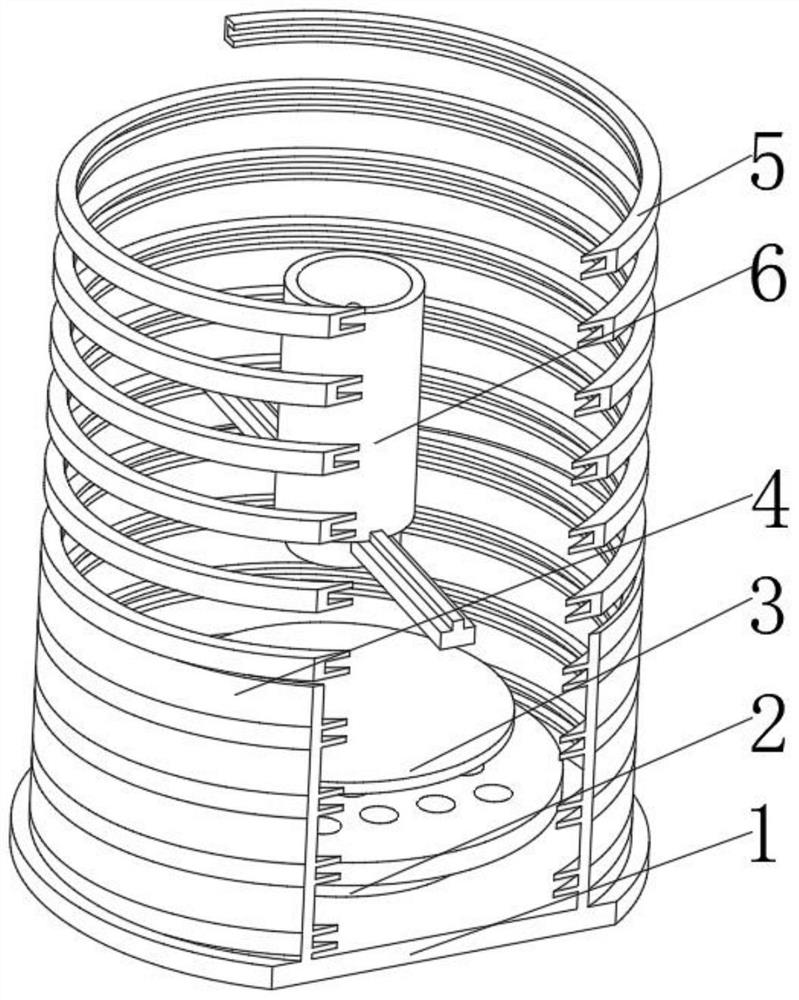

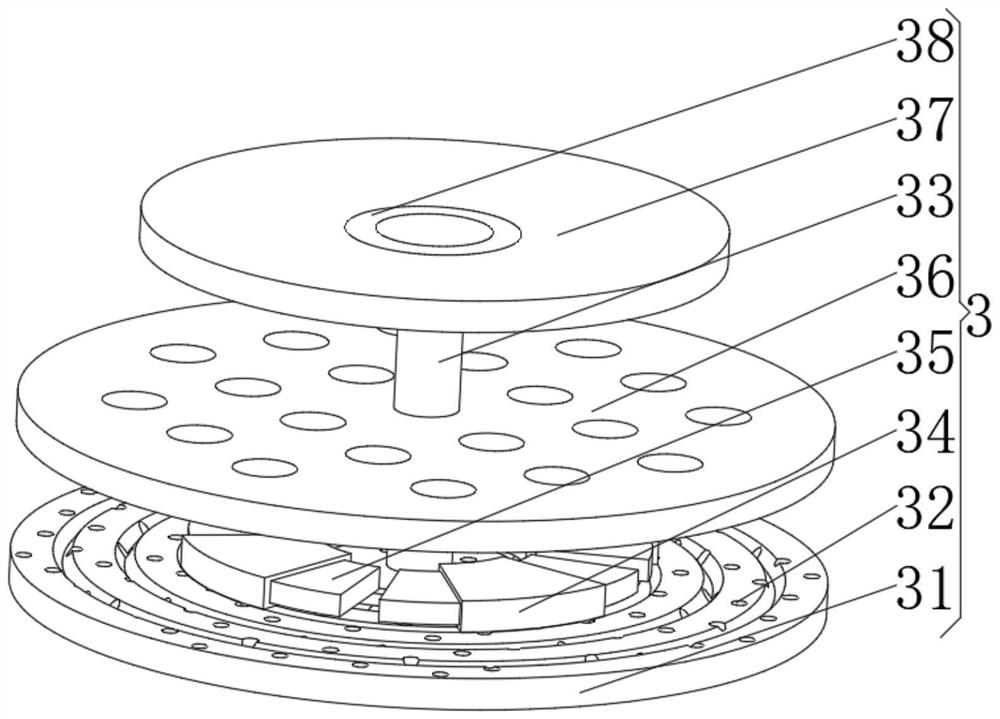

Flexible additive manufacturing equipment

InactiveCN113619109AAvoid damageAvoid catalysisAdditive manufacturing apparatus3D object support structuresPhysicsInjection air

The invention discloses flexible additive manufacturing equipment. The flexible additive manufacturing equipment specifically comprises a base plate, an air injection fan, a manufacturing carrying table, a spiral rail and a manufacturing device, wherein the air injection fan is mounted at the top of a circular plate body, the manufacturing carrying table is mounted at the top of the air injection fan, the spiral rail is mounted on the inner surface of an air ring plate, and the manufacturing device is mounted on the inner surface of the spiral rail; and the manufacturing carrying table comprises a threaded disc, an auxiliary rotating shaft,a wind shielding plate, telescopic elastic plates and a breathable carrying disc, wherein the auxiliary rotating shaft is mounted in the middle of the top of the disc body, the wind shielding plate is mounted at the top of the disc body, the telescopic elastic plates are mounted on the two sides of the wind shielding plate, and the breathable carrying disc is mounted at the top of the auxiliary rotating shaft. The invention relates to the technical field of robot transportation equipment. Through the design of the air injection fan and the spiral rail, air flow is circularly gathered, and members for additive manufacturing are rapidly cooled in a concentrated mode, so that it is ensured that the members are rapidly hardened, the members are prevented from being excessively accumulated due to softening in the temperature process of the members, and the members are prevented from being damaged.

Owner:鲁康权

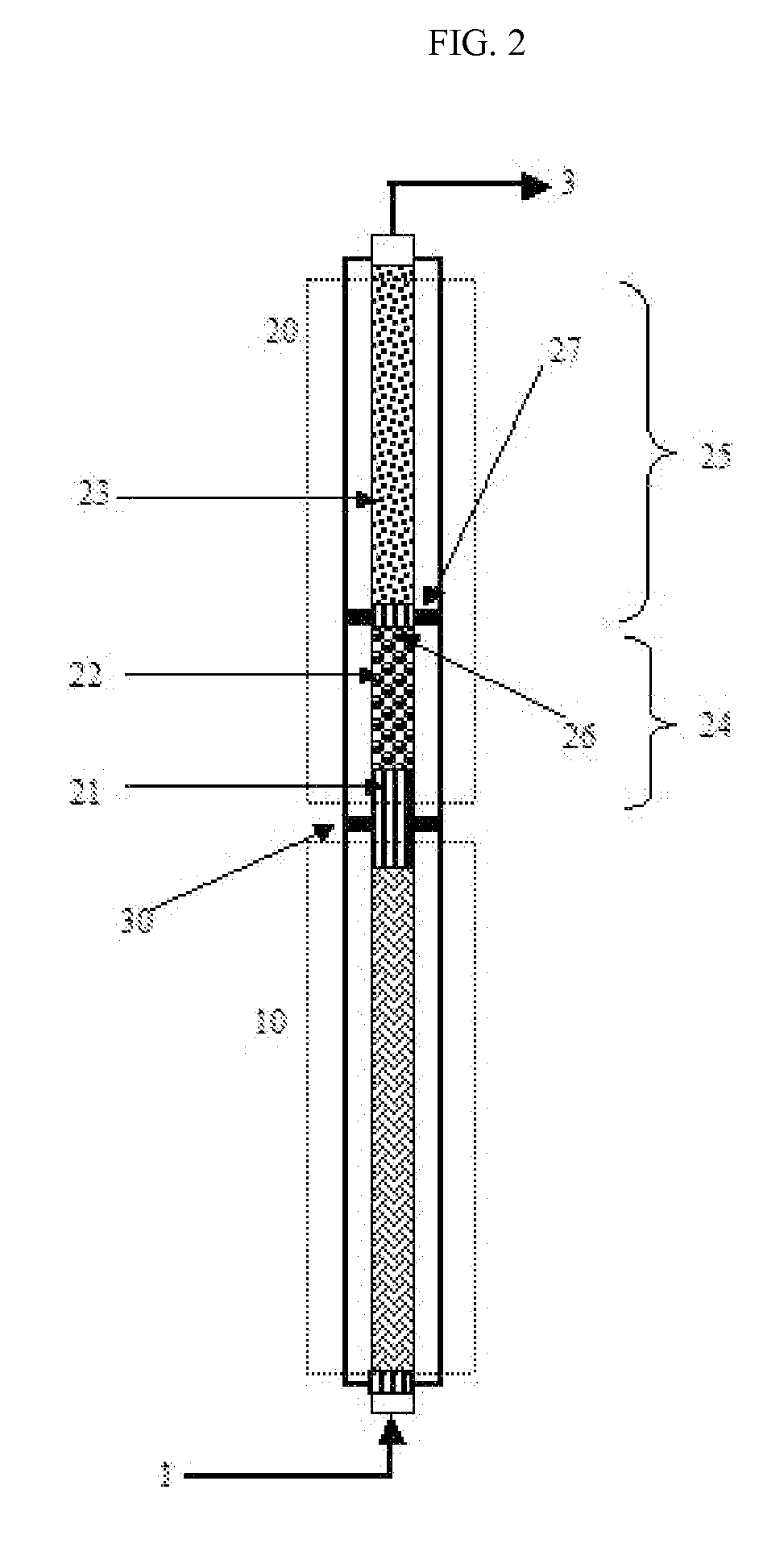

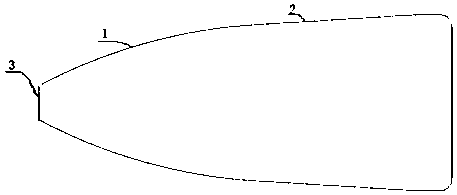

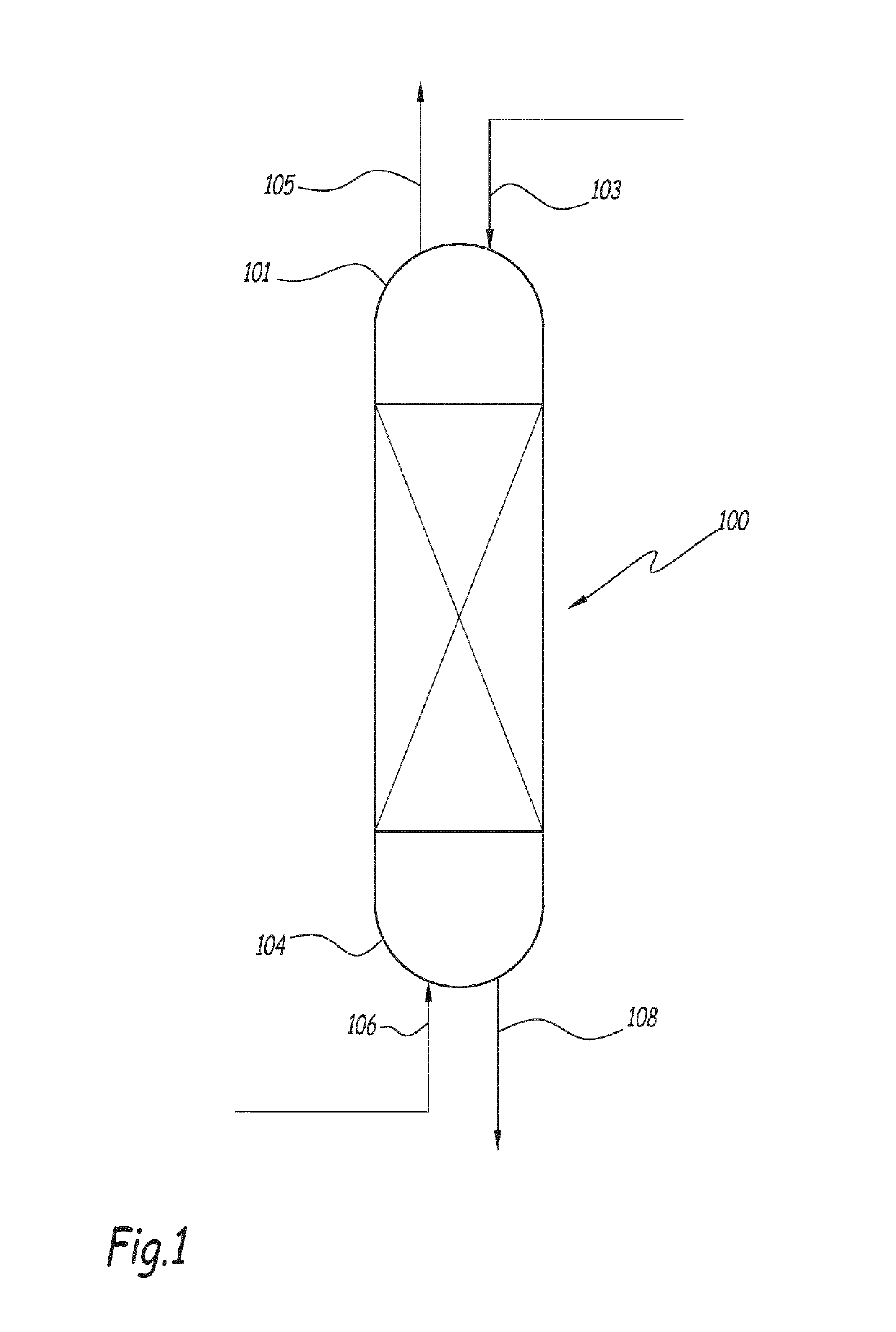

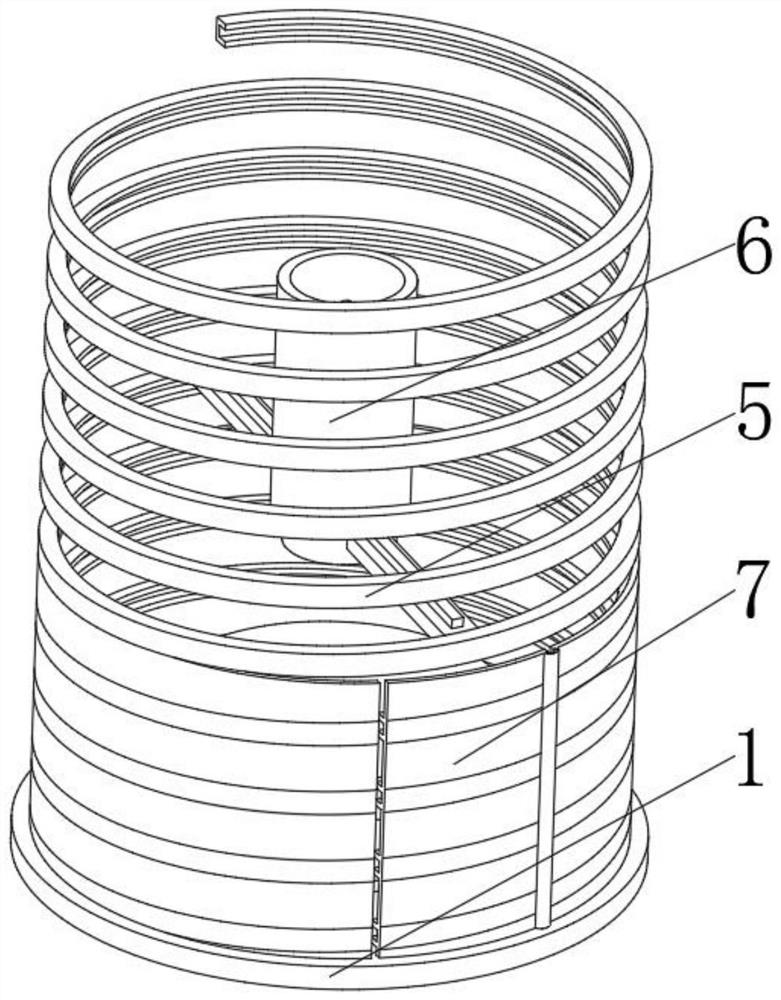

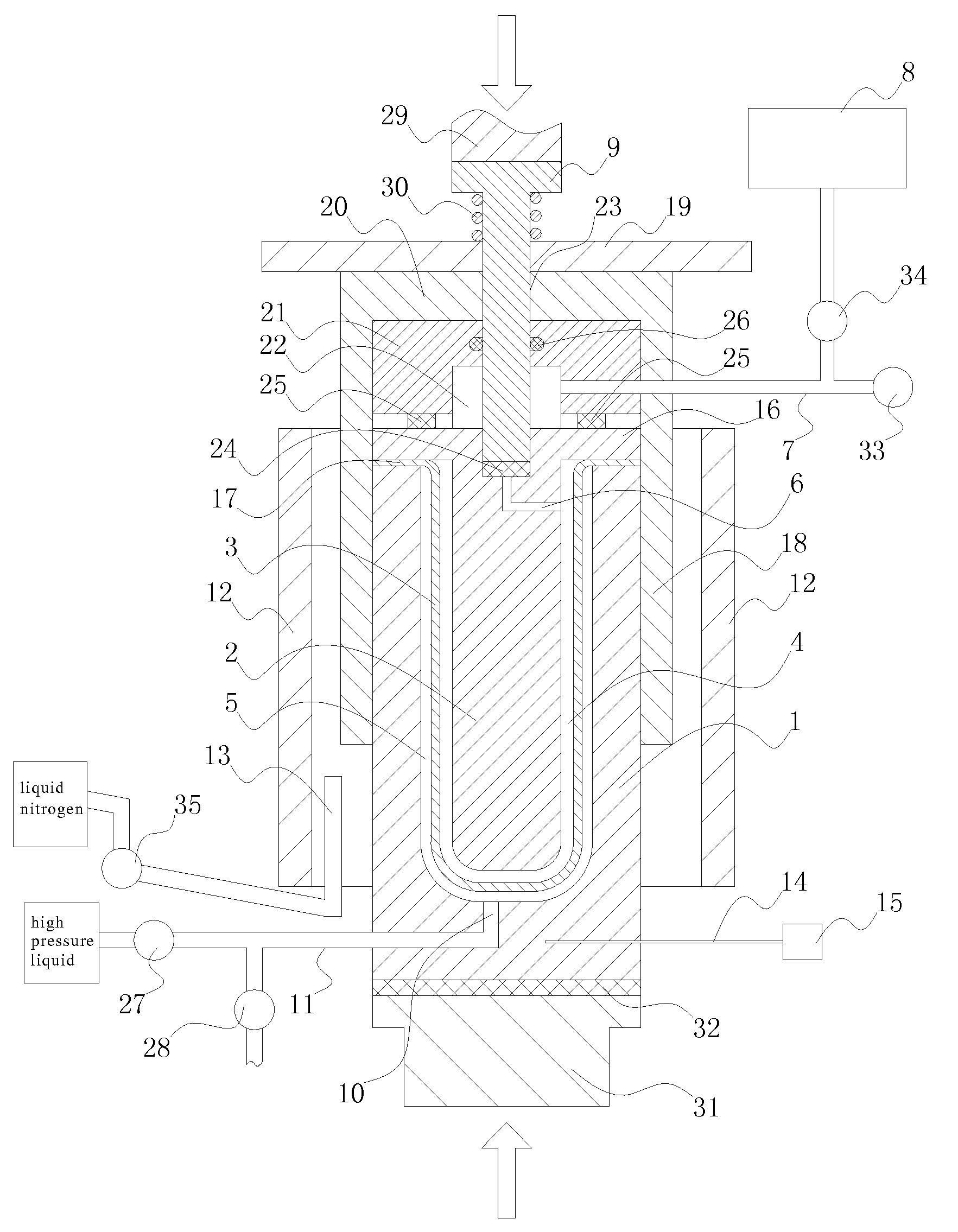

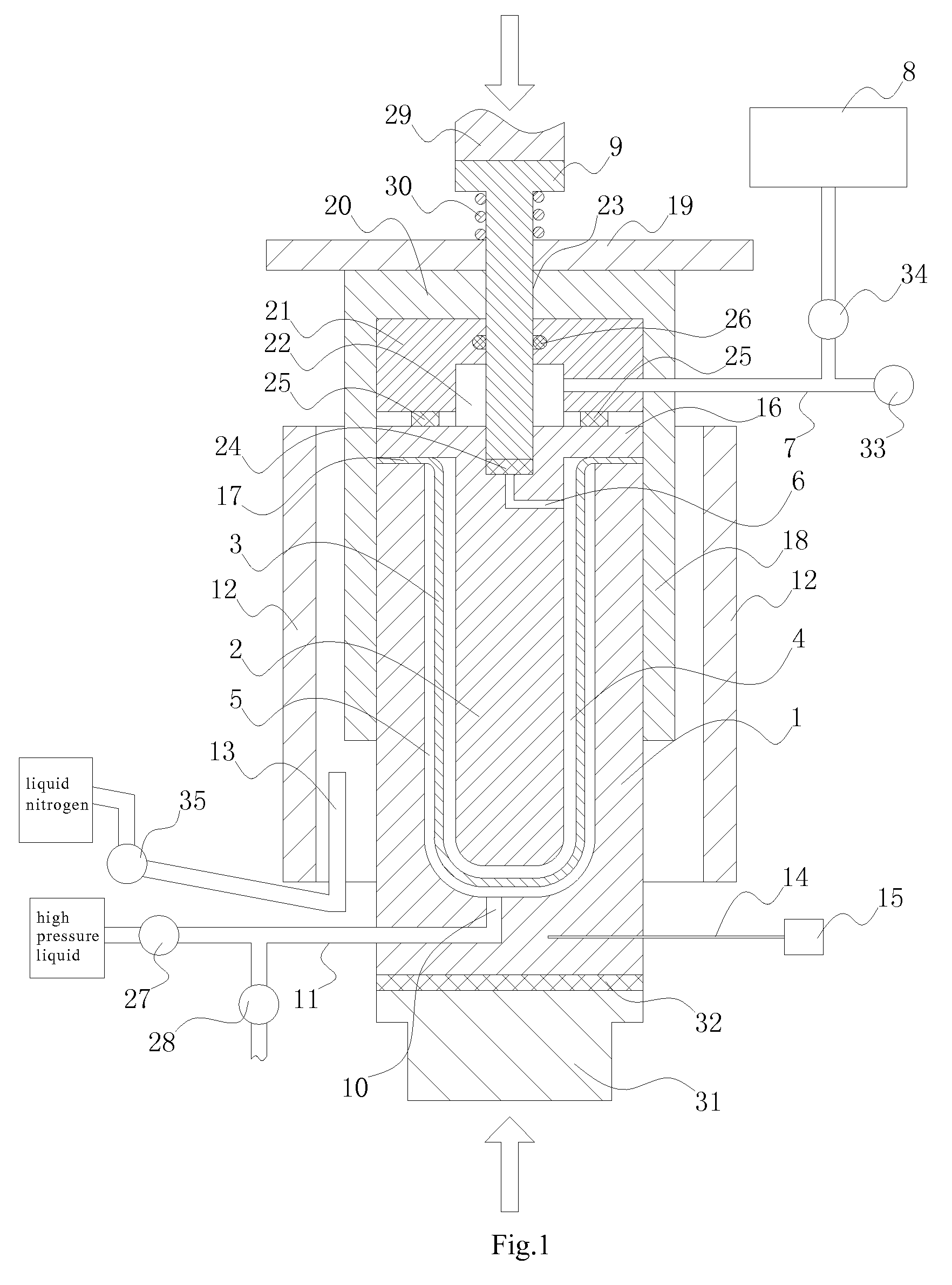

Intermittently opened cracking crude oil apparatus

InactiveUS7955571B2Avoid catalysisLow costThermal non-catalytic crackingPressurized chemical processTemperature controlEngineering

The present invention discloses an intermittently opened cracking crude oil apparatus comprising a high pressure container (1), a support post (2) and a gold sleeve (3). A sealed reaction chamber of natural gas (4) is formed between an exterior surface of the support post and an interior surface of the gold sleeve, and a sealed high pressure chamber (5) is formed between an interior surface of the high pressure container and an exterior surface of the gold sleeve. A gas outlet is provided in the support post and communicates the reaction chamber of natural gas, the gas outlet communicating a gas conduit (7), the gas conduit being connected to a natural gas collector (8). A movable valve needle (9) is provided on the gas outlet to control open and close of the gas outlet. A liquid inlet (10) is provided on the high pressure container and communicates the high pressure chamber, the liquid inlet communicating a liquid conduit (11) which communicates a high pressure liquid supply. A heater (12) and a nozzle of liquid nitrogen (13) are provided outside the high pressure container. A thermocouple (14) is provided on the high pressure container, the thermocouple being connected to a temperature control (15) which can control operating conditions of the heater and the nozzle of liquid nitrogen.

Owner:CHINA ACAD OF SCI GUANGZHOU EARTH CHEM RES INST

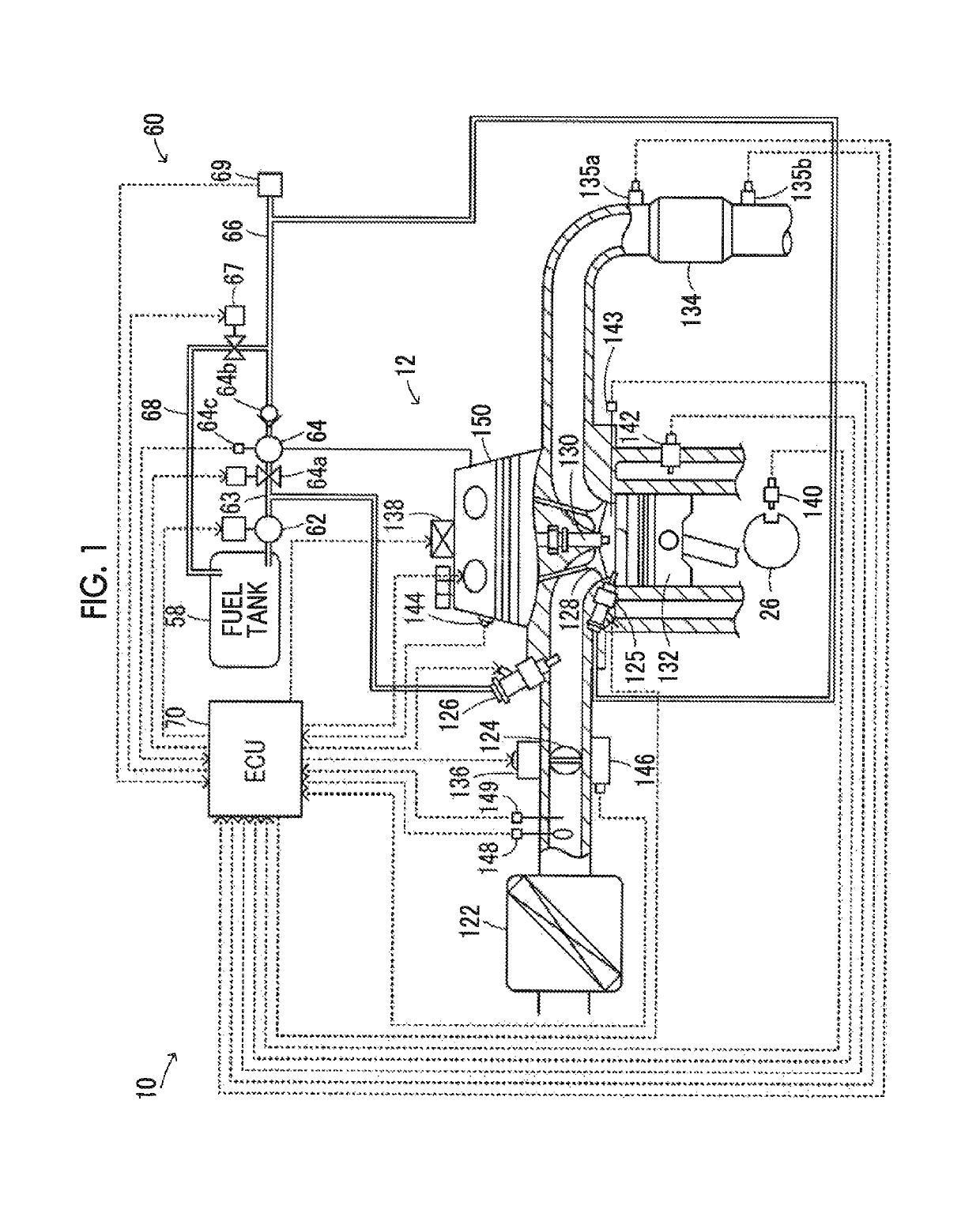

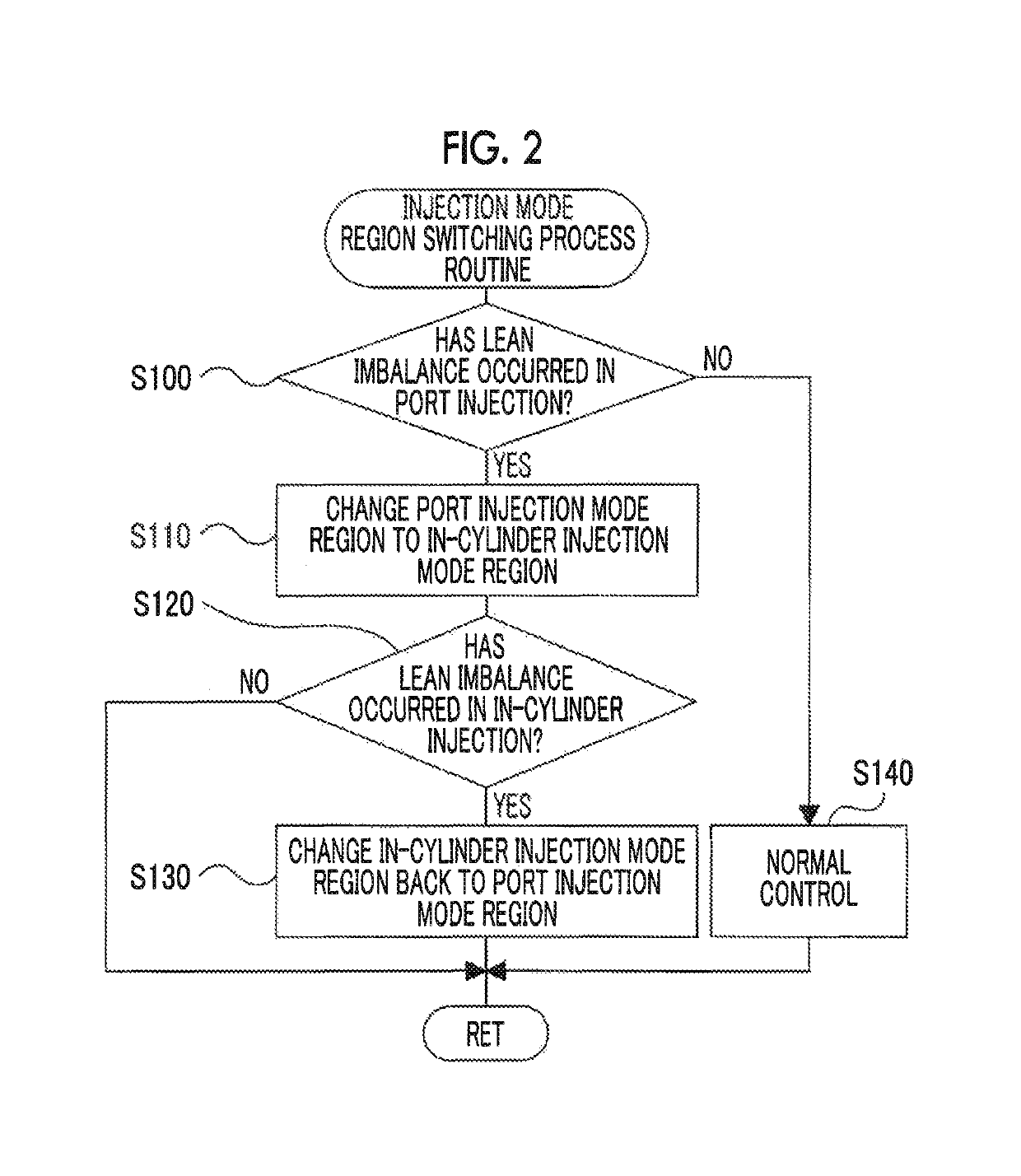

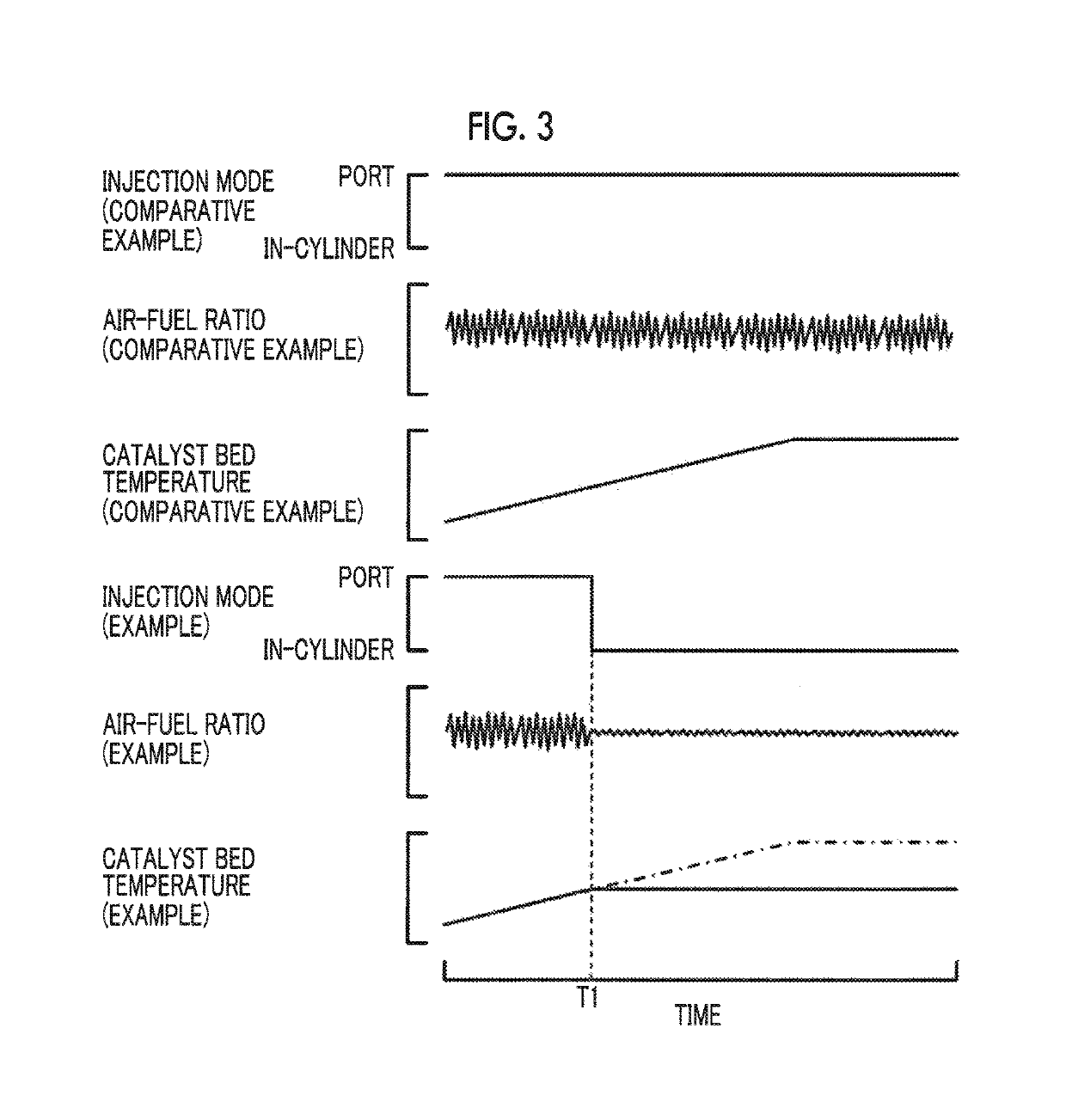

Engine system and control method for engine system

InactiveUS10344701B2Inhibition imbalanceAvoid overall overheatingElectrical controlMachines/enginesFuel supplyFuel injection

An engine system includes an engine that, a fuel supply device, and an electronic control unit. The electronic control unit is configured to control the fuel supply device and to perform operation control of the engine by adjusting an injection ratio between fuel injection from an in-cylinder injection valve and a port injection valve according to the operation state of the engine. The electronic control unit is configured to perform imbalance determination. The electronic control unit is configured to change a region of fuel injection from a first fuel injection region to a second fuel injection region when the electronic control unit determines that a lean imbalance is occurred with respect to the fuel injection in which the fuel injection from the port injection valve is performed.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com