Method for preparing compound calcium and zinc stabilizer for plastic pipeline

A technology of composite calcium-zinc and plastic pipes, which is applied in the field of plastic pipe stabilizers, can solve the problems of organic tin stabilizers such as high price and non-environmental protection, and achieve the effects of improving utilization rate, improving dispersion performance and strong adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

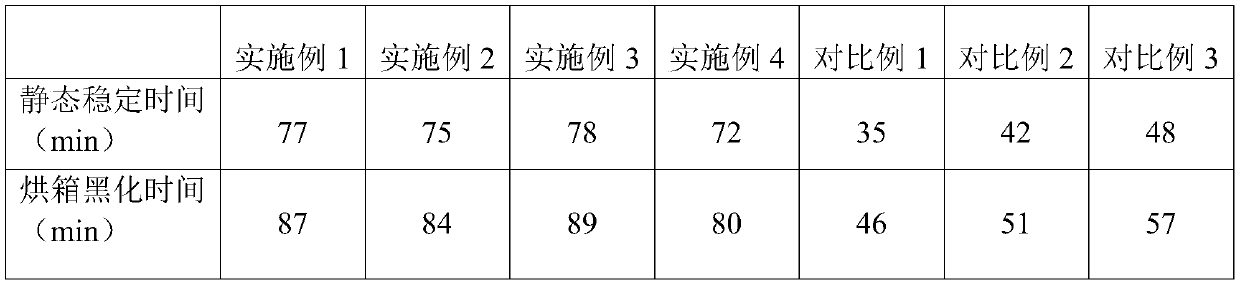

Examples

Embodiment 1

[0025] The preparation method of amino quaternary ammonium salt comprises the following steps:

[0026] Adding hyperbranched polyethyleneimine to a mass concentration of 50% ethanol aqueous solution, stirring and dissolving to obtain a concentration of 5wt% hyperbranched polyethyleneimine solution, adding epichlorohydrin to the hyperbranched polyethyleneimine solution, hyperbranched polyethyleneimine The mass ratio of ethyleneimine to epichlorohydrin is 1:0.3, heated to 48°C in a water bath, condensed and refluxed for 4 hours under stirring conditions, concentrated by rotary evaporation to remove the aqueous ethanol solution, transferred to an oven and dried at 55°C for 2 hours to obtain Intermediate product, intermediate product and dimethylethanolamine were added to deionized water, the mass ratio of intermediate product to dimethylethanolamine was 1:0.2, the mass volume ratio of intermediate product to deionized water was 1g / 80mL, and the water bath was heated to 56 ℃, heat...

Embodiment 2

[0034] The preparation method of amino quaternary ammonium salt comprises the following steps:

[0035] Adding hyperbranched polyethyleneimine to a mass concentration of 50% ethanol aqueous solution, stirring and dissolving to obtain a concentration of 5wt% hyperbranched polyethyleneimine solution, adding epichlorohydrin to the hyperbranched polyethyleneimine solution, hyperbranched polyethyleneimine The mass ratio of ethyleneimine to epichlorohydrin is 1:0.1, heated to 48°C in a water bath, condensed and refluxed for 4 hours under stirring conditions, concentrated by rotary evaporation to remove the aqueous ethanol solution, transferred to an oven and dried at 55°C for 2 hours to obtain Intermediate product, intermediate product and dimethylethanolamine were added to deionized water, the mass ratio of intermediate product to dimethylethanolamine was 1:0.4, the mass volume ratio of intermediate product to deionized water was 1g / 80mL, and the water bath was heated to 56 ℃, heat...

Embodiment 3

[0043] The preparation method of amino quaternary ammonium salt comprises the following steps:

[0044] Adding hyperbranched polyethyleneimine to a mass concentration of 50% ethanol aqueous solution, stirring and dissolving to obtain a concentration of 5wt% hyperbranched polyethyleneimine solution, adding epichlorohydrin to the hyperbranched polyethyleneimine solution, hyperbranched polyethyleneimine The mass ratio of ethyleneimine to epichlorohydrin is 1:0.2, heated to 50°C in a water bath, condensed and refluxed for 5 hours under stirring conditions, concentrated by rotary evaporation to remove the aqueous ethanol solution, transferred to an oven and dried at 55°C for 2 hours to obtain Intermediate product, intermediate product and dimethylethanolamine were added to deionized water, the mass ratio of intermediate product to dimethylethanolamine was 1:0.3, the mass volume ratio of intermediate product to deionized water was 1g / 80mL, and the water bath was heated to 60 ℃, heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com