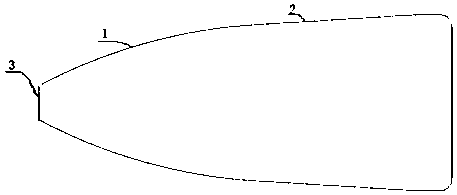

Reinforced seamless steel pipe piercing plug and manufacturing method thereof

A technology for perforated plugs and seamless steel pipes, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of increasing the difficulty of steel pipe manufacturing and processing, uneven pits on the surface of the plug, poor quality of the inner wall of the steel pipe, etc., and achieve high temperature Hardness and resistance to alternating cold and heat, improving high temperature mechanical properties, and improving the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A reinforced seamless steel pipe perforated plug, including a plug base, the outer surface of the plug base is sequentially provided with a transition layer and a reinforcement layer from the inside to the outside, and the transition layer includes the following components in parts by weight:

[0052] Iron: 69.0%;

[0053] Cobalt: 7.0%;

[0054] Chromium: 10.0%.

[0055] Molybdenum: 10.0%;

[0056] Nickel: 4.0%;

[0057] The strengthening layer is composed of two parts: a main material with a mass fraction of 96% and an additive with a mass fraction of 4%, and the additive is made of nickel-coated graphite powder and titanium oxide powder, and the nickel-coated graphite and titanium oxide powder The mass fraction of each is 2%, and the main material includes the following components in parts by weight:

[0058] Cobalt: 25.0%;

[0059] Nickel: 30.0%;

[0060] Chromium: 15.0%;

[0061] Niobium: 5.0%;

[0062] Silicon: 1.5%;

[0063] Tungsten: 2.0%;

[0064] Carb...

Embodiment 2

[0075] A reinforced seamless steel pipe perforated plug, including a plug base, the outer surface of the plug base is sequentially provided with a transition layer and a reinforcement layer from the inside to the outside, and the transition layer includes the following components in parts by weight:

[0076] Iron: 69.5%;

[0077] Cobalt: 7.5%;

[0078] Chromium: 15.0%.

[0079] Molybdenum: 5.0%;

[0080] Nickel: 3.0%;

[0081] The strengthening layer is composed of two parts: a main material with a mass fraction of 96% and an additive with a mass fraction of 4%, and the additive is made of nickel-coated graphite powder and titanium oxide powder, and the nickel-coated graphite and titanium oxide powder The mass fraction of each is 2%, and the main material includes the following components in parts by weight:

[0082] Cobalt: 25.0%;

[0083] Nickel: 25.0%;

[0084] Chromium: 18.0%;

[0085] Niobium: 5.5%;

[0086] Silicon: 1.5%;

[0087] Tungsten: 1.5%;

[0088] Carbo...

Embodiment 3

[0099] Embodiment three differs from embodiment one in that:

[0100] A reinforced seamless steel pipe perforated plug, including a plug base, the outer surface of the plug base is sequentially provided with a transition layer and a reinforcement layer from the inside to the outside, and the transition layer includes the following components in parts by weight:

[0101] Iron: 79.0%;

[0102] Cobalt: 5.0%;

[0103] Chromium: 10.0%.

[0104] Molybdenum: 5.0%;

[0105] Nickel: 1.0%;

[0106] The strengthening layer is composed of two parts: a main material with a mass fraction of 96% and an additive with a mass fraction of 4%, and the additive is made of nickel-coated graphite powder and titanium oxide powder, and the nickel-coated graphite and titanium oxide powder The mass fraction of each is 2%, and the main material includes the following components in parts by weight:

[0107] Cobalt: 30.0%;

[0108] Nickel: 30.0%;

[0109] Chromium: 18.0%;

[0110] Niobium: 5.5%;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com