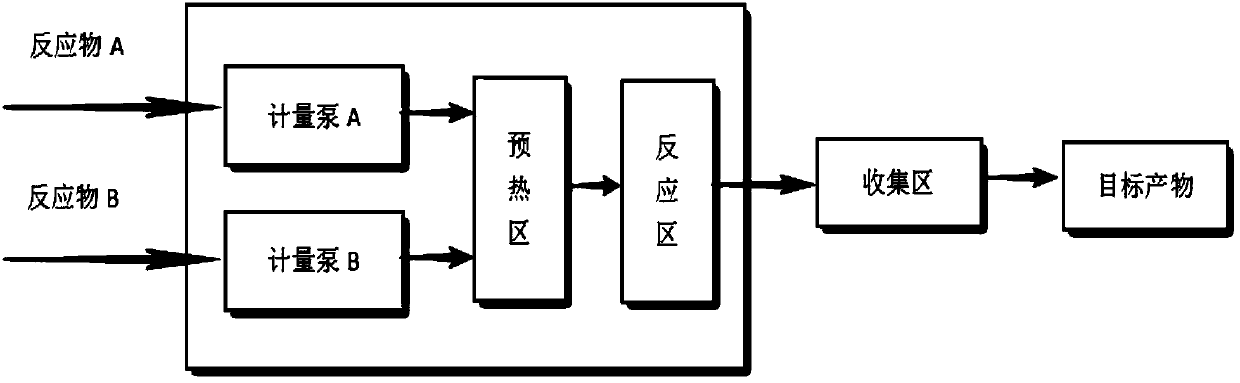

Method for continuously producing methyl acetoacetate by using micro-channel reactor

A micro-channel reactor, methyl acetoacetate technology, applied in organic chemistry, ketene/polyketene preparation and other directions, can solve the problems of easy temperature out of control system, unsuitable for industrial production, long reaction time, etc., to avoid The effect of flying temperature phenomenon, short production cycle and stable reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

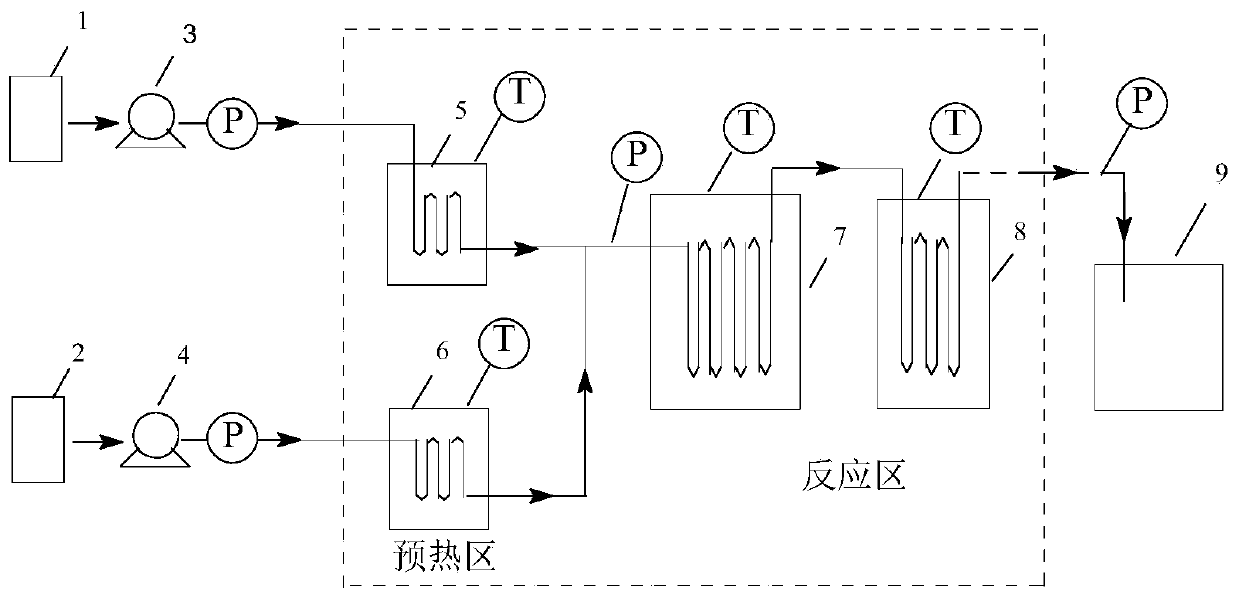

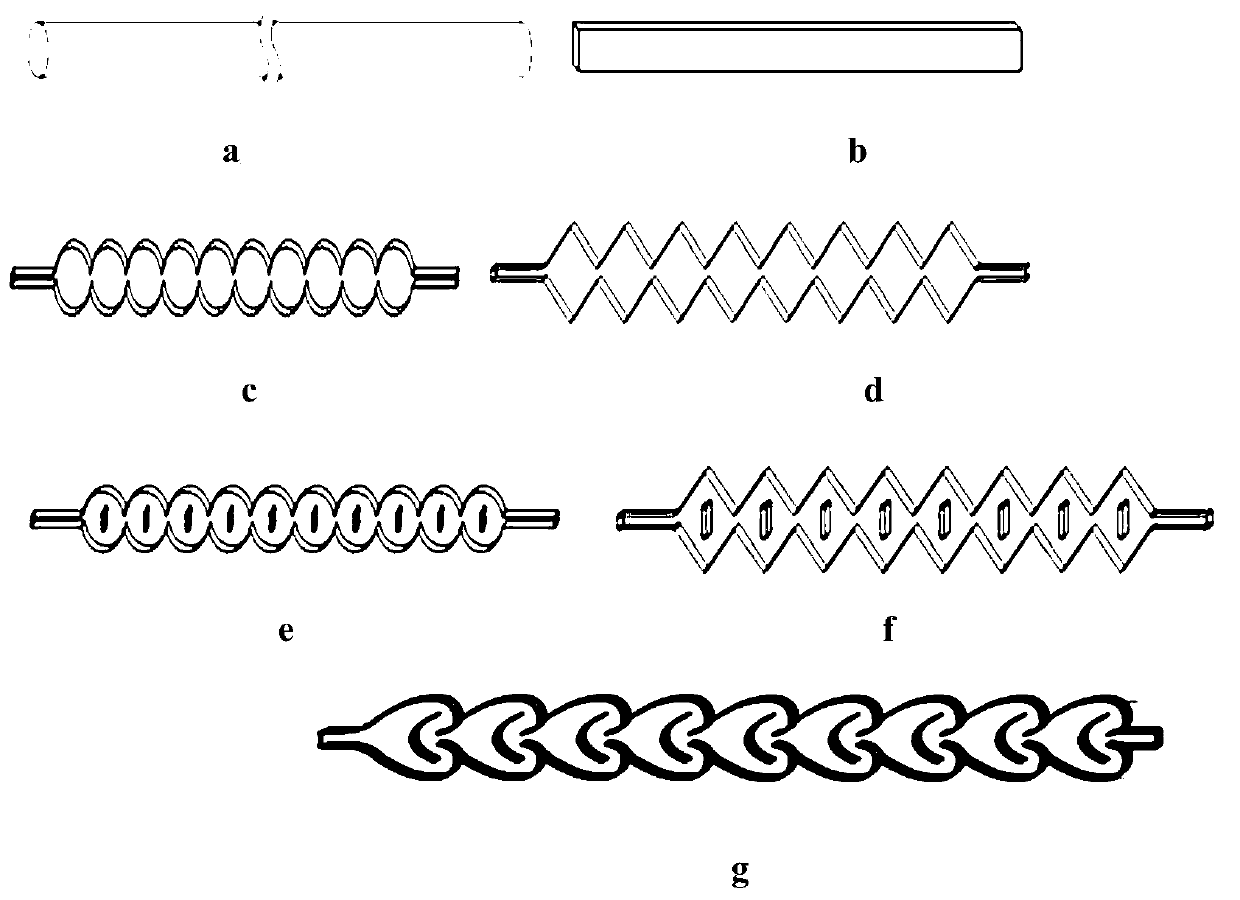

[0028] (1) Device: continuous flow microchannel reaction device (3a+3a), refer to figure 2 Determine the connection mode of the microchannel reactor, the length of the microchannel is determined according to the flow rate and the reaction residence time, and the heat transfer medium is heat transfer oil.

[0029] (2) Preparation of methyl acetoacetate: adjust the microchannel reaction device to be a preheating zone, a reaction zone and a quenching zone according to the needs of the reaction process. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 30s, the preheating temperature and the reaction temperature are set to 70° C., and the reaction pressure is 5 bar. The mixture of substrate methanol and catalyst sulfuric acid is fed into preheating zone A of the device through metering pump 1, and diketene is fed into preheating zone B of the device through pump 2. After the two materials are ...

Embodiment 2

[0031] (1) Device: continuous flow microchannel reaction device (3a+3b), refer to figure 2 Determine the connection mode of the microchannel reactor, the length of the microchannel is determined according to the flow rate and the reaction residence time, and the heat transfer medium is heat transfer oil.

[0032](2) Preparation of methyl acetoacetate: adjust the microchannel reaction device to be a preheating zone, a reaction zone and a quenching zone according to the needs of the reaction process. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 60s, the preheating temperature and the reaction temperature are set to 80° C., and the reaction pressure is 10 bar. The mixture of substrate methanol and catalyst oxalic acid is fed into preheating zone A of the device through metering pump 1, and diketene is fed into preheating zone B of the device through pump 2. After the two streams of mater...

Embodiment 3

[0034] (1) Device: continuous flow microchannel reaction device (3a+3c), refer to figure 2 Determine the connection mode of the microchannel reactor, the length of the microchannel is determined according to the flow rate and the reaction residence time, and the heat transfer medium is heat transfer oil.

[0035] (2) Preparation of methyl acetoacetate: adjust the microchannel reaction device to be a preheating zone, a reaction zone and a quenching zone according to the needs of the reaction process. By adjusting the flow rate of the pump and the channel length of the microchannel, the residence time of the reaction is controlled to be 90s, the preheating temperature and the reaction temperature are set to 90° C., and the reaction pressure is 15 bar. The mixture of substrate methanol and catalyst citric acid is fed into preheating zone A of the device through metering pump 1, and diketene is fed into preheating zone B of the device through pump 2. After the two streams of mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com