Processes for producing 3-amino crotonic acid cinnamyl ester and cilnidipine in large scale

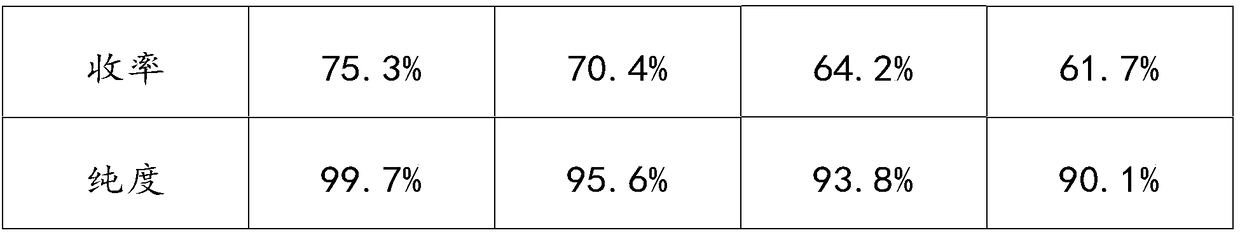

A large-scale, crotonic acid technology, applied in the preparation of ketene/polyketene, the preparation of organic compounds, organic chemistry, etc., to achieve the effect of reducing industrial costs, ensuring yield and purity, and ensuring purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a kind of technique of large-scale production of cinnamyl 3-amino-2-butenoate, comprising the following steps:

[0039] S1, preparing crude cinnamyl acetoacetate;

[0040] 100 kg of cinnamyl alcohol was dropped into a 200L reaction kettle, triethylamine was added, and the temperature was raised. When the temperature in the kettle reached 75° C., a total amount of 68 kg of diketene was added dropwise.

[0041] Take every 10kg of diketene as a dropping unit, and make it drop into the glass high tank at the production site for dropping.

[0042] It is advisable to add 10kg every 40 minutes for the dropping speed, and the dropping temperature shall not exceed 85°C.

[0043] After all the diketene was added dropwise, the reaction was kept at 85° C. for 5 hours.

[0044] After the heat preservation reaction is finished, the content of the produced substance is detected by high-performance liquid phase analysis on-line. The column temperature ...

Embodiment 2-3

[0055] The technique for the large-scale production of 3-amino-2-butenoic acid cinnamyl ester provided by embodiment 2-3 is consistent with the steps of the large-scale production of 3-amino-2-butenoic acid cinnamyl ester provided by embodiment 1, The difference is that the operating conditions change.

Embodiment 2

[0057] The temperature in the reaction kettle was 85° C., the rate of dropping diketene was 10 kg in 30 minutes, and the temperature was kept for 6 hours. The temperature of the amination reaction is 2-8° C., the time of the amination reaction is 36-37 hours, and 25% methanol is used for bleaching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com