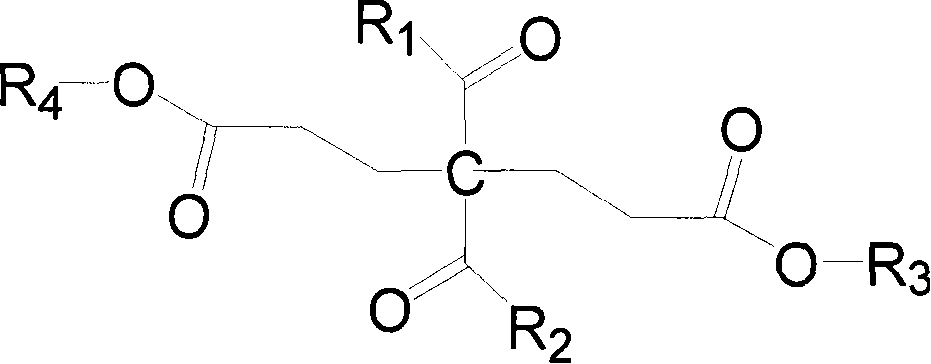

Method for synthesizing same carbon dicarbonyl photosensitive resin

A synthesis method and photosensitive resin technology, which is applied in the preparation of ketene/polyketene, coating, organic chemistry, etc., can solve the problems of loss of application value of photocurable resin, increase in viscosity, etc., and achieve improved storage stability and simple regeneration , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

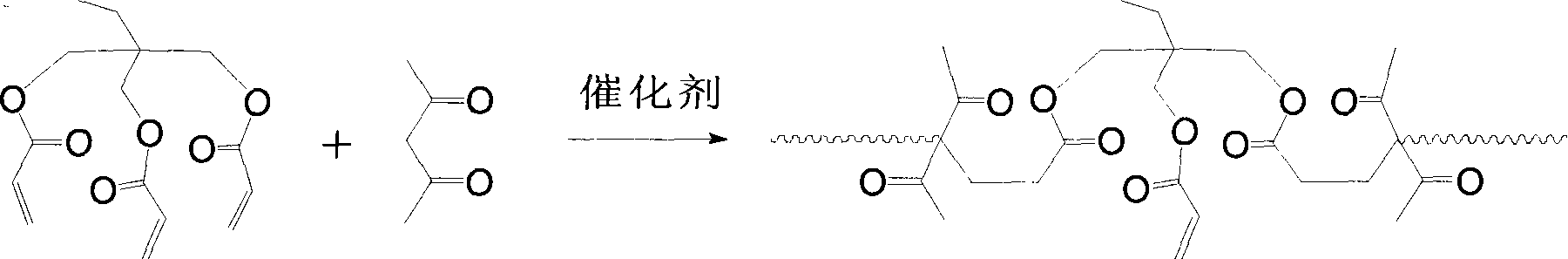

Method used

Image

Examples

Embodiment 1

[0025] 4.0g KF 2H 2Dissolve O in 50ml of water, add 15.0g of 50-120mesh basic alumina, stir at 65-75°C for 1hr, depressurize the water pump, remove water slowly at 70°C, and activate in a muffle furnace at 140°C for 4hrs to obtain fluorine loaded on alumina Potassium chloride solid base catalyst.

[0026] 17.2g of trimethylolpropane triacrylate monomer and 3.6g of ethyl acetoacetate were mixed in a three-neck reaction flask, 0.01g of polymerization inhibitor p-methoxyphenol was added, and 8.0g of the above-mentioned obtained aluminum oxide supported potassium fluoride solid Base catalyst, stir rapidly, heat to 80°C, react for 6 hours, the viscosity of the system increases, stop the reaction, filter while hot, and obtain a light yellow viscous resin with a viscosity of 31000cps / 25°C.

Embodiment 2

[0028] 10.0g D290 type macroporous strongly basic anion-exchange resin (cross-linked polystyrene microspheres support quaternary ammonium salt, and the commercial product uses chloride ion as the exchange ion) is first soaked with deionized water to remove mechanical impurities and pulverized resin, Soak the resin with 100mL of 10% sodium hydroxide aqueous solution for a day and night, filter, rinse with deionized water until the filtrate becomes nearly neutral, rinse with absolute ethanol to remove water, and dry to obtain a strong basic anion exchange resin catalyst.

[0029] 17.2g trimethylolpropane triacrylate monomer and 3.6g ethyl acetoacetate are mixed in three-neck reaction flask, add polymerization inhibitor p-methoxyphenol 0.01g, 8.0g above-mentioned gained strongly basic anion exchange resin as Solid catalyst, stirred rapidly, heated to 80°C, reacted for 6 hours, the viscosity of the system increased, stopped the reaction, filtered while it was hot, and obtained a li...

Embodiment 3

[0031] The aluminum oxide-supported potassium fluoride obtained after filtering in Example 1 was washed with absolute ethanol, dried, and then activated in a muffle furnace at 140°C for 4 hours.

[0032] 17.2g of trimethylolpropane triacrylate monomer and 3.6g of ethyl acetoacetate were mixed in a three-necked reaction flask, and 0.01g of polymerization inhibitor p-methoxyphenol was added, and 8.0g of the above-mentioned activated alumina supported potassium fluoride Solid base catalyst, stirred rapidly, heated to 80°C, reacted for 6 hours, the viscosity of the system increased, stopped the reaction, filtered while it was hot, and obtained a slightly yellow viscous resin with a viscosity of 30600cps / 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com