Tube type continuous flow reaction device and preparation method of isopropyl acetoacetate

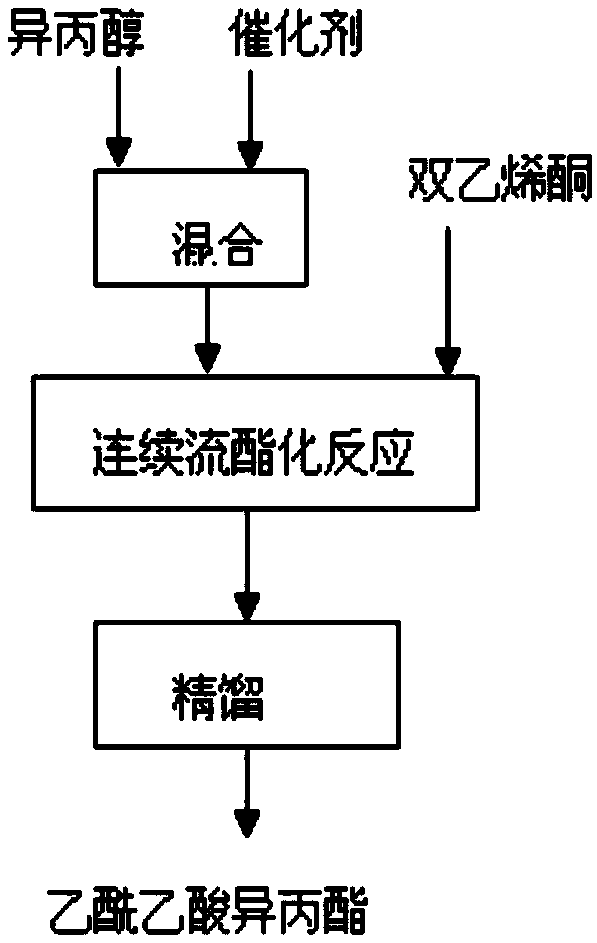

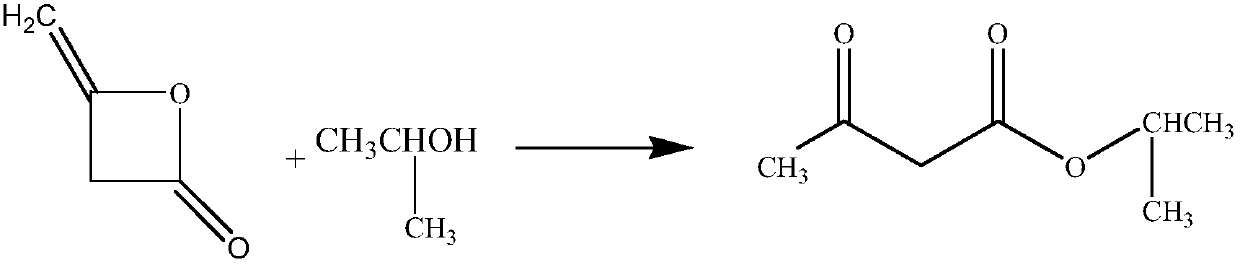

A technology of isopropyl acetoacetate and a reaction device, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of low synthesis yield, high cost, and expensive raw materials, and achieve reduction The effect of generation of side reactions, improvement of yield and content, and simplification of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

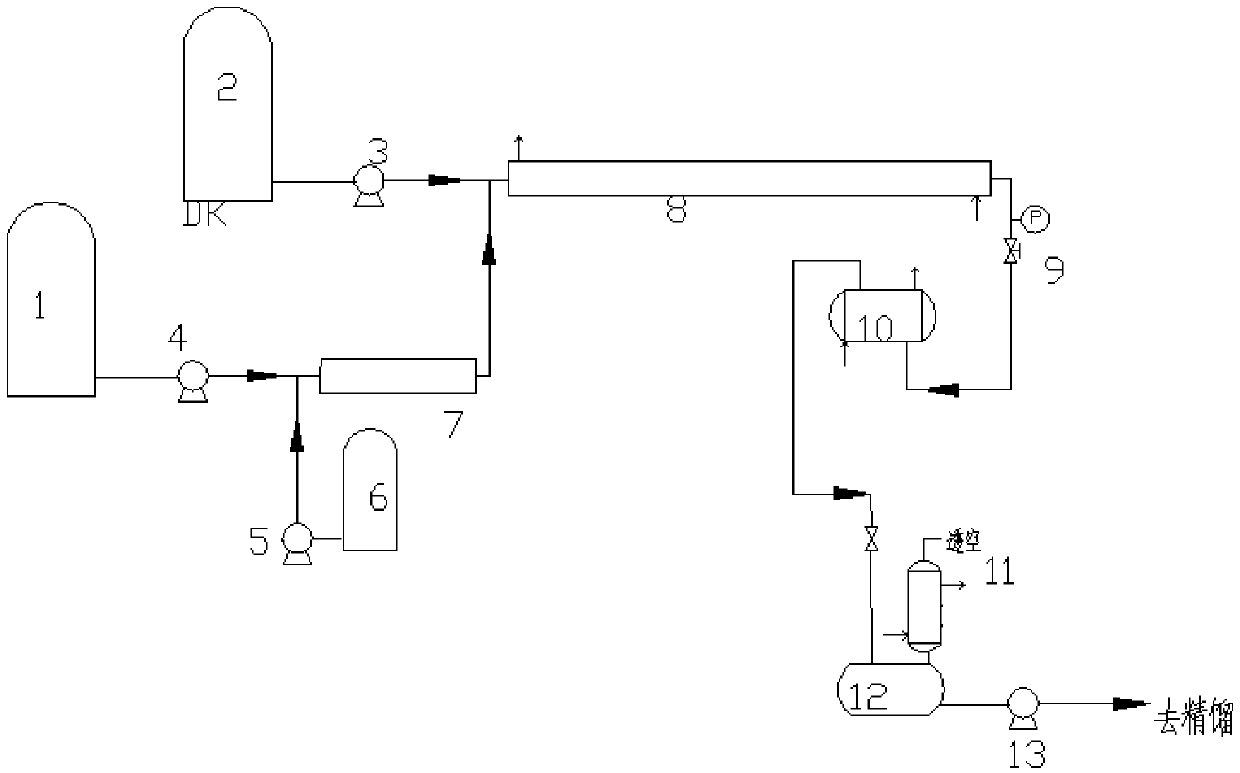

[0046] First, from the isopropanol metering tank 1 and the catalyst metering tank 6, through the metering pumps 4 and 5, the isopropanol and the catalyst are injected into the catalyst mixing section 7 according to a certain flow rate respectively, and after the two are mixed, start the diketene metering pump 3. Then inject the diketene and alcohol solution into the tubular continuous flow reactor 8 at a certain flow rate. The internal mixing unit structure of the tubular reactor is SV type, and the molar ratio of diketene and isopropanol is 1:1.01 , the catalyzer is diethylamine, and the consumption of catalyzer accounts for 0.05% of reactant gross mass, and reaction temperature is 140 ℃, and reaction residence time is 5min, and the reaction pressure is regulated by pressure regulating valve 9, and reaction pressure is 0.6MPa, and crude ester after reaction After being cooled to 35°C by the condenser 10, it flows into the crude ester buffer tank 12, and the low boilers in the ...

Embodiment 2

[0048]First, from the isopropanol metering tank 1 and the catalyst metering tank 6, through the metering pumps 4 and 5, the isopropanol and the catalyst are injected into the catalyst mixing section 7 according to a certain flow rate respectively, and after the two are mixed, start the diketene metering pump 3. Then inject the diketene and alcohol solution into the tubular continuous flow reactor 8 at a certain flow rate. The internal mixing unit structure of the tubular reactor is SX type, and the molar ratio of diketene and isopropanol is 1:1.05 , the catalyzer is triethylamine, and the consumption of catalyzer accounts for 0.13% of reactant gross mass, and reaction temperature is 105 ℃, and reaction residence time is 12min, and the reaction pressure is regulated by pressure regulating valve 9, and reaction pressure is 0.35MPa, and crude ester after reaction After being cooled to 40°C by the condenser 10, it flows into the crude ester buffer tank 12, and the low boilers in th...

Embodiment 3

[0050] First, from the isopropanol metering tank 1 and the catalyst metering tank 6, through the metering pumps 4 and 5, the isopropanol and the catalyst are injected into the catalyst mixing section 7 according to a certain flow rate respectively, and after the two are mixed, start the diketene metering pump 3. Then diketene and alcohol solution are poured into the tubular continuous flow reactor 8 at a certain flow rate. The internal mixing unit structure of the tubular reactor is SH type, and the molar ratio of diketene and isopropanol is 1:1.1 , the catalyst is aniline, the amount of the catalyst accounts for 0.2% of the total mass of the reactants, the reaction temperature is 120°C, the reaction residence time is 21min, the reaction pressure is regulated by the pressure regulating valve 9, the reaction pressure is 0.25MPa, and the crude ester is condensed after the reaction The device 10 is cooled to 45°C, and then flows into the buffer tank 12, the low boilers in the crud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com