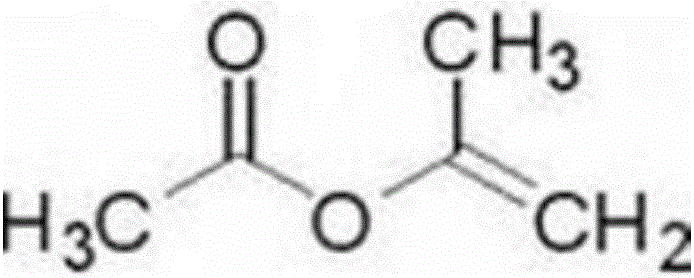

Energy-saving efficient isopropenyl acetate synthesis method

A technology of isopropylene acetate and a synthesis method, which is applied in the preparation of ketene, ketene/polyketene, organic chemistry, etc., can solve the problems of low production efficiency, low reaction efficiency, small contact surface, etc., and achieves improved production efficiency. efficiency, improve reaction efficiency, reduce the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention is a kind of energy-saving and high-efficiency isopropenyl acetate synthetic method, comprises the following steps:

[0026] (1) Put acetic acid into a container, the container is a stainless steel tube, and then heat up the acetic acid to 500-800°C, so that acetic acid is catalytically cracked in the container to generate ketene gas, and the reaction temperature of catalytic cracking is 700-800°C, reaction pressure 200-600mmH, pass the generated ketene gas into the cooler, then add water at 10-35°C to the cooler for preliminary cooling of the ketene gas, ketene and water The molar ratio is: (2.5~3.5):1, and the dripping speed of water is 40ml / min.

[0027] (2) Put the acetone solution into the mixing dish, the mol ratio of the acetone solution and vinyl ketone is: 2:(0.95~1.5), drop the catalyst into the mixing dish simultaneously, the mol ratio of the catalyst and the acetone solution is: (0.8~ 1.5): 1. After mixing and stirring evenly, use a me...

Embodiment 1

[0033] Put the acetic acid into the stainless steel tube, and then heat the acetic acid to 700°C, so that the acetic acid will be catalytically cracked in the stainless steel tube to generate ketene gas, and the generated ketene gas will be passed into the cooler, and then Add water at 15°C to the cooler for preliminary cooling of ketene gas. The molar ratio of ketene to water is 2.7:1, and the dropping rate of water is 40ml / min.

[0034] Put the acetone solution into the mixing dish, the molar ratio of the acetone solution and vinyl ketone is: 2:1, put the catalyst into the mixing dish at the same time, the molar ratio of the catalyst and the acetone solution is: 0.8:1, after mixing and stirring for 30min, use The metering pump pumps the mixed liquid into the cooler, so that the mixed liquid can further cool the ketene gas obtained from the cracking reaction, and the mixed liquid is evaporated into gas at the same time.

[0035] Adjust the temperature of the cooler so that th...

Embodiment 2

[0039] Put the acetic acid into the stainless steel tube, and then heat the acetic acid to 730°C, so that the acetic acid will undergo catalytic cracking in the stainless steel tube to generate ketene gas, pass the generated ketene gas into the cooler, and then Add water at 20°C to the cooler for preliminary cooling of the ketene gas. The molar ratio of ketene to water is 3.1:1, and the dropping rate of water is 40ml / min.

[0040] Put the acetone solution into the mixing dish, the molar ratio of the acetone solution and vinyl ketone is: 2:1.1, put the catalyst into the mixing dish at the same time, the molar ratio of the catalyst and the acetone solution is: 0.95:1, after mixing and stirring for 45min, use The metering pump pumps the mixed liquid into the cooler, so that the mixed liquid can further cool the ketene gas obtained from the cracking reaction, and the mixed liquid is evaporated into gas at the same time.

[0041] Adjust the temperature of the cooler so that the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com