Water-based antirust and antifouling paint used on wall surface and preparation method thereof

A water-based paint and antifouling technology, applied in antifouling/underwater paints, anti-corrosion paints, coatings, etc., can solve the problems of rust spots and reduced decoration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

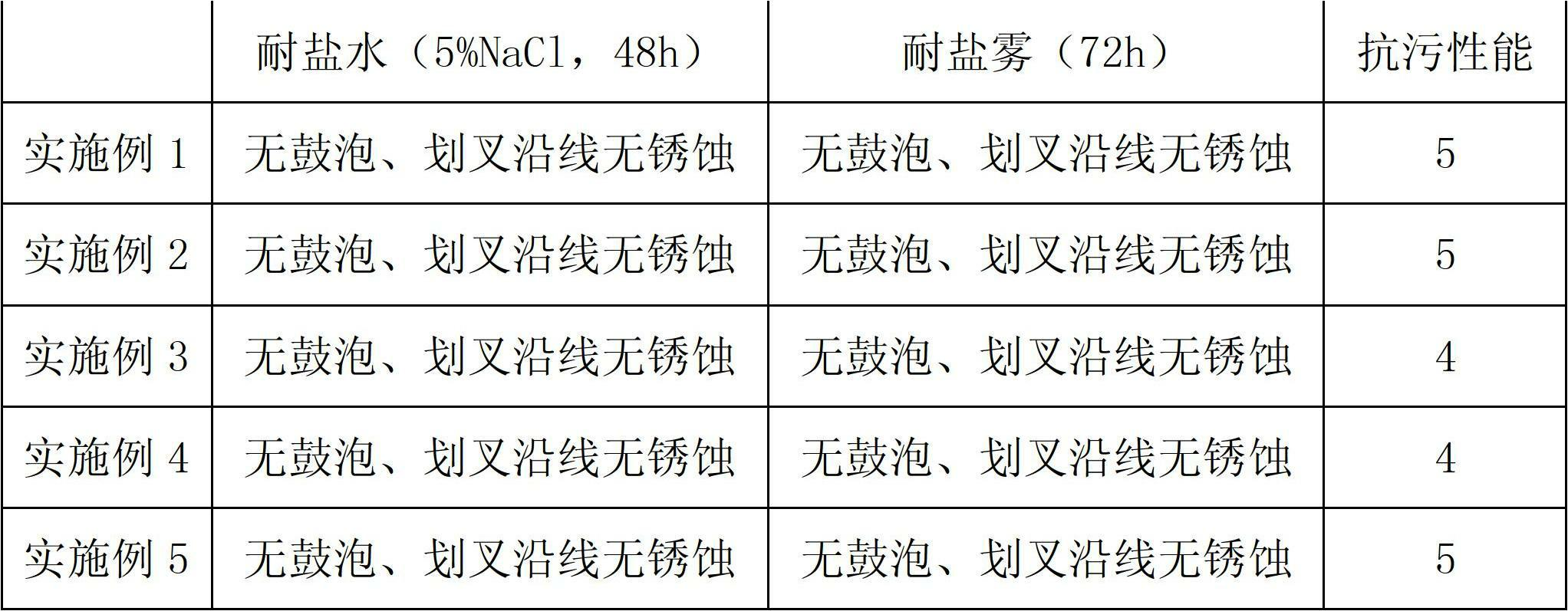

Examples

Embodiment 1

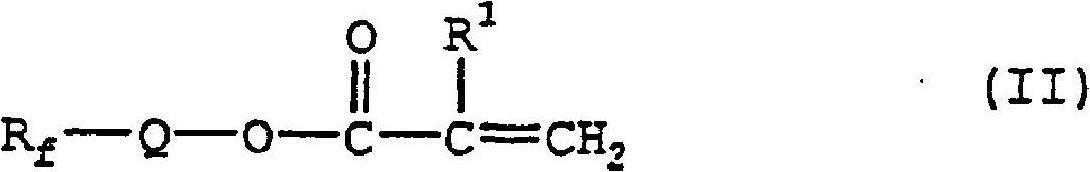

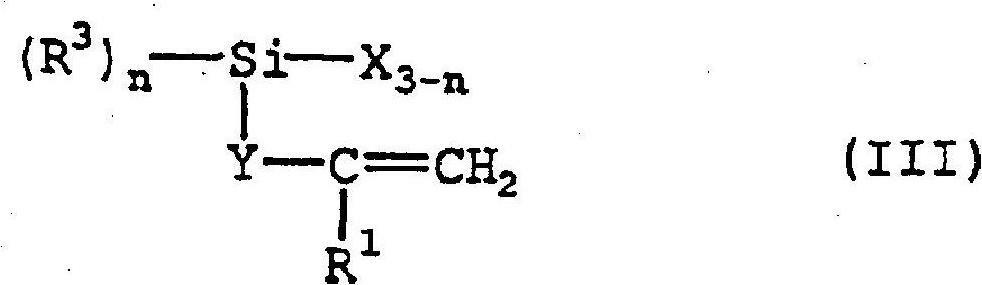

[0091] 20 parts of film-forming substance (styrene-acrylate copolymer emulsion with glass transition temperature of 29°C), 2 parts of film-forming aid, 0.5 part of unsaturated ester monomer containing fluoroaliphatic group and unsaturated The copolymerization product of silane monomer will be (F(CF 2 ) 6 CH 2 OC(=O)C(CH 3 )=CH 2 (Component 1) As an unsaturated ester monomer containing a fluoroaliphatic group, (C 2 h 5 O) 3 SiCH=CH 2As an unsaturated silane monomer, prepared according to the preparation process provided by the present invention), 1 part of cosolvent (1,2-propylene glycol), 1 part of pH regulator (2-amino-2methyl-1-propanol), 0.1 part of corrosion inhibitor (amino carboxylate) and appropriate amount of water.

[0092] Utilize the preparation method provided by the invention to prepare paint, and adjust the viscosity of paint to 89KU.

Embodiment 2

[0094] 40 parts of film-forming substance (styrene-acrylate copolymer emulsion with glass transition temperature of 14°C), 5 parts of film-forming aid, 2 parts of unsaturated ester monomer containing fluoroaliphatic group and unsaturated Copolymerization products of silane monomers (C 7 f 15 SO 2 N(C 2 h 5 )C 2 h 4 OC(=O)C(CH 3 )=CH 2 As a fluorinated aliphatic group unsaturated ester monomer, (C 2 h 5 O) 3 SiCH=CH 2 As an unsaturated silane monomer, prepared according to the preparation process provided by the present invention), 5 parts of cosolvent (1,2-propylene glycol), 0.1 part of pH regulator (2-amino-2methyl-1-propanol), 1 part of corrosion inhibitor (nitrocarboxylate) and appropriate amount of water, 0.5 part of dispersant (polycarboxylate sodium salt type dispersant).

[0095] Utilize the preparation method provided by the invention to prepare paint, and adjust the viscosity of paint to 85KU.

Embodiment 3

[0097] 60 parts of film-forming substance (styrene-acrylate copolymer emulsion with glass transition temperature of 20°C), 10 parts of film-forming aid, 1 part of unsaturated ester monomer containing fluoroaliphatic group and unsaturated The copolymerization product of silane monomer (will c-C 6 f 11 CH 2 OC(=O)C(CH 3 )=CH 2 As an unsaturated ester monomer containing a fluorinated aliphatic group, (C 2 h 5 O) 3 SiCH=CH 2 As an unsaturated silane monomer, prepared according to the preparation process provided by the present invention), 2 parts of cosolvent (1,2-propylene glycol), 0.5 parts of pH regulator (2-amino-2methyl-1-propanol), 0.5 part of corrosion inhibitor (nitrocarboxylate) and appropriate amount of water, 0.1 part of dispersant (polycarboxylate sodium salt type dispersant), 1 part of defoamer (mixture of hydrophobic silica and mineral oil).

[0098] Utilize the preparation method provided by the present invention to prepare coating, and the viscosity of coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com