Patents

Literature

47results about How to "Labor-saving construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

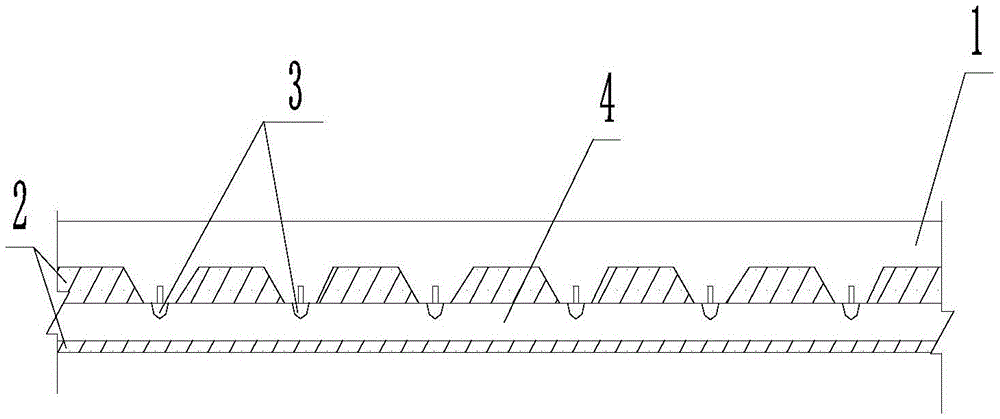

Method for planting vegetation on the karst area slope

InactiveCN101543168AImprove adhesionAvoid churnCultivating equipmentsSoilless cultivationGrowth plantSurface layer

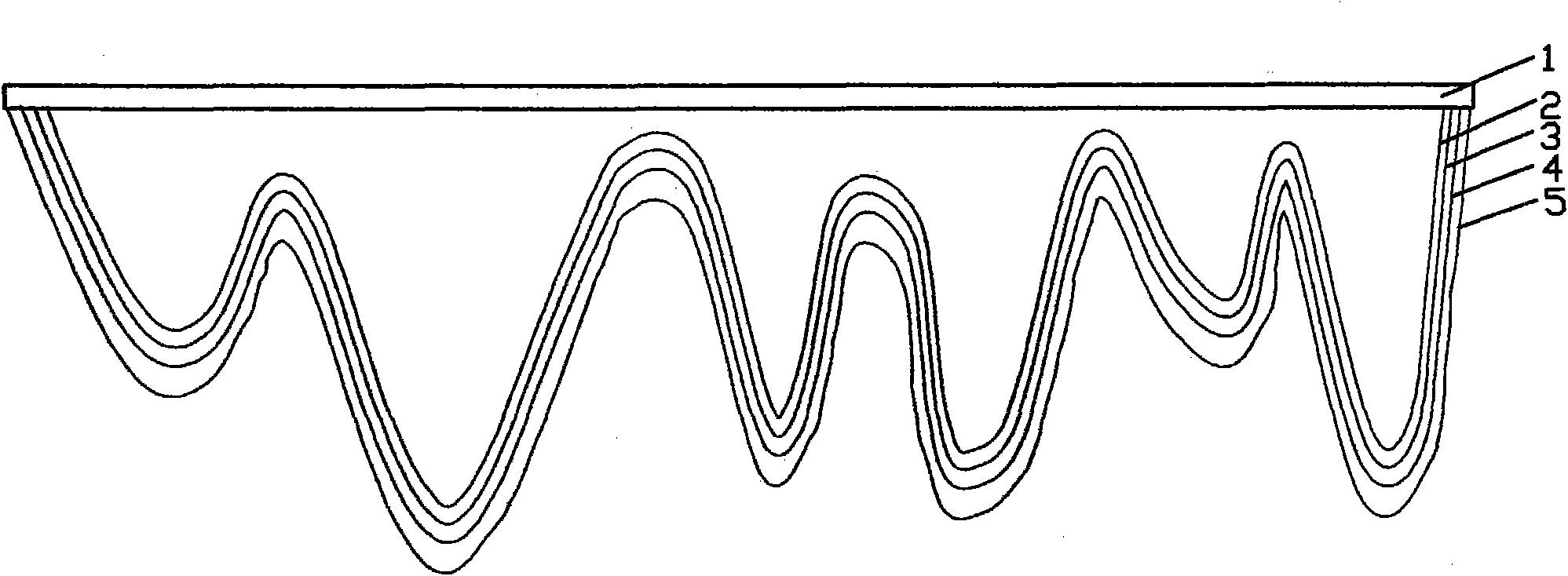

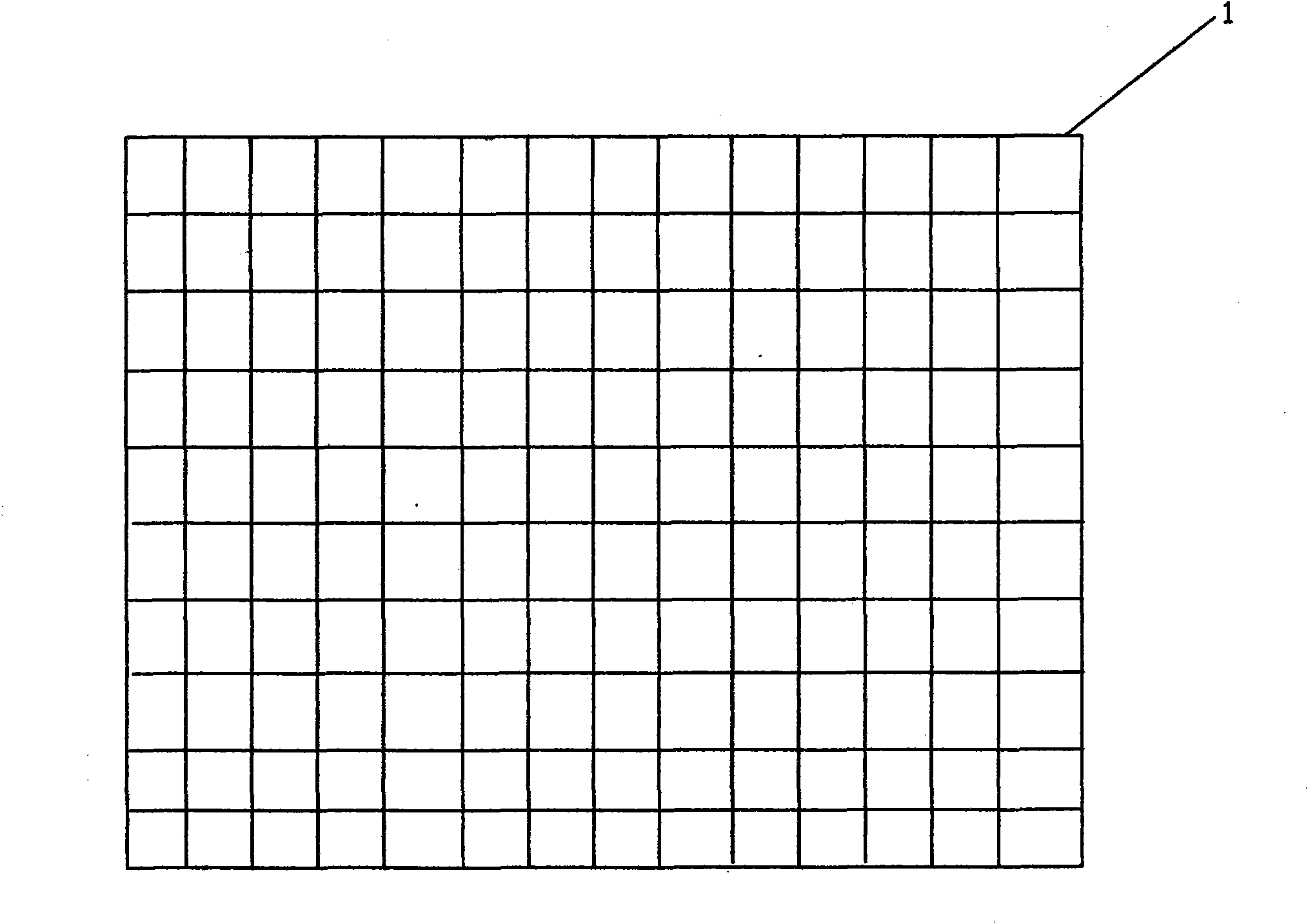

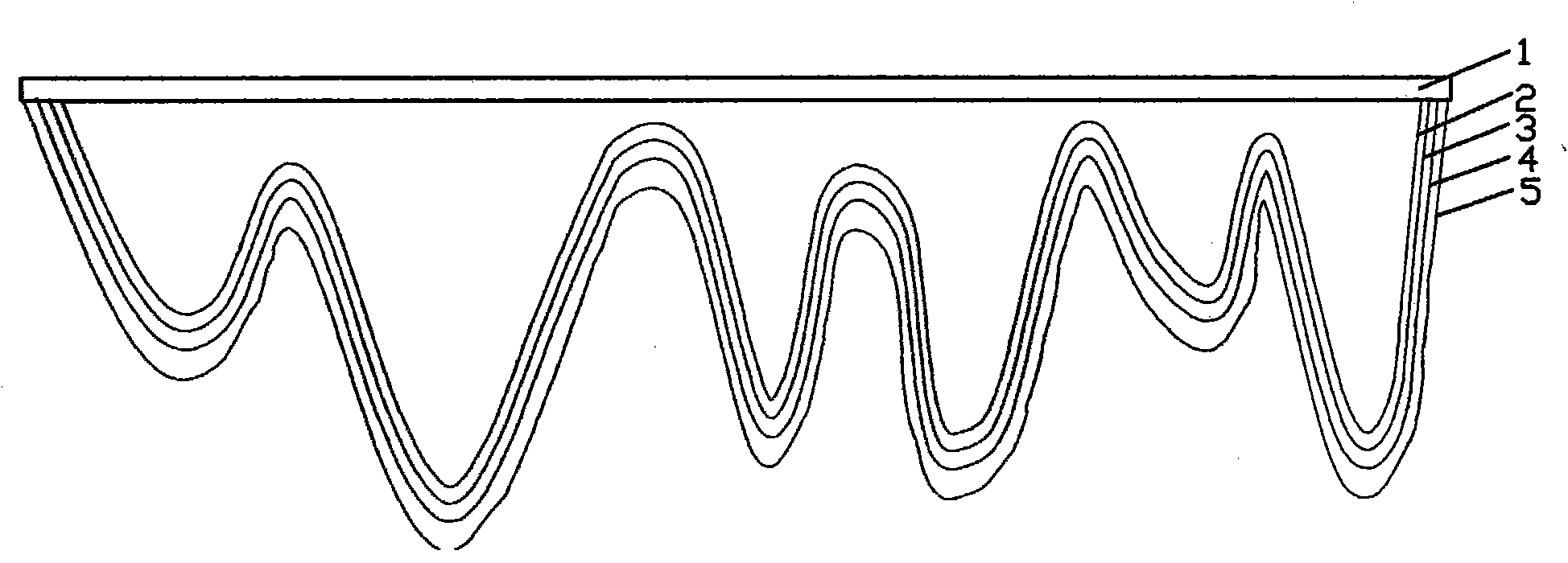

The invention discloses a method for planting vegetation on the karst area slope, comprising: laying and fixing a wave shape plant-growing net with meshes on the slope surface, wherein the wave shape plant-growing net can be formed by connecting a surface layer net and a wave shape net and also can be formed by connecting the surface layer net, the wave shape net and the bottom layer net; spraying the artificial soil for the shrub slope protection in the karst area on the wave shape plant-growing net by a mechanical or an artificial operation method, and spraying the plant growth substrate mixed with the plant seeds on the top of the artificial soil by a sprayer. The invention lays the wave shape plant-growing net with the meshes on the shrub slope protection in the karst area, therefore, the sprayed artificial soil and seeds during laying the planting substrate can absorb in the wave shape plant-growing net with the meshes. The invention provides an adhesion platform for the artificial soil and seeds to ensure the root system expansion during plant growth, promotes the construction speed and saves the construction cost.

Owner:贵州边坡生态防护研究所有限责任公司

Mortar additive and production process thereof

The invention belongs to the technical field of construction material, and particularly relates to a mortar additive, wherein the mortar additive comprises the following components in parts by weight: 1-12 parts of cellulose ether, 20-80 parts of polymer latex powder, 20-70 parts of thixotropic agent and 0.1-0.7 part of air entraining agent. The production process of the mortar additive solves the problems that the mixed mortar has low quality; the mixed mortar has poor workability, is dry and difficult to scrape; the bonding strength is low, the phenomena of hollowing and dropping are easy to appear; the shrinkage is big, the surface is easy to crack and the like. The mortar mixed with the mortar additive provided by the invention has the advantage of high combination property, such as construction property, water retention, compressive strength, bonding strength, cracking resistance and the like.

Owner:黄明杰

Water-based heavy-duty single-component on-rust primer, and preparation method and application thereof

The invention discloses a water-based heavy-duty single-component on-rust primer, and a preparation method and application thereof. The water-based heavy-duty single-component on-rust primer is composed of deionized water, a main conversion agent, an auxiliary conversion agent, a penetrant, a film forming assistant, an antifreezing agent, a preservative, a thickener, a filler, a defoaming agent, a dispersing agent, a pH regulator, a film forming material and a substrate wetting agent. The temperature of the used substrate can not be too high, the humidity can not be greater than 85%, the one-time spray coating can not be too thick, and the position for electric welding is reserved. The product is stored at 5-40 DEG C in a ventilating cool dry place, and the construction temperature is preferably 10-40 DEG C. The primer can be applied by brush coating, roller coating, air spraying or airless spraying, the particular mode can be selected according to the on-site construction environment and climate conditions, and brush coating and airless spraying are suggested if conditions permit.

Owner:山东兴鲁化工股份有限公司

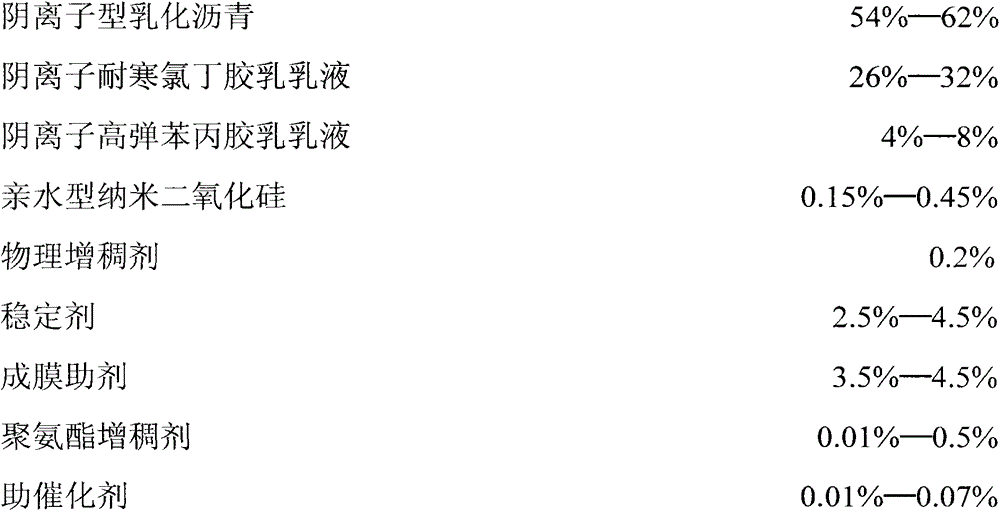

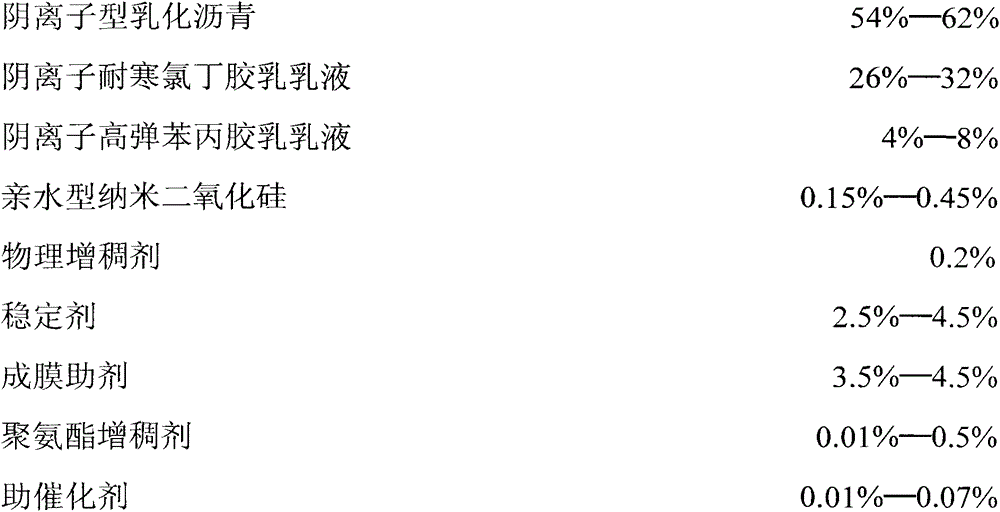

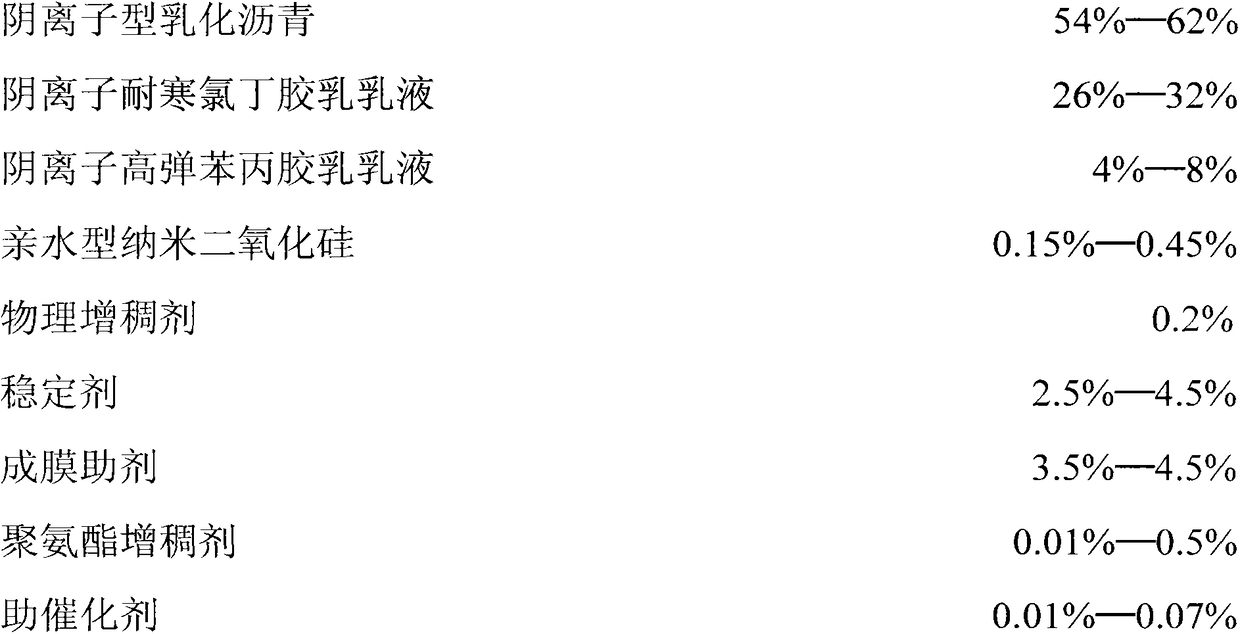

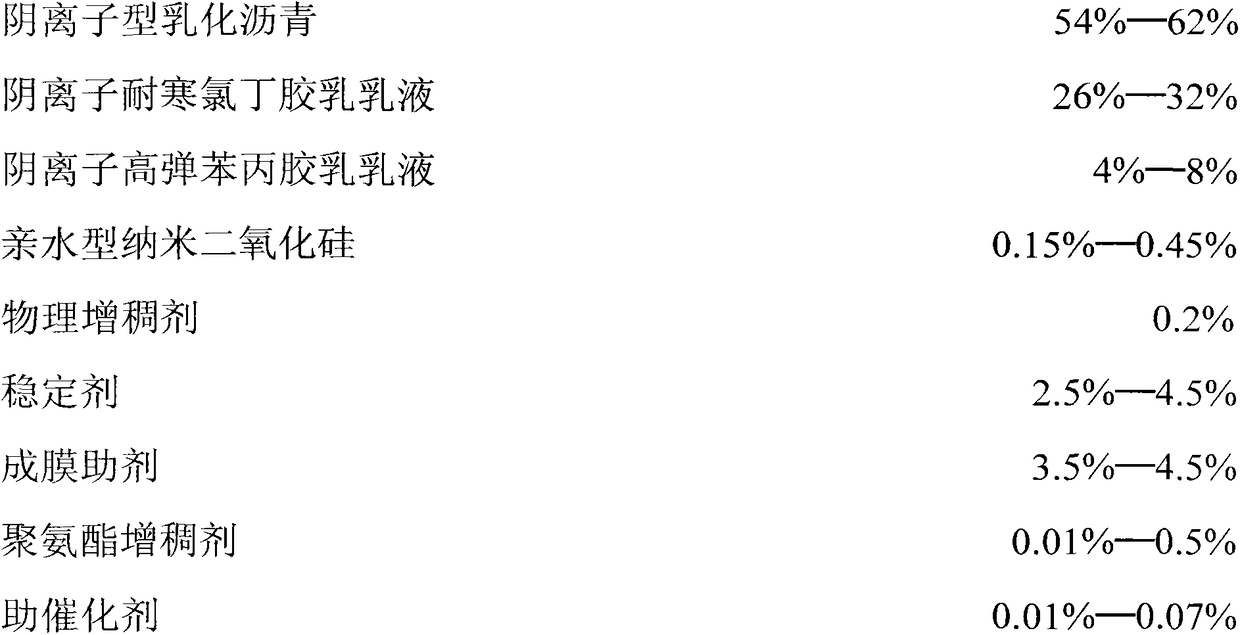

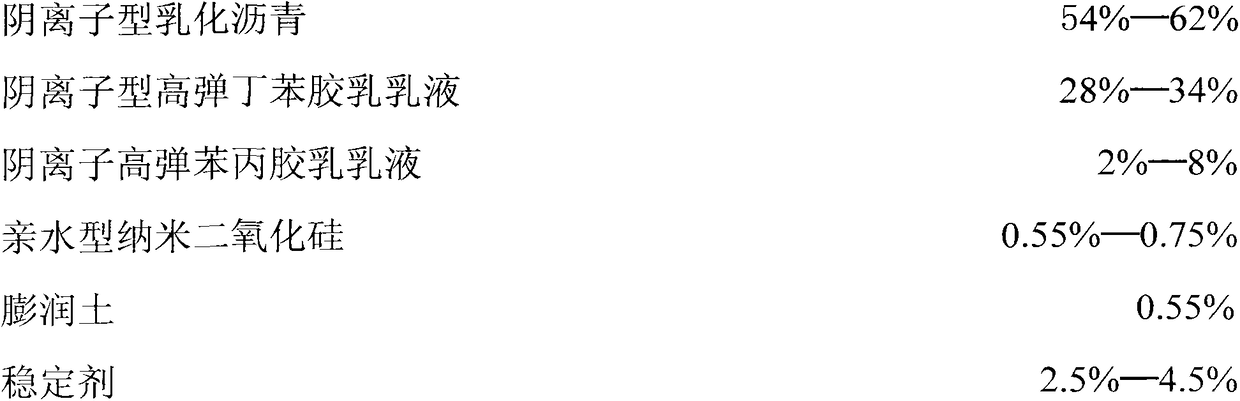

Sprayed quick-setting liquid rubber waterproof coating and preparation method thereof

ActiveCN104099022ALower requirementConstruction labor savingConjugated diene hydrocarbon coatingsChloropene polymer coatingsSelf-healingCorrosion

The invention discloses a sprayed quick-setting liquid rubber waterproof coating. The coating comprises a component A, a component B and a component C, the component A is a waterproof material host solution, the component B is a catalyst and de-emulsifier solution, and the component C is a reinforcing fiber solution. A preparation method of the waterproof coating comprises the following steps: respectively preparing the component A, the component B and the component C, jetting the above three components through independent feeding and discharging systems to realize contact, mixing and reaction of the atomized component A, component B and component C, quickly molding after falling to the ground, precipitating to obtain reaction water, and bonding the above obtained A and B mixture to the component C reinforcing fiber through a special roll in order to form an overall seamless fiber reinforced membrane. The coating has the advantages of quick film forming 4s after spraying, excellent adhesiveness, high elastic self-healing, high elongation of above 600%, strong abnormal adhesion, strength reaching above 0.7MPa, strong corrosion resistance and high and low temperature resistance.

Owner:世纪洪雨(德州)科技有限公司

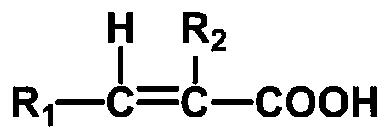

Preparation method and application of viscosity-reducing polycarboxylate water reducer

The invention provides a preparation method of a viscosity-reducing polycarboxylate superplasticizer and an application thereof. The viscosity-reducing polycarboxylate superplasticizer can remarkably reduce the viscosity of concrete on the premise of guaranteeing high water reduction and high slump loss resistance; and the preparation method has the advantages of simple technology, low cost, little pollution and the like. In the preparation method, a specific unsaturated acid monomer, a specific unsaturated polyether macromonomer and N-(4-vinyl benzyl)-N, N-dialkylamine in a molar ratio of (2.5-6.5):1:(0.05-0.2) are subjected to free radical copolymerization reaction to obtain the viscosity-reducing polycarboxylate superplasticizer.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

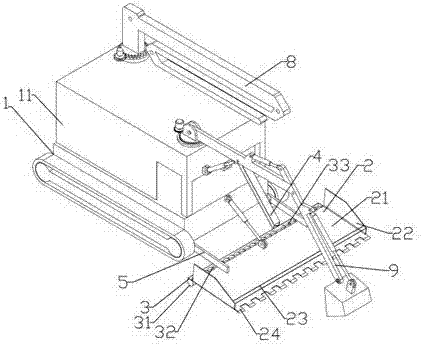

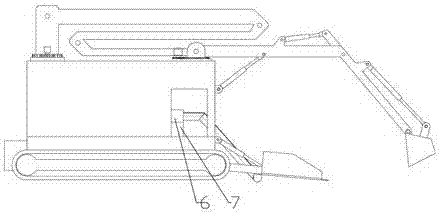

Environmentally friendly efficient silt remover and construction method thereof

ActiveCN107299654AEasy to operateEasy to cleanSoil-shifting machines/dredgersScrew conveyorEnvironmentally friendly

The invention discloses an environmentally friendly efficient silt remover and a construction method thereof. The environmentally friendly efficient silt remover comprises a silt transportation device, wherein the silt transportation device comprises a traveling trolley body; the traveling trolley body is provided with a box; a silt shoveling mechanism is arranged at the front end of the box; two spiral conveyors are arranged between the silt shoveling mechanism and the traveling trolley body; silt is fed into a sorting mechanism in the box so as to sort the silt and sundries, qualified silt which is sorted by the sorting mechanism is discharged via a collecting tube and a discharging tube, and the large sundries are discharged by an outlet of a sorting barrel. In a silt removing process, the environmentally friendly efficient silt remover has the characteristics of convenience in operation, convenient in cleaning, efficient construction and labor saving. Meanwhile, silt is sorted directly by the sorting mechanism, secondary environment pollution is avoided, and the environmentally friendly efficient silt remover is environmentally friendly.

Owner:范广书

Wall-like brick high-molecular hard wall decorative material and preparation method thereof

InactiveCN105778341ALow costNot brokenFireproof paintsAntifouling/underwater paintsPolyesterAssembly line

The invention relates to a wall-like brick high-molecular hard wall decorative material, comprising a base material, a printing mask and a polyester coating layer, wherein the base material and the printing mask are laminated together by hot pressing, and the polyester coating layer is coated as a net on the surface of the printing mask. A preparation method of the wall-like brick high-molecular hard wall decorative material comprises the following steps: 1, preparing the base material; 2, preparing the printing mask; 3, printing a mask; 4, performing hot-pressing lamination; 5, performing net coating of polyester; 6, curing; and 7, performing mould pressing cutting. The wall-like brick high-molecular hard wall decorative material provided by the invention has the advantages of avoiding mildew, having fire resistance, and being high in strength, hardness, degree of finish, brightness, and simulation view; and the preparation method has the advantages of being low in production cost, high in quality of products, and high in assembly line output.

Owner:JIANGYIN HUADONG DECORATIVE MATERIAL

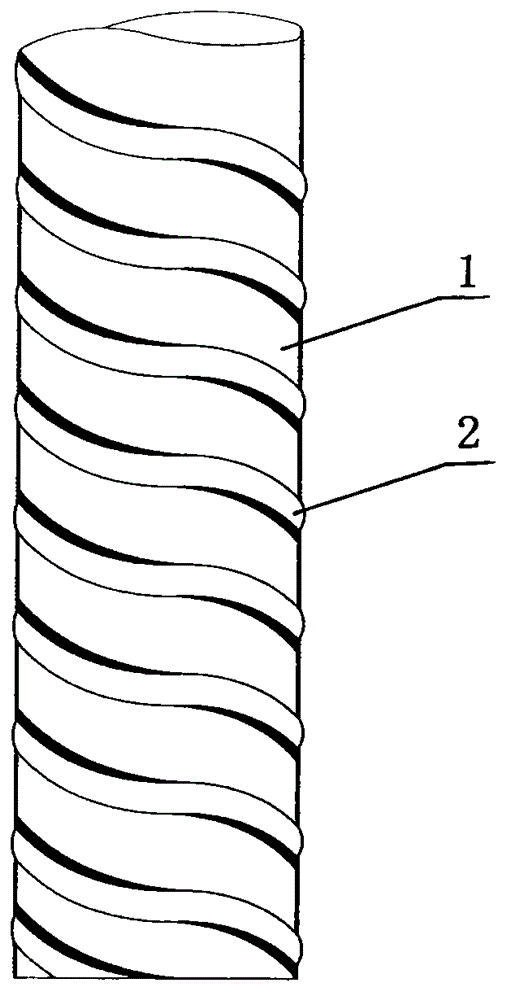

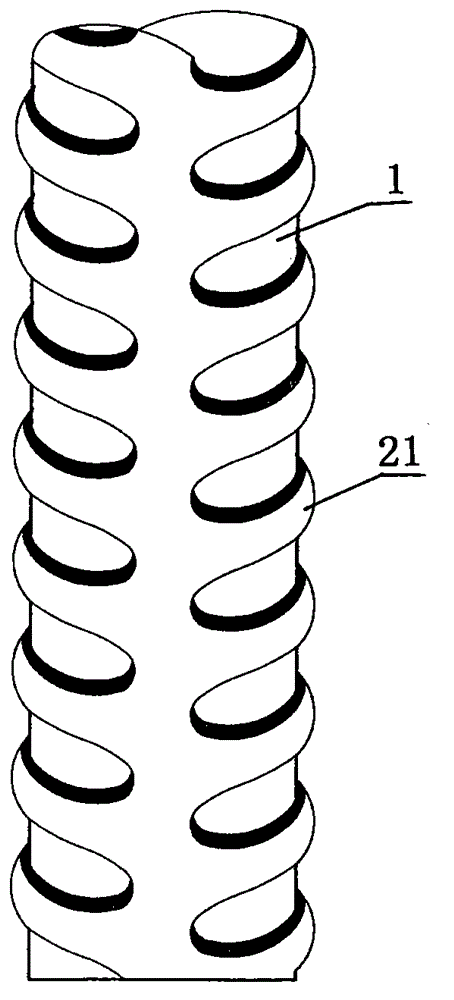

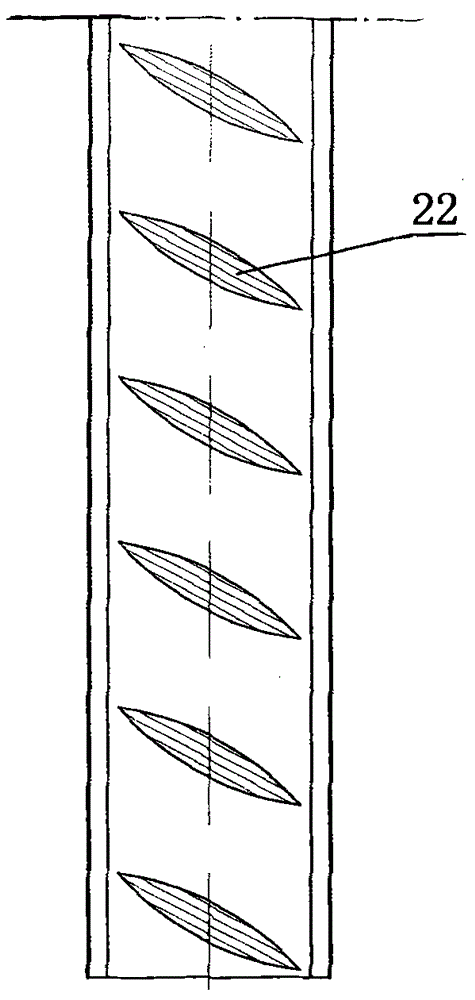

Rib-line-shaped prestressed concrete pipe pile

InactiveCN104963337AIncrease coefficient of frictionImprove bearing capacityBulkheads/pilesPre stressEngineering

The invention belongs to a rib-line-shaped prestressed concrete pipe pile. The rib-line-shaped prestressed concrete pipe pile is composed of a pile body, wherein protruding rib lines or protruding movable outer expanding wings are arranged on the peripheral wall of the pile body. The rib lines are rectangular strip-shaped bodies which are spirally distributed at intervals. The rib lines are equal-height rib bodies which are arranged at intervals. The rib lines are crescent rib bodies which are arranged at intervals, and the crescent rib bodies are obliquely arranged and are arranged independent of one another. Prestressed reinforcement formworks are arranged in the pile body at intervals, and the pile body is round or square. The friction coefficient of the concrete pipe pile and a foundation soil layer can be substantially increased, and the pipe pile has the advantages that the pipe pile is high in bearing and supporting force and free of sedimentation, labor and effort are saved in the construction process, and the service life of a building is long.

Owner:徐俊

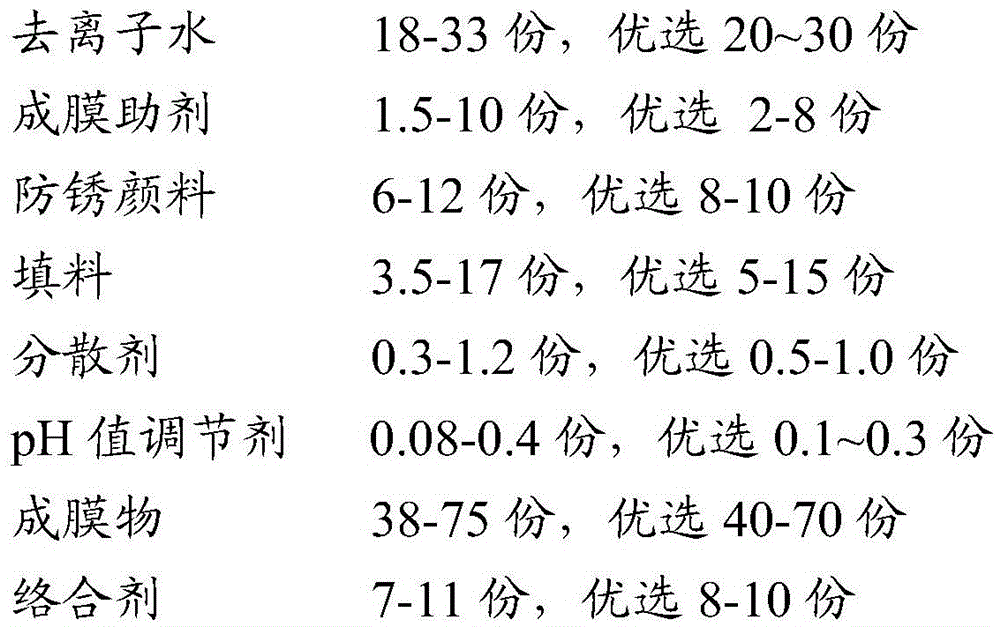

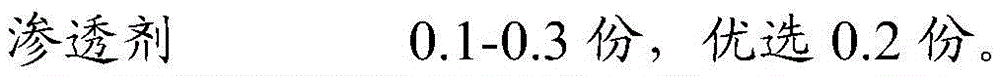

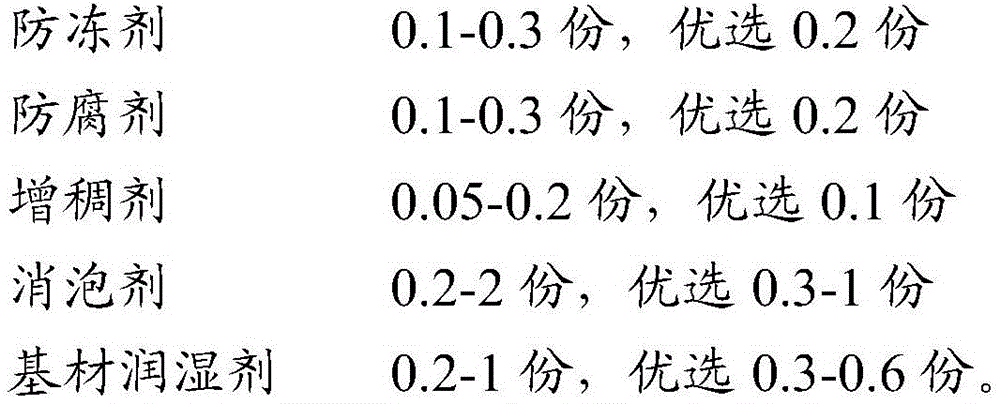

Water-based heavy-duty single-component primer, as well as preparation method and application thereof

InactiveCN106811040AIncreased sealing performanceAnti-rust for a long timeAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryHeavy duty

The invention relates to a water-based heavy-duty single-component primer, which is prepared from the following components in parts by mass: 18 to 33, preferably 20 to 30, parts of de-ionized water, 1.5 to 10, preferably 2 to 8, parts of a coalescing agent, 6 to 12, preferably 8 to 10, parts of an anti-rust pigment, 3.5 to 17, preferably 5 to 15, parts of filler, 0.3 to 1.2, preferably 0.5 to 1.0, part of a dispersant, 0.08 to 0.4, preferably 0.1 to 0.3, part of a pH regulator, 38 to 75, preferably 40 to 70, parts of a film former, 7 to 11, preferably 8 to 10, parts of a complexing agent and 0.1 to 0.3, preferably 0.2, part of a penetrant. The invention also provides a preparation method and application of the water-based heavy-duty single-component primer.

Owner:杨卫兵

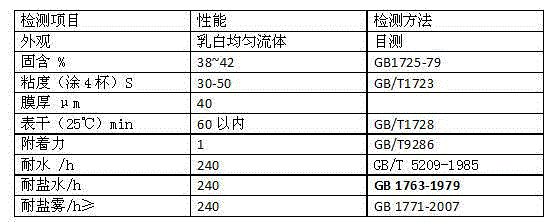

Derusting antirust colored heavy-duty single-component primer and production technique thereof

InactiveCN105038423AStrong adhesionImproves strength and hardnessAnti-corrosive paintsWater basedEmulsion

The invention discloses a derusting antirust colored heavy-duty single-component primer and a production technique thereof. The primer comprises the following components in parts by weight: 5-20 parts of deionized water, 20-25 parts of derusting rust inhibitor, 2-8 parts of film formation assistant, 2-4 parts of antifreezing agent, 0.1-0.2 part of thickener, 3-10 parts of color paste, 0.3-1 part of defoaming agent, 40-70 parts of film forming matter, 3-5 parts of adhesion modifier and 0.3-0.6 part of substrate wetting agent. The production technique comprises the following steps: mixing the components, and stirring and dispersing in a stainless steel reaction kettle; and after all the indexes are qualified through detection and the stirring is finished, filtering through a 100-mesh filter screen, and packaging. The 1318 or KX-123 product is used as the derusting rust inhibitor, the H602 emulsion is used as the film former, and the film formation assistant, substrate wetting agent, imported color paste and other pollution-free assistants are added to prepare the water-based environment-friendly derusting antirust colored single-component primer. The primer has the advantages of accessible raw materials, derusting labor saving, high antirust property, high safety, environment friendliness and high corrosion resistance.

Owner:NANTONG REPAIR AIR CHEM BIOENG

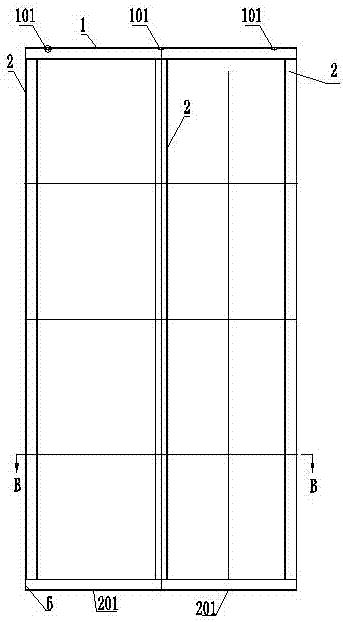

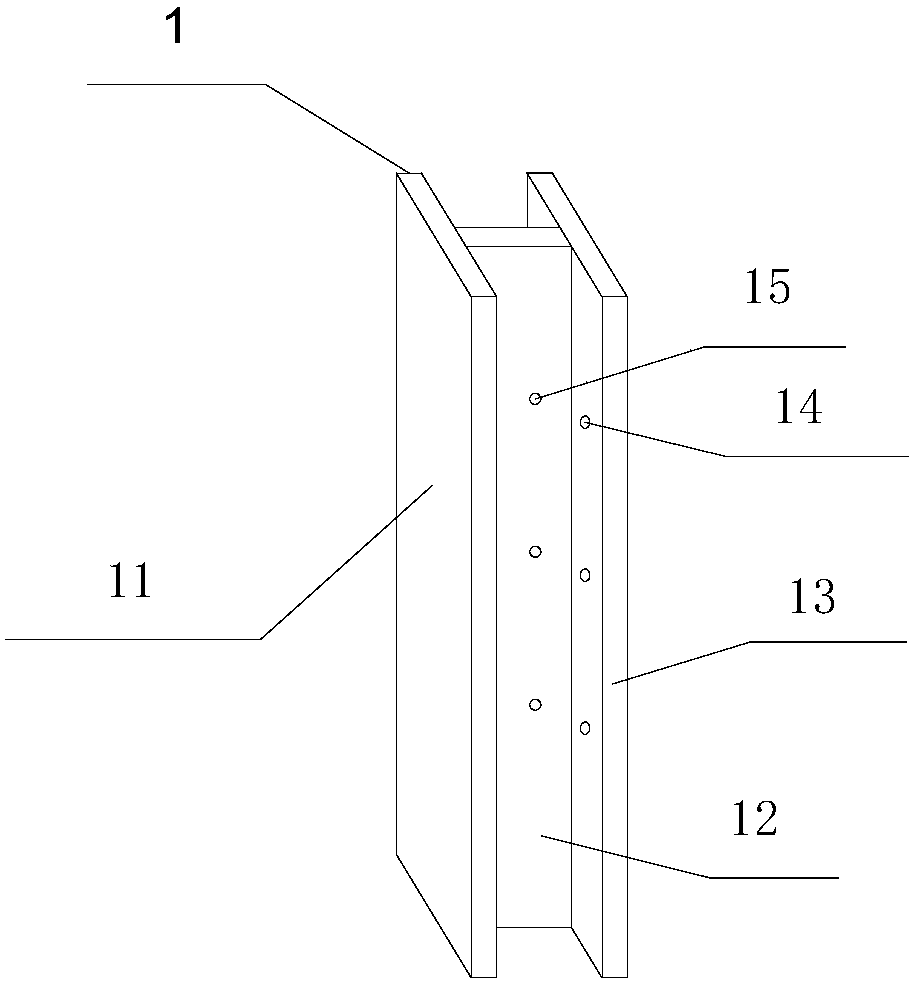

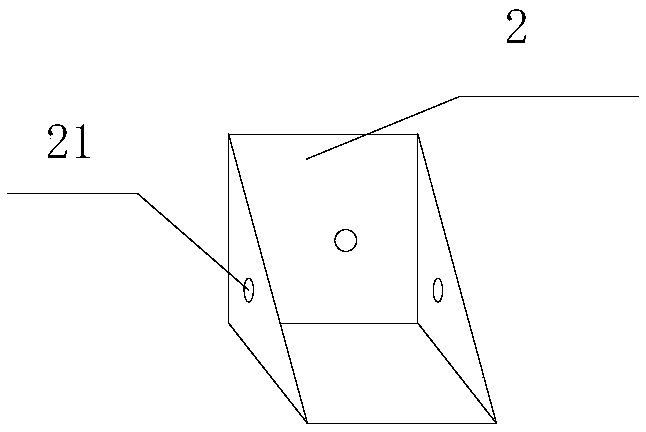

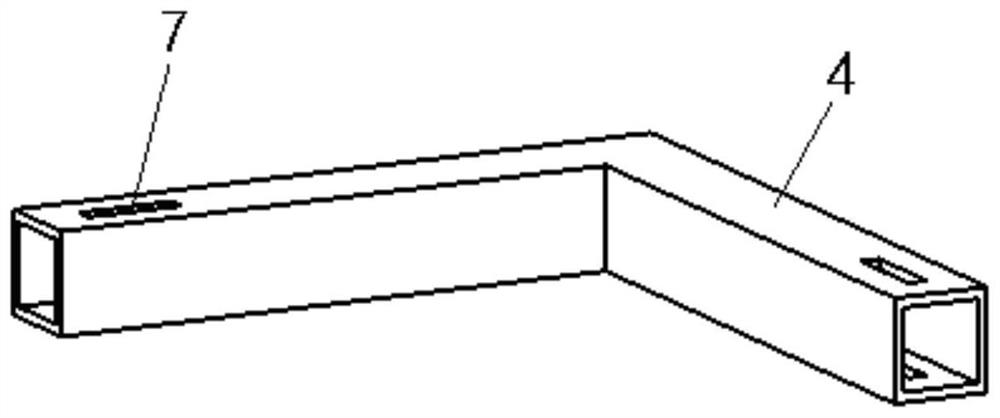

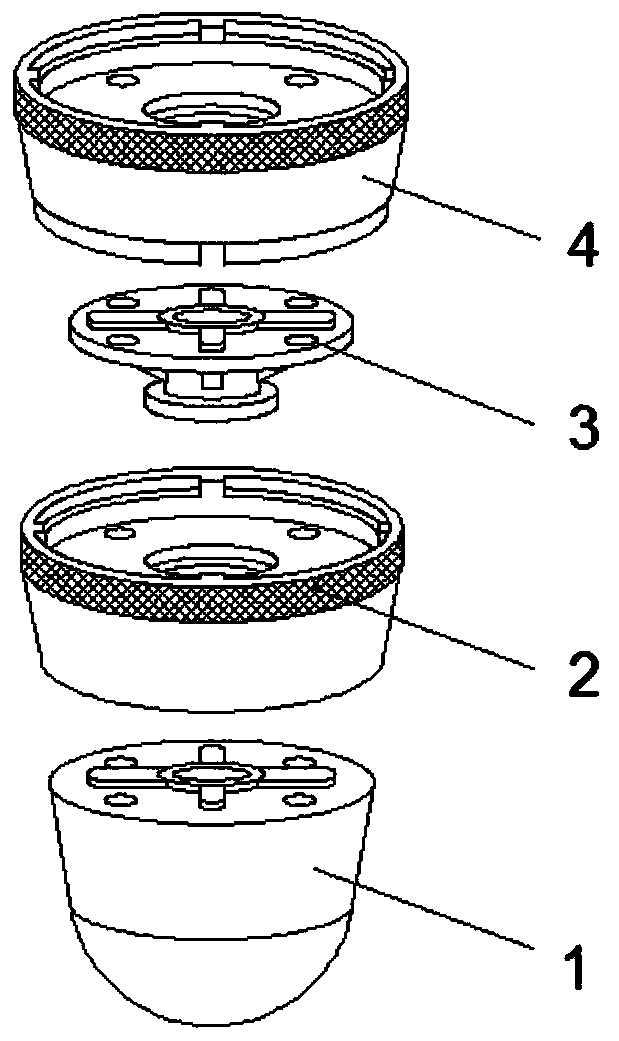

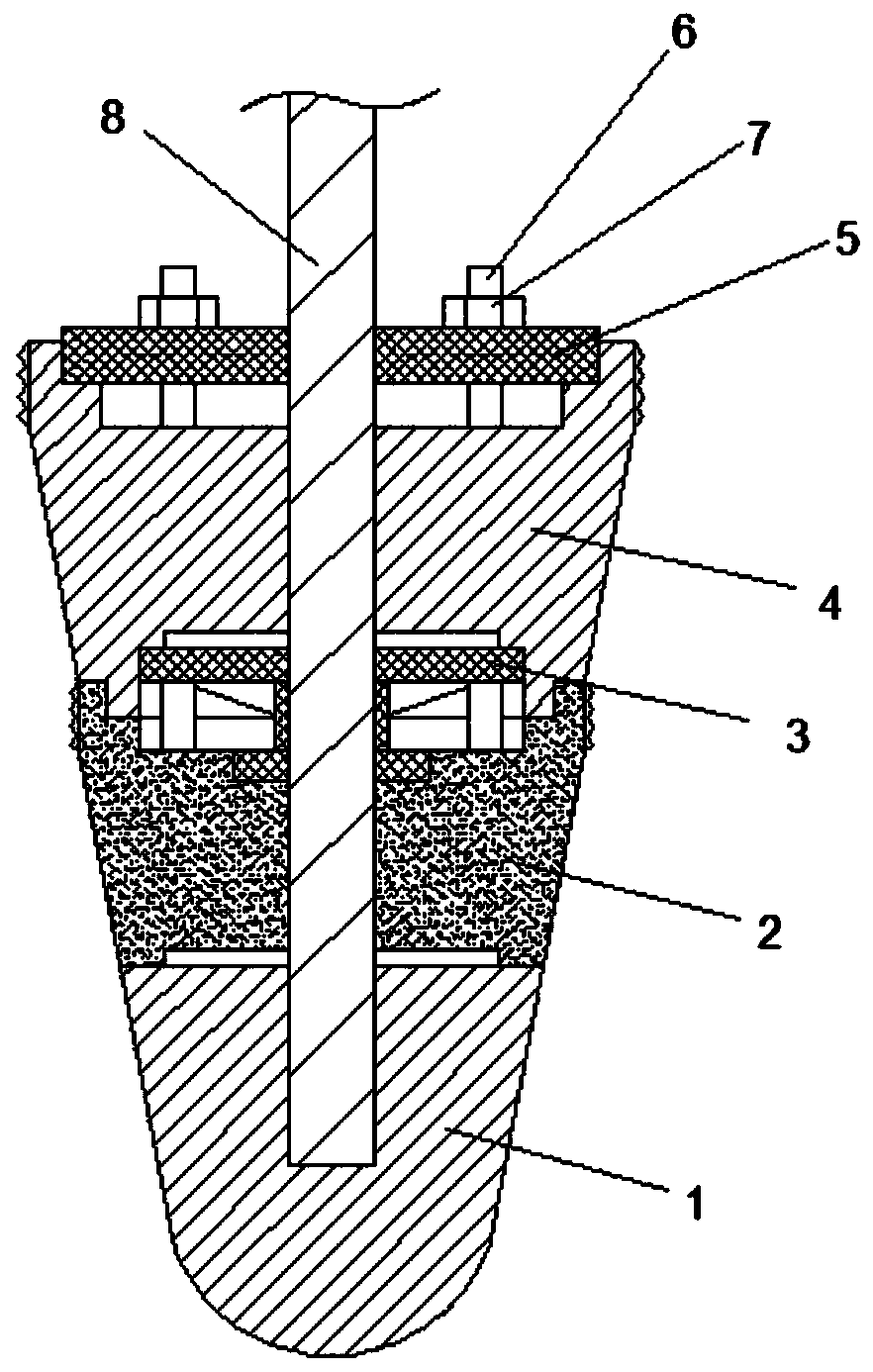

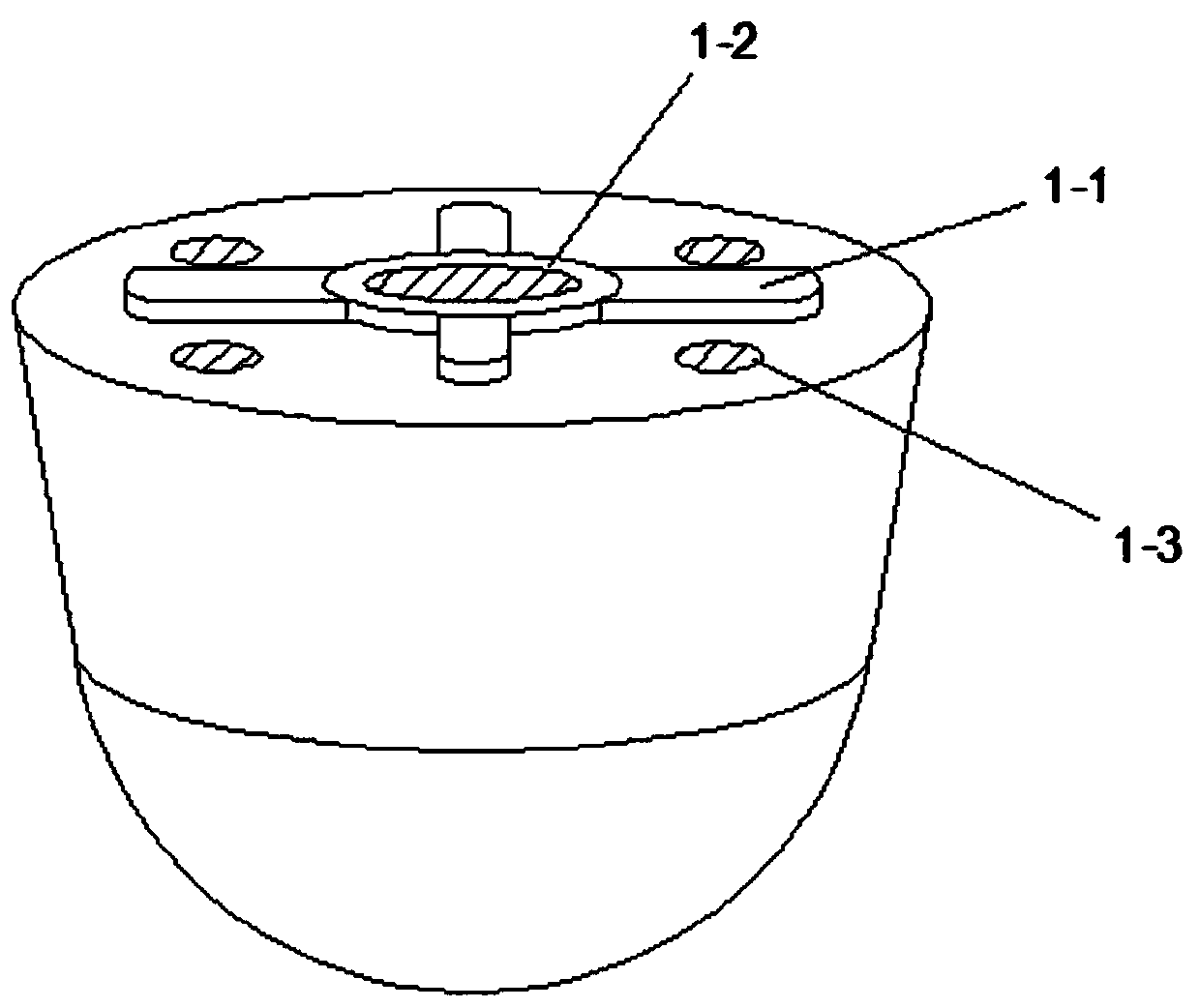

Frame spinning plug-in type integrated inner partition wall plate and installation method thereof

The invention discloses a frame spinning plug-in type integrated inner partition wall plate. The plate is composed of a steel frame, an inner insulation layer, a base layer plate, a surface layer plate, a decorative plate and a frame decoration strip. The steel frame comprises an upper crosspiece, a lower crosspiece, a vertical brace, a horizontal brace tube, a spinning screw pin, a fixing pin, a guide sleeve and a movable pin. The upper crosspiece and the lower crosspiece are vertically connected with the vertical brace. The upper crosspiece is provided with a flanged hole. The vertical brace is provided with a through hole. The horizontal brace tube is fixedly connected with the vertical brace after penetrating through the through hole of the vertical brace. The guide sleeve is vertically connected with the lower crosspiece after penetrating through a through hole of the lower crosspiece. The fixing pin and the through hole of the vertical brace are fixed vertically. The spinning screw pin comprises a screw rod. The screw rod is sleeved with a fixed nut and a movable nut. The fixed nut and the middle of the screw rod are fixedly connected. The frame spinning plug-in type integrated inner partition wall plate has the advantages of being light, thin, high in expressive force, stain-resistant and self-cleaning, A-level fireproofing, anti-knock and anti-cracking, anti-freeze-thaw, acid and alkali resistant, recyclable in using, and low in construction cost.

Owner:NANTONG CHENGYUE DECORATION GRP

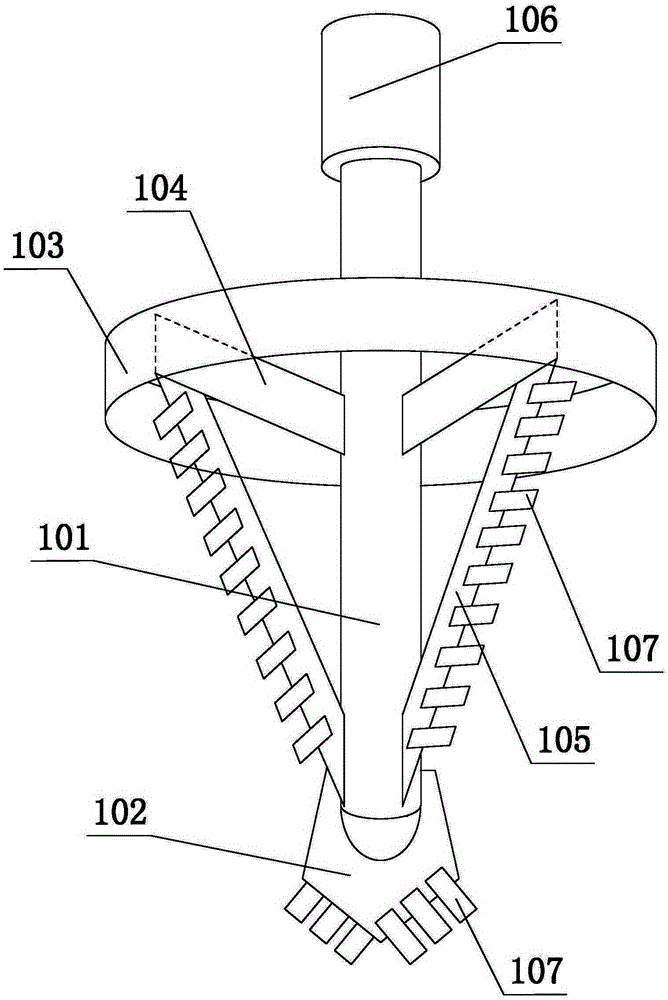

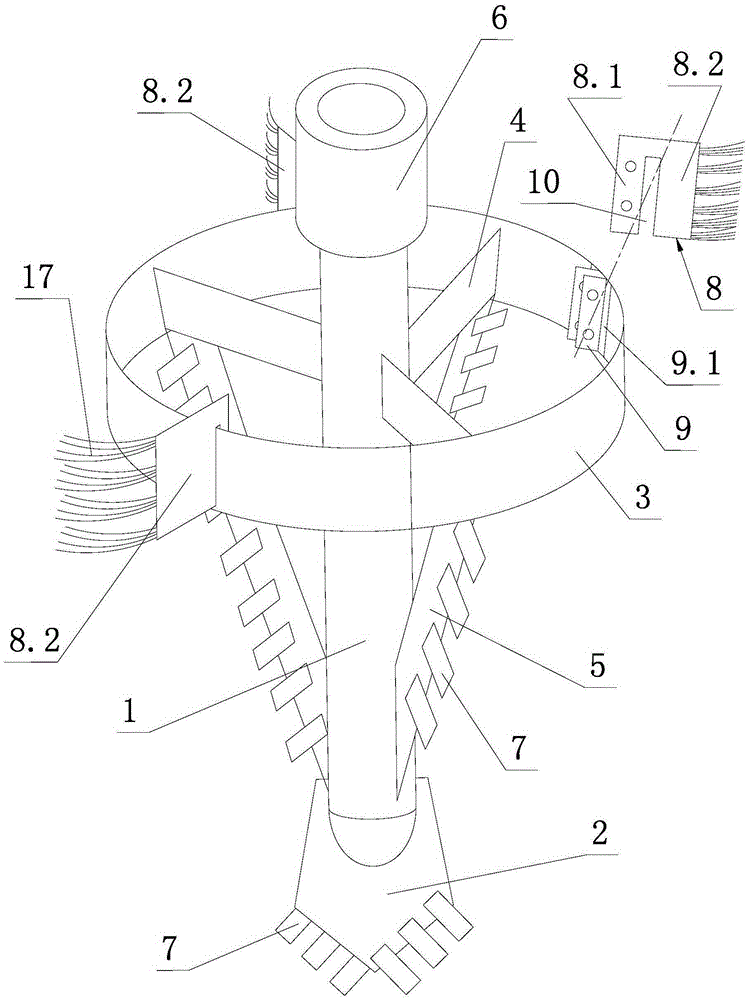

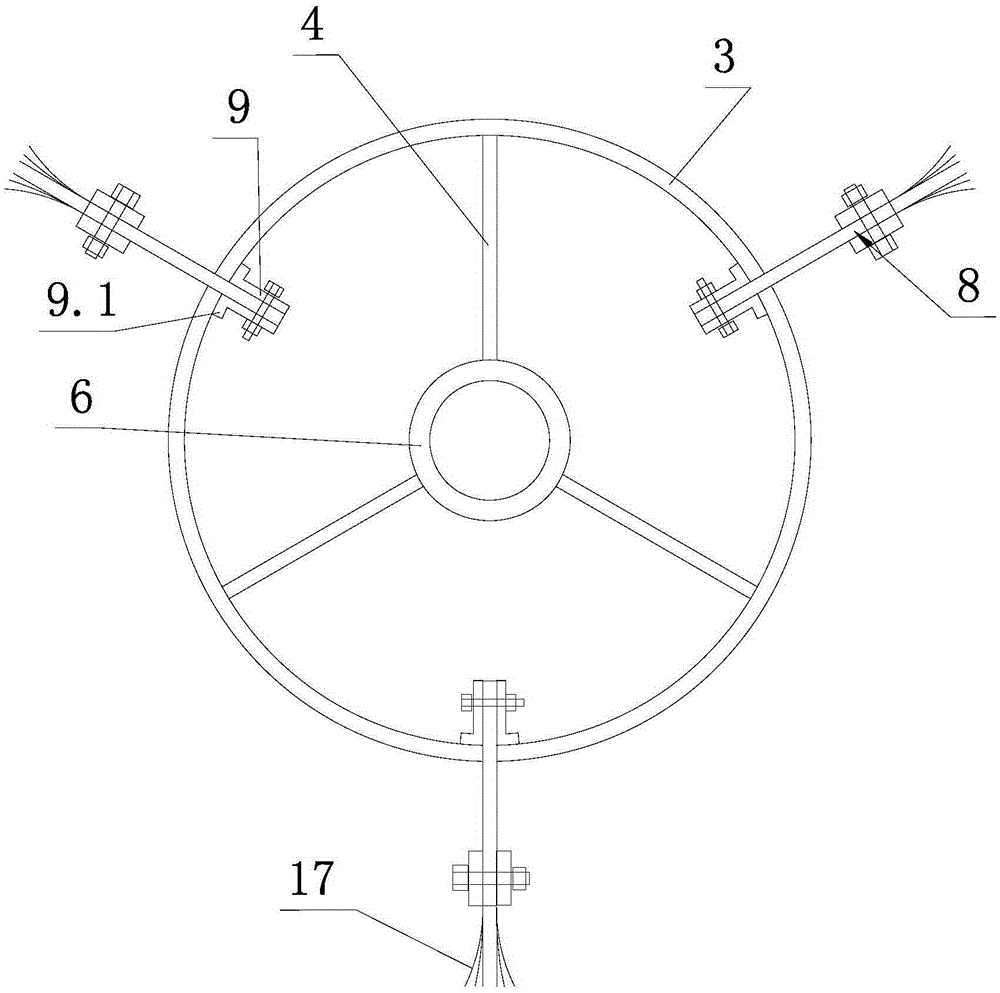

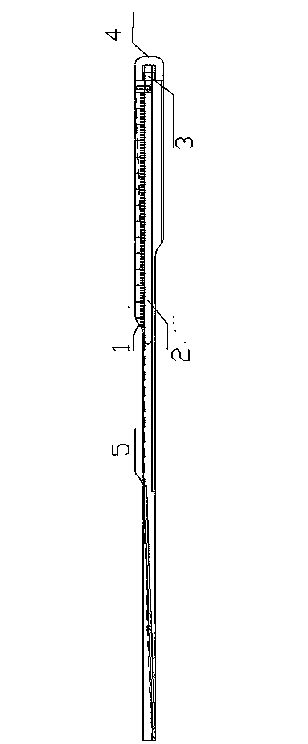

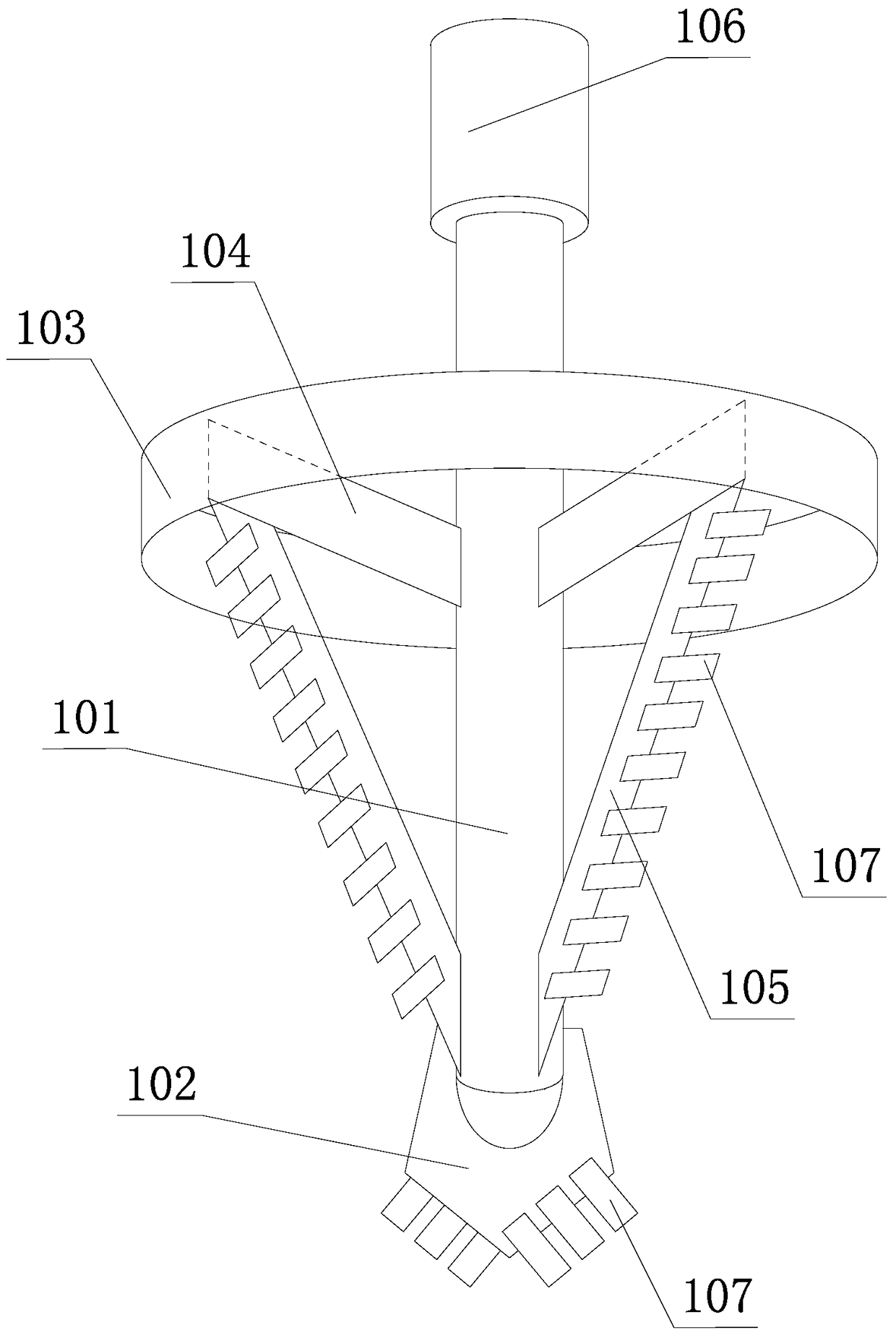

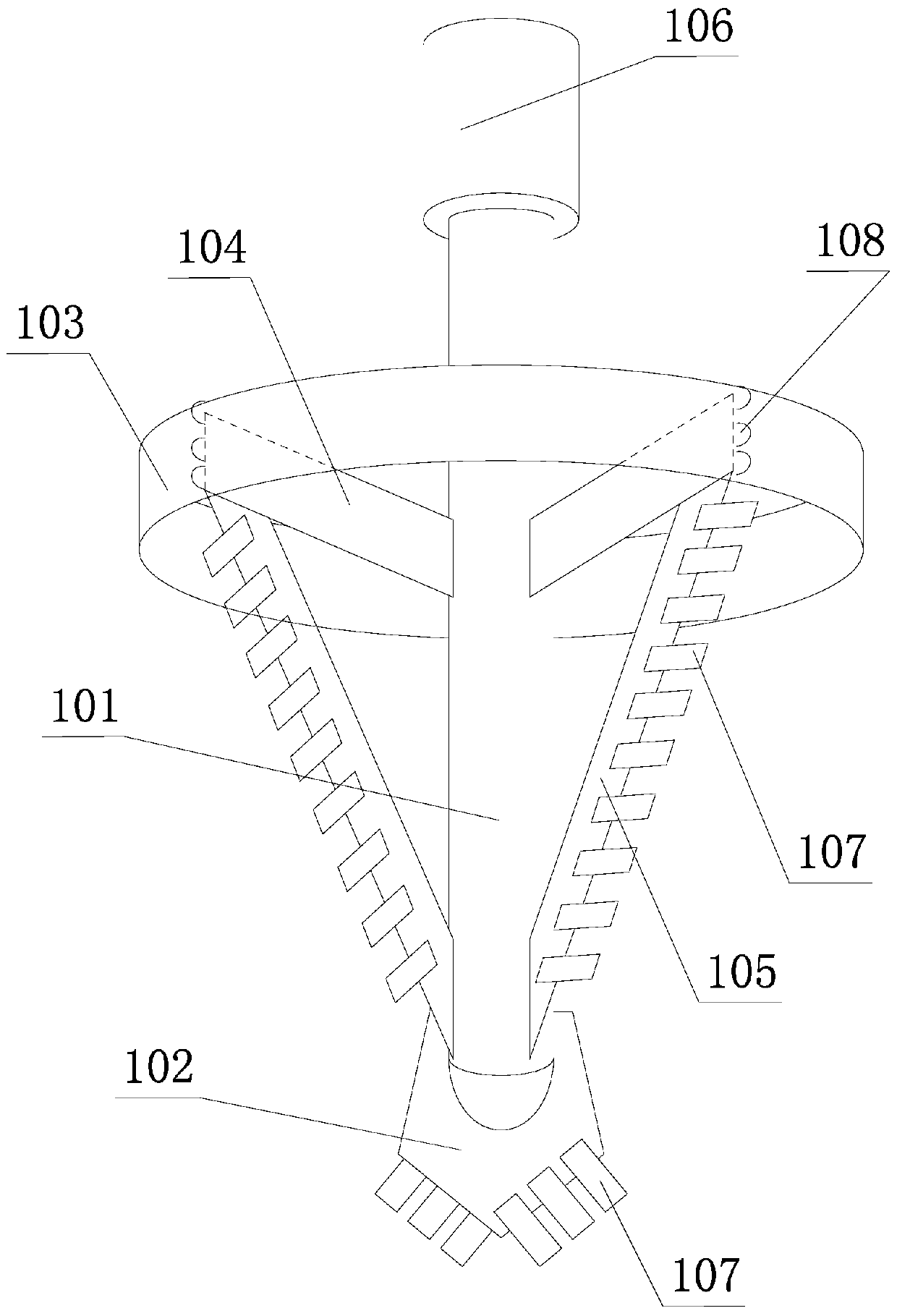

Drill bit for constructing cast-in-situ bored pile and hole forming method using same

ActiveCN105317381ALow costFast constructionEarth drilling toolsDrill bitsStructural engineeringSmall hole

The invention discloses a drill bit for constructing a cast-in-situ bored pile and a hole forming method. The drill bit is provided with a detachable mud scrapping assembly, the mud scrapping assembly comprises mud scrapping plates (8) and installing plates (9), the installing plates (9) are welded to the inner circumferential face of a check ring (3), a steel brush (14) is arranged at the outer side of each mud scrapping part (8.2), the mud scrapping plates (8) are hooked and hung on the check ring (3) through clamping grooves (10), and an installing part (8.1) of each mud scrapping plate (8) is located between two corresponding installing plates (9) in the same set and fixed to the corresponding installing plates (9) at the two sides through threaded connection. The hole forming method is characterized in that in the drilling process, the mud scrapping plates (8) are installed on the check ring (3) to drill a big hole matched with a pile casing in size, and then the mud scrapping plates (8) are dismantled to drill a small hole, wherein the size of the small hole is matched with the design size of the cast-in-situ bored pile. By means of the drill bit and the hole forming method, sandy soil between the pile casing and the pile hole can be effectively drilled away without substantially increasing time and economic cost.

Owner:浙江易通特种基础工程股份有限公司

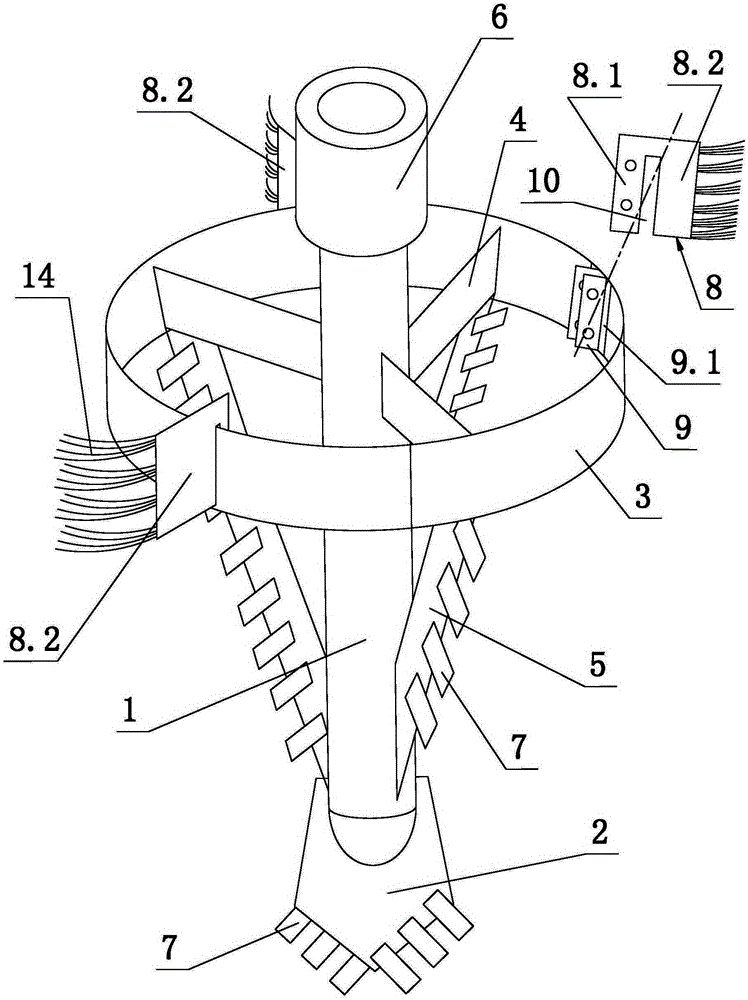

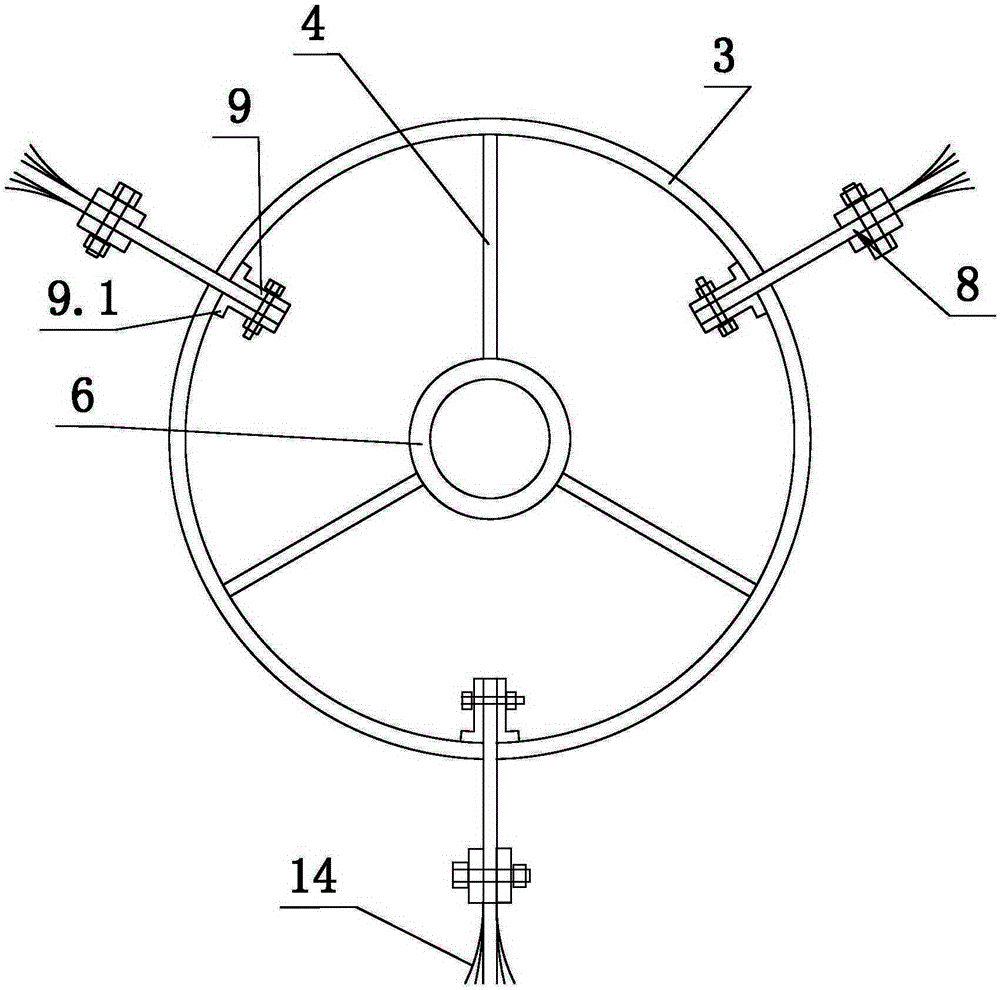

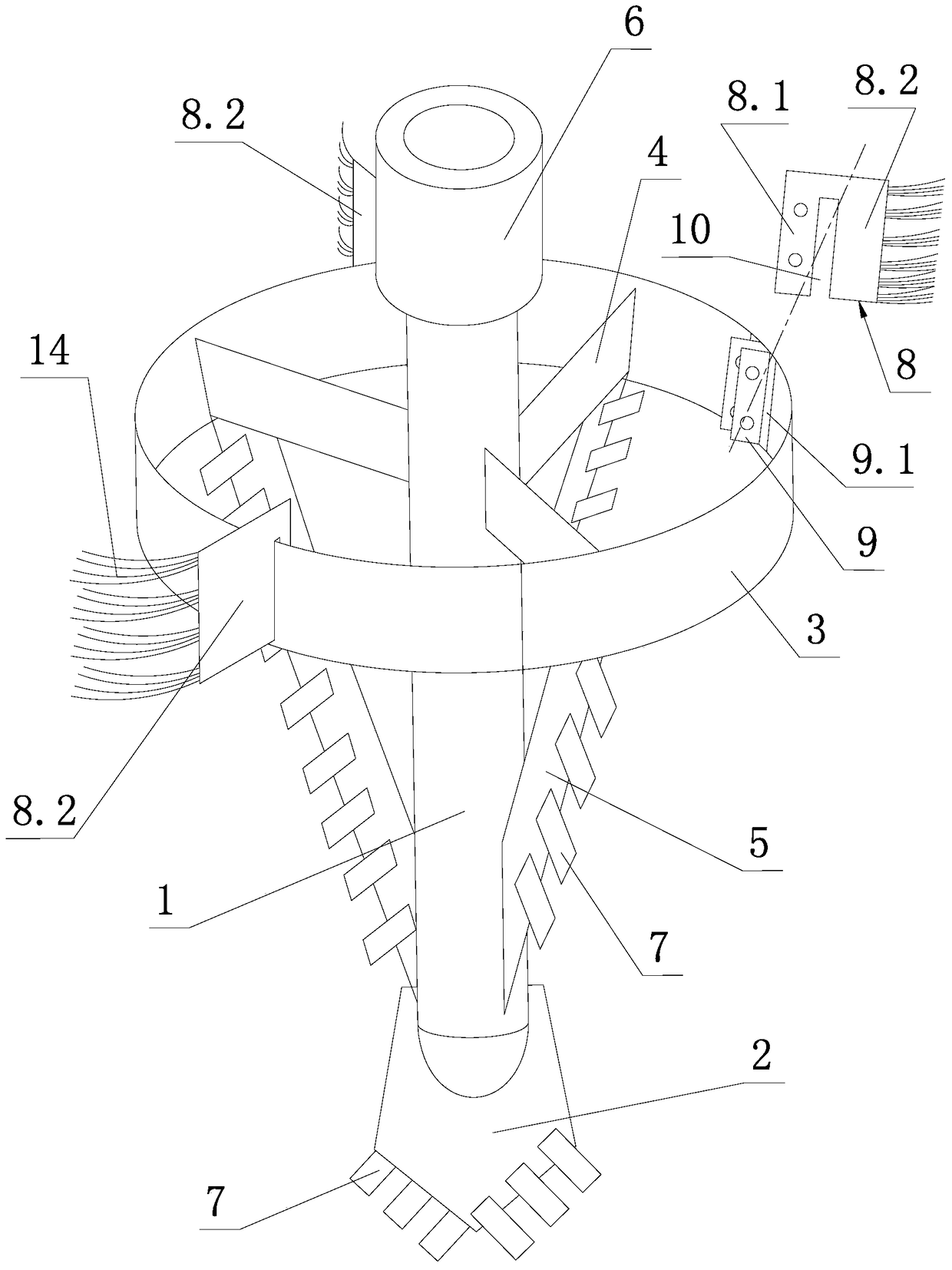

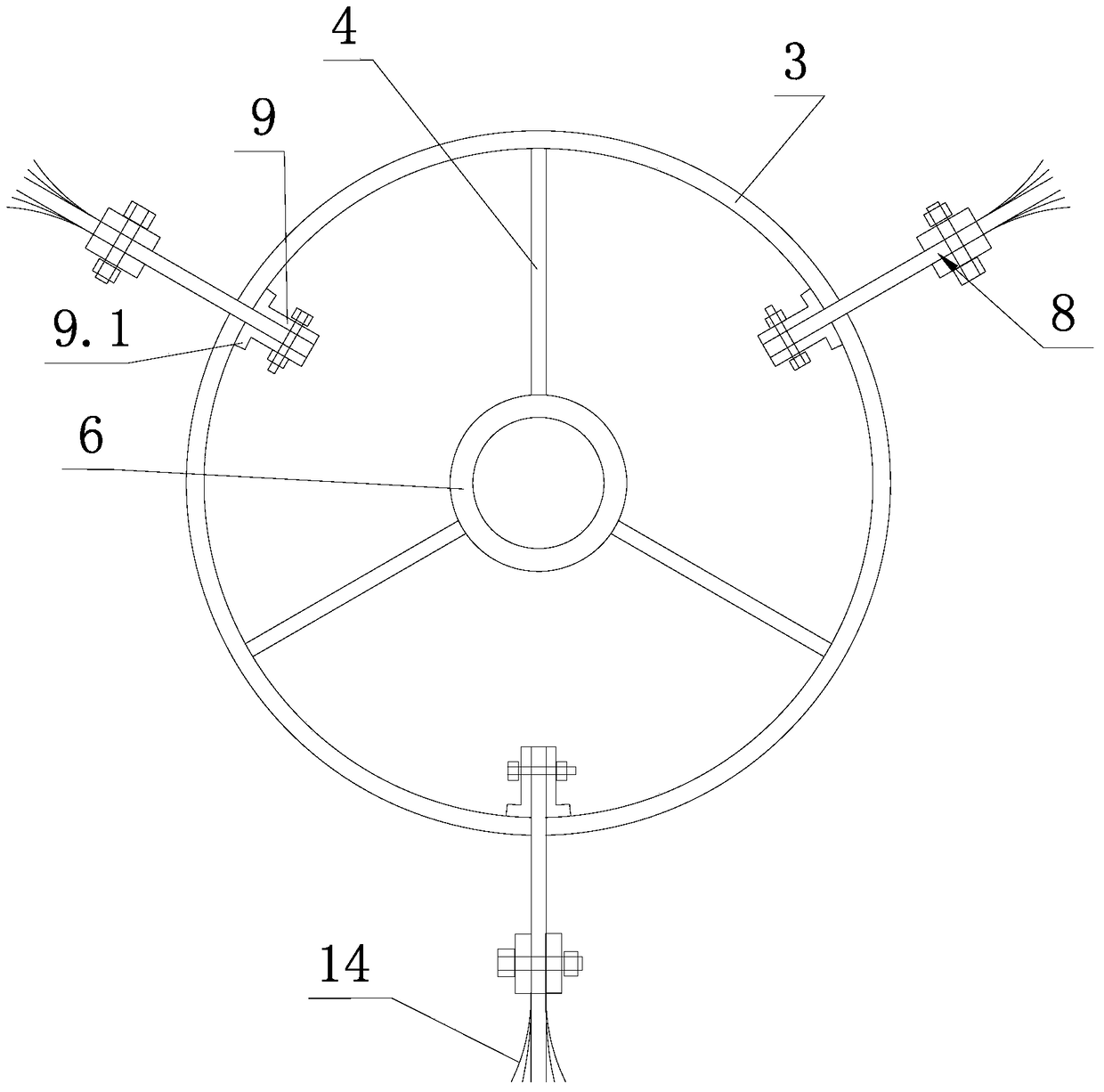

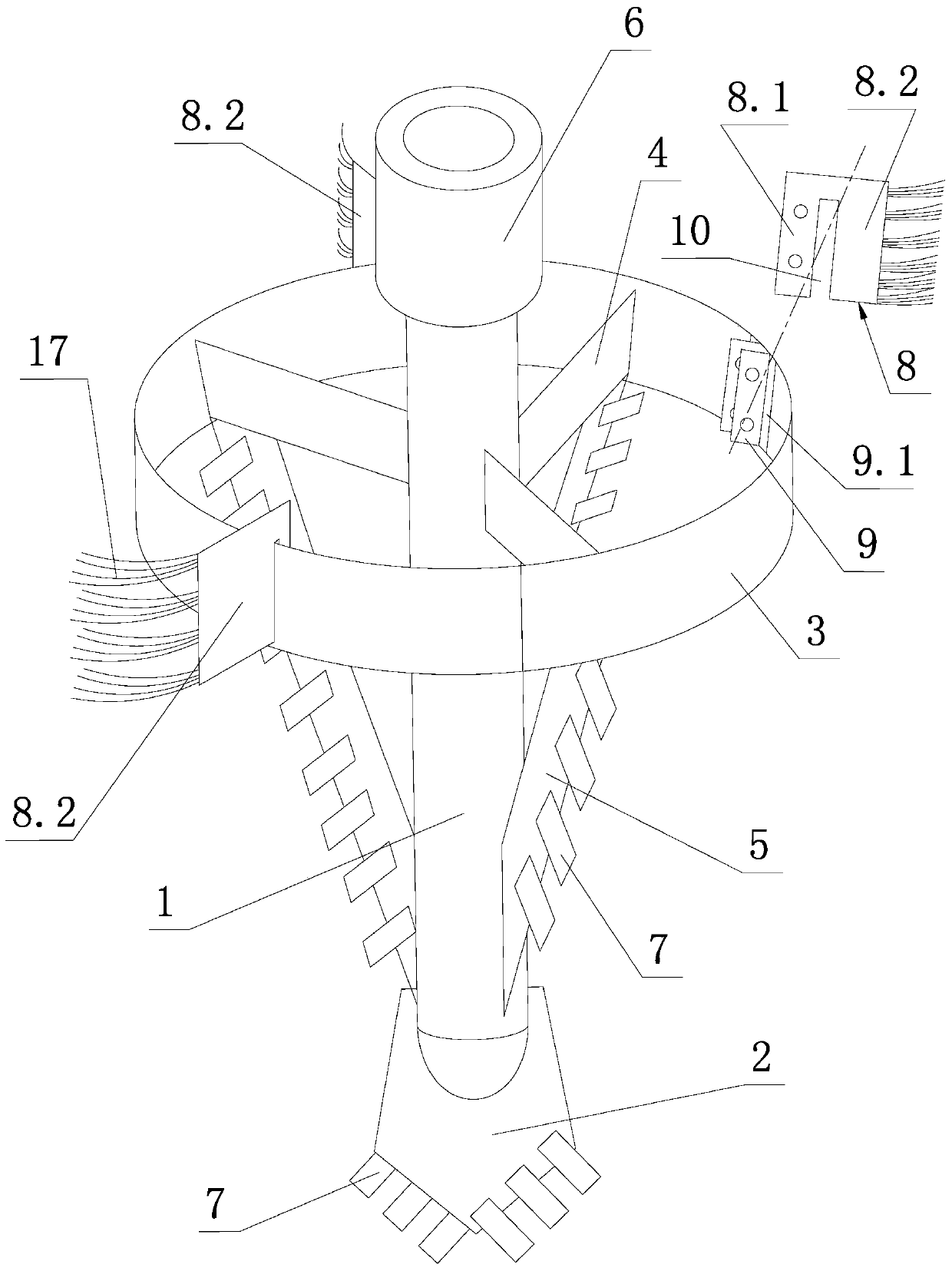

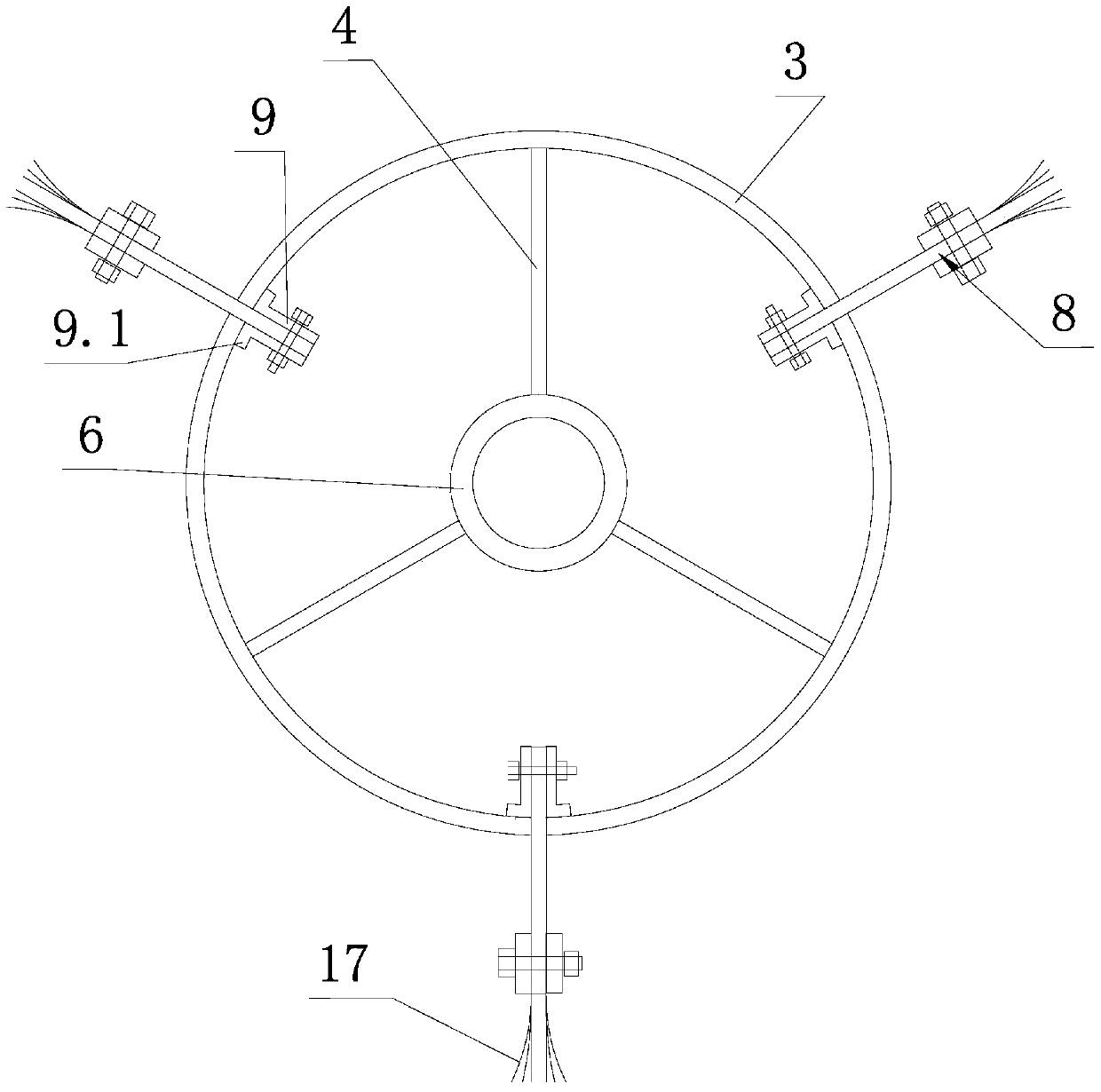

Drill bit for constructing bored piles and construction method using same

ActiveCN105317382AAvoid wear and tearLow costEarth drilling toolsDrill bitsStructural engineeringSmall hole

The invention discloses a drill bit for constructing bored piles and a construction method using the drill bit. The drill bit is provided with a mud scraping assembly and a detachable rib protecting block. The mud scraping assembly comprises a mud scraping plate (8) and installing plates (9), and the installing plates (9) are welded to the circumferential face of the inner circle of a block ring (3). A steel brush (17) is arranged on the outer side of the mud scraping plate (8). The mud scraping plate (8) is hung on the block ring (3) through a first clamping groove (10). An installing part (8.1) of the mud scraping plate (8) is located between the two installing plates (9) of the same set, and the installing part (8.1) of the mud scraping plate (8) and the installing plates (9) on the two sides are fixed in a threaded connection mode. The method is characterized in that in the drilling process, the mud scraping plate (8) is firstly installed on the block ring (3) so that a large hole with the size matched with that of a pile casing can be drilled, then the mud scraping plate (8) is taken down, and the rib protective block is installed so that a small hole with the size matched with the designed size of the bored piles can be drilled. By means of the drill bit and the construction method, sand soil between the pile casing and the pile holes can be effectively removed in a drilling mode.

Owner:浙江易通特种基础工程股份有限公司

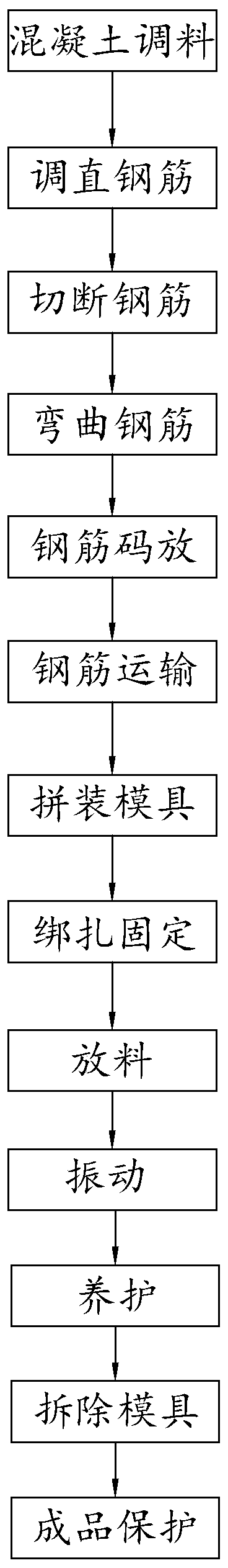

Production process for prefabricated steel bar component

InactiveCN110450262AControl performancePerformance is easy to controlCeramic shaping apparatusSurface finishHoneycomb

The invention discloses a production process for a prefabricated steel bar component, and raw materials comprise cement, lime, sand and steel bars. The advantages of the production process are: the whole construction step is simple, and the production process has the advantages of environmental protection, no pollution, and quick and labor-saving construction; after artificially controlling the curing time, the performance of the prefabricated steel bar component plates is more easily controlled; the prefabricated steel bar component plates have the advantages of high surface smoothness, highhardness, high impact strength, etc.; the prefabricated steel bar component plates are closely combined with each other to reduce the gap between each other, and the heat insulation effect is improved; and honeycomb, exposed ribs, pitted surfaces and holes in the prefabricated steel bar component plates are avoided in the whole construction process.

Owner:浙江歌山建筑科技有限公司

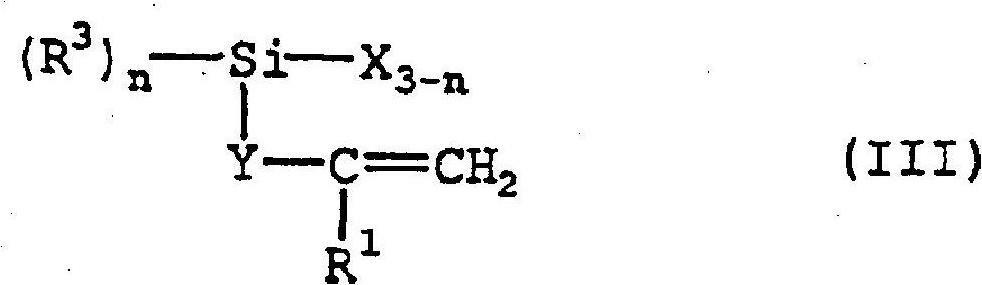

Water-based antirust and antifouling paint used on wall surface and preparation method thereof

InactiveCN102690561ASimple construction operationAnti-fouling abilityAntifouling/underwater paintsPaints with biocidesSolventEmulsion

The invention relates to a type of water-based antirust and antifouling paint used on a wall surface. The paint contains the following components in parts by weight: 20-60 parts of film forming substance, 1-10 parts of film-forming additive, 0.5-2 parts of copolymer of unsaturated monomer which contains fluoro aliphatic groups and unsaturated silane monomer, 0-5 parts of cosolvent, 0.1-1 part of corrosion inhibitor and appropriate amount of water. The invention further designs a preparation method of the paint. The water-based paint used for preventing rust and dirt on the wall surface is environment-friendly and economic; the water-based paint and common wall surface emulsion paints have the same the construction ways. The paint disclosed by the invention can prevent rust on the wall surface, has the capability of resisting stains and can reach better beautifying and decoration effects. The paint is an excellent paint which is used on the wall surface and is antirust, antifouling, environment-friendly and economic.

Owner:TIANCHANG YINHU PAINT

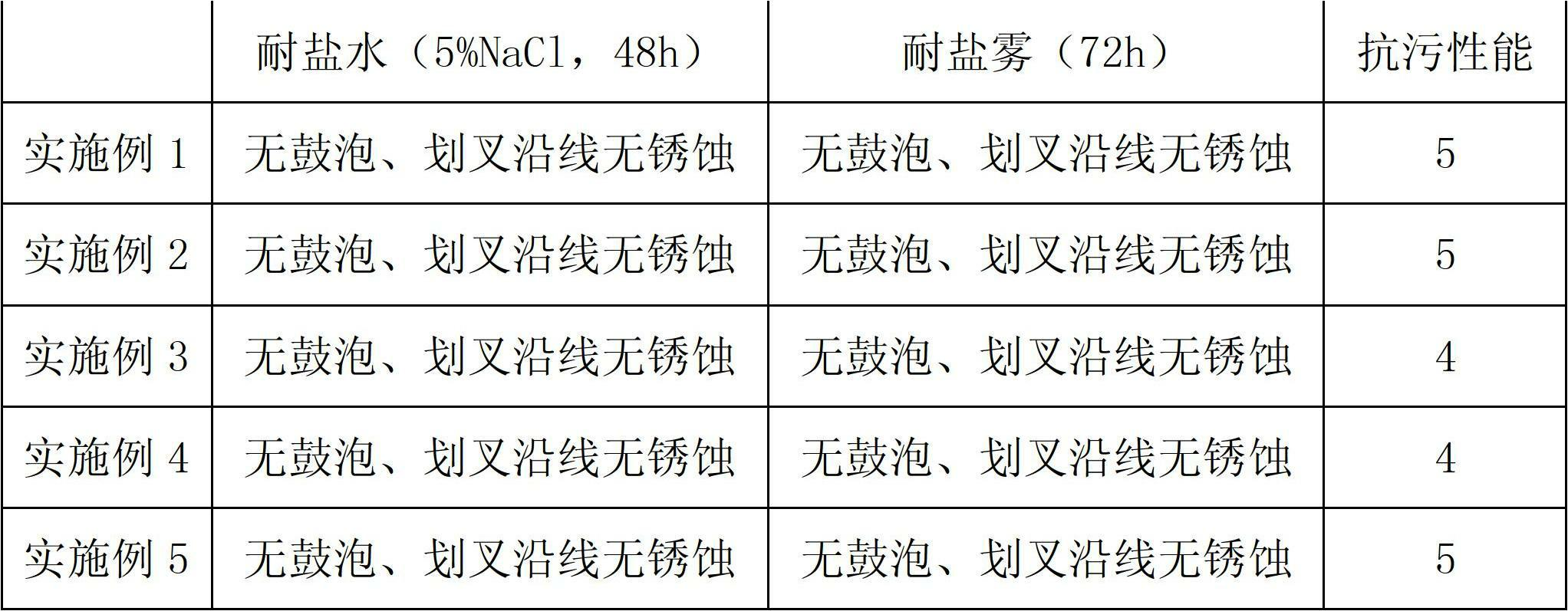

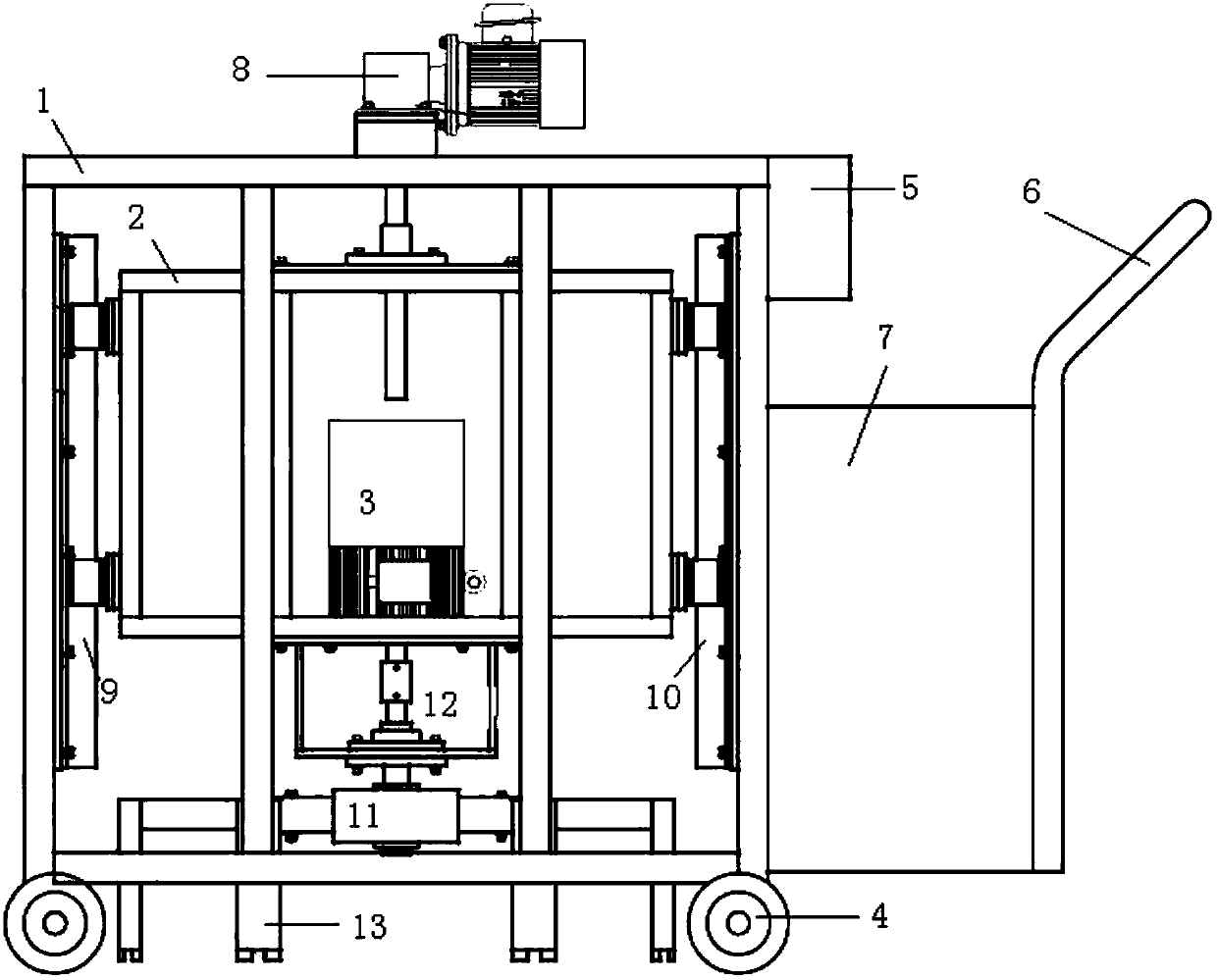

Vertical-type well cover cyclone milling machine

PendingCN107675600AImprove efficiencyConstruction time savingRoads maintainenceHandrailGenerating unit

A vertical-type well cover cyclone milling machine is composed of a cyclone milling outer frame, a cyclone milling inner frame, a rotating motor, a milling cutter head part, a lifting system, travelling systems, a control system, a handrail and a generator set. The cyclone milling outer frame and the cyclone milling inner frame are each of a rectangular frame structure, and the travelling systemsare mounted at the bottom of the cyclone milling outer frame. A platform of the generator set and the handrail are mounted on the right side of the cyclone milling outer frame. The lifting system is composed of a lifting motor, a left sliding way and a right sliding way. The milling cutter head part is connected with the rotating motor and comprises a cutting support, a connecting part and millingcutters. The control system adopts a PLC. Milling and drilling of a circular well cover hole are achieved, the trouble of multiple-time crossed destructive cutting of a common joint cutter is eliminated, the efficiency of the vertical-type well cover cyclone milling machine is higher than that of the common joint cutter, the time, labor and materials are saved during construction, and the constructed road surface is attractive, firm, durable and high in bearing capacity, and leakage and collapse are avoided.

Owner:平文福

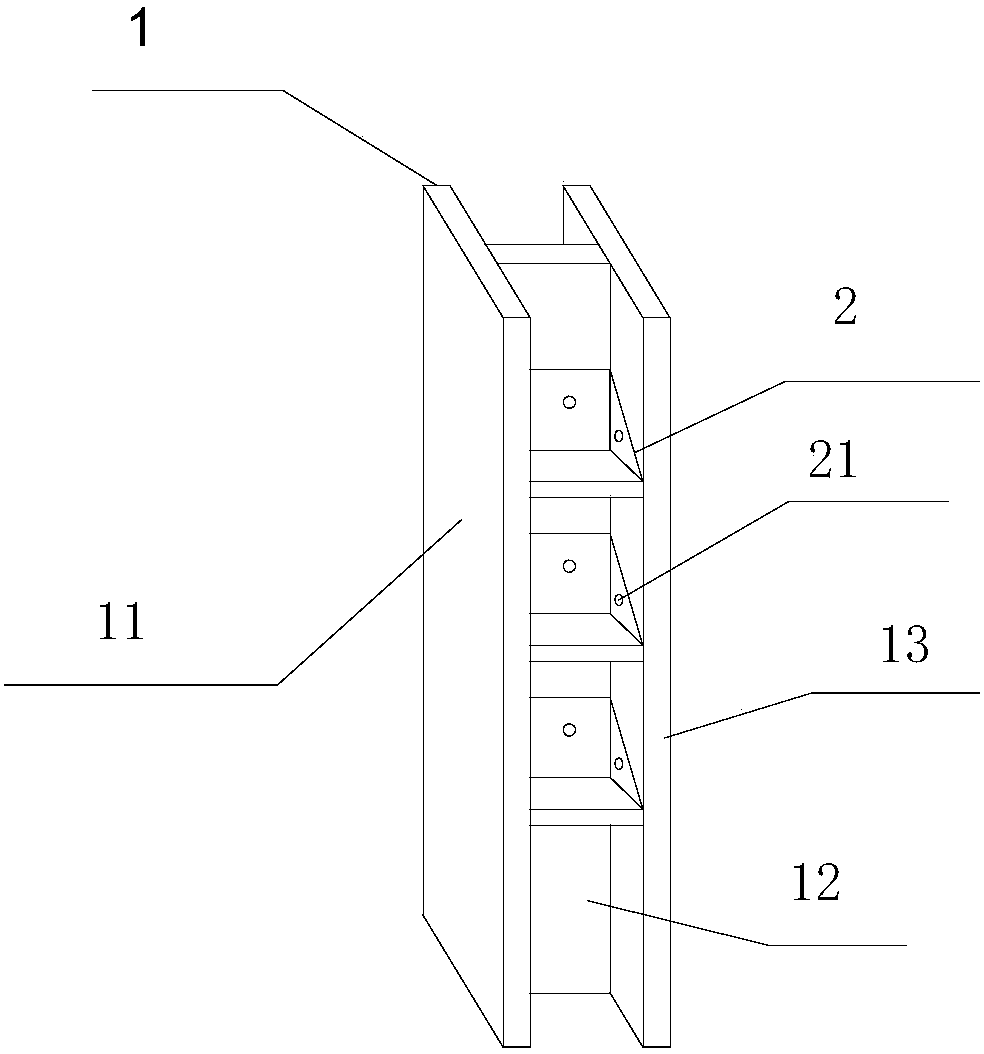

Adjustment tool for large-motor rotor and stator

InactiveCN103683760AReduce guardianshipLabor-saving constructionMechanical clearance measurementsCentering/balancing rotorsOblique planeBuilding construction

The invention relates to a large motor and particularly relates to an adjustment tool for the large motor. The adjustment tool for a large-motor rotor and stator includes a main ruler and an auxiliary rule. The main rule is hollow inside and the upper edge of the outer surface of the main ruler is provided with a scale and the side face of the main ruler is provided with an opening groove. Two walls at the inner side of the main ruler are both provided with oblique planes which oblique from inside to outside and from top to bottom. The auxiliary ruler is inserted into the main ruler and the side of the head end of the auxiliary ruler is provided with oblique planes corresponding to the oblique planes in the main ruler. A slide shaft is arranged at the starting point positions of the oblique planes of the auxiliary ruler. The tail end of the auxiliary ruler is provided with a slide block which is inserted into the opening groove in the surface of the main ruler. The adjustment tool is capable of reducing effectively construction personnel, improving device installation efficiency and improving effectively installation precision.

Owner:CHINA MCC20 GRP CORP

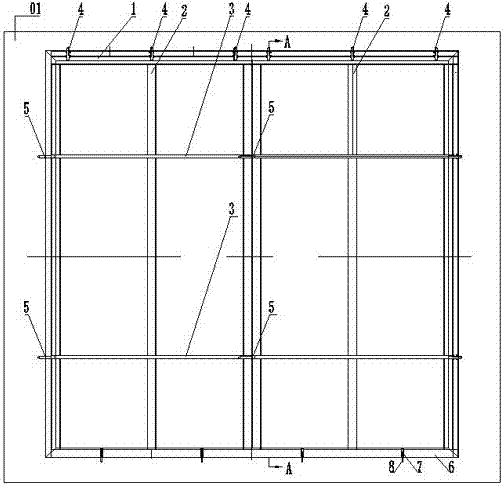

Constructional engineering construction formwork device

PendingCN112523492ALabor-saving constructionThe construction formwork device is labor-saving in useAuxillary members of forms/shuttering/falseworksForming/stuttering elementsThreaded pipeArchitectural engineering

The invention discloses a constructional engineering construction formwork device, and relates to the field of building structures. The constructional engineering construction formwork device comprises a heavy formwork and a light formwork which are provided with lock catches; the heavy formwork is provided with a threaded pipe; the threaded pipe is internally provided with a threaded rod; the threaded rod is provided with a support plate; the heavy formwork is provided with two support frames; and the support frames are provided with rollers. The constructional engineering construction formwork device is very convenient to assemble and disassemble, labor is saved during construction, the use stability is good, and the building construction efficiency is improved.

Owner:WUHAN UNIV OF SCI & TECH

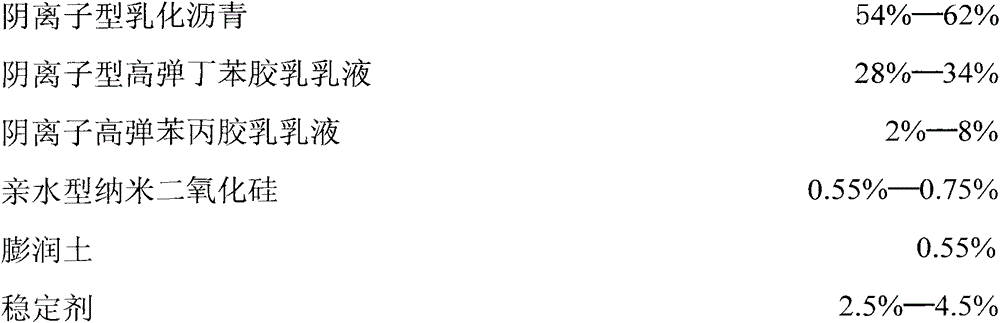

A spraying quick-setting liquid rubber waterproof coating and its production method

ActiveCN104099022BHighlight substantiveSignificant progressConjugated diene hydrocarbon coatingsChloropene polymer coatingsDemulsifierSelf-healing

The invention discloses a spraying quick-setting liquid rubber waterproof coating, which includes three components, A, B and C. The A component is a main agent solution of a waterproof material, and the B component is a catalyst and a demulsifier solution. The C component mentioned is a reinforcing fiber solution. The manufacturing method of the waterproof coating includes: the preparation of the A component, the B component and the C component respectively, and then the three components are sprayed out through independent feeding and discharging systems, and the atomized two components A and B are sprayed out. The C components meet, mix and react in the air. After landing, they are rapidly formed, and the reaction water is precipitated. After special rolling, the AB mixture and the C component reinforcing fibers are bonded together to form an integral seamless fiber-reinforced membrane. The obvious advantages of the invention are: fast film formation, spraying for 4 seconds; excellent adhesion; high elastic self-healing; high elongation, elongation above 600%; ; And strong corrosion resistance and high and low temperature resistance.

Owner:北京世纪洪雨科技有限公司

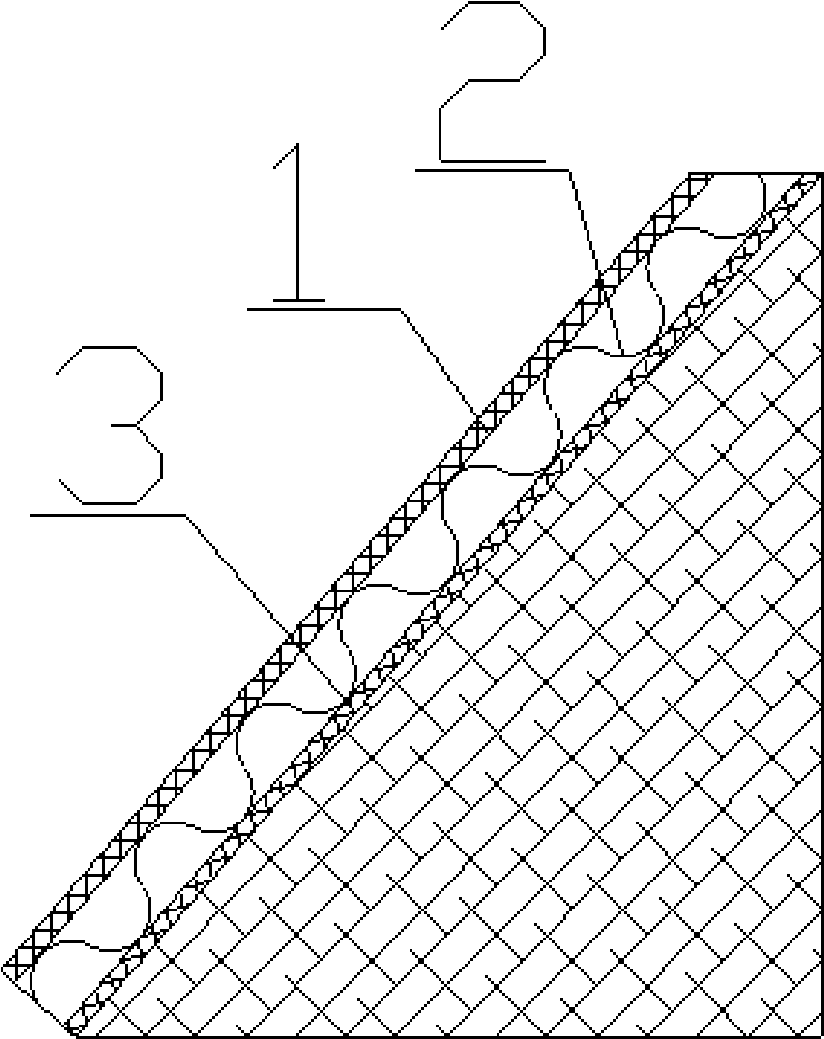

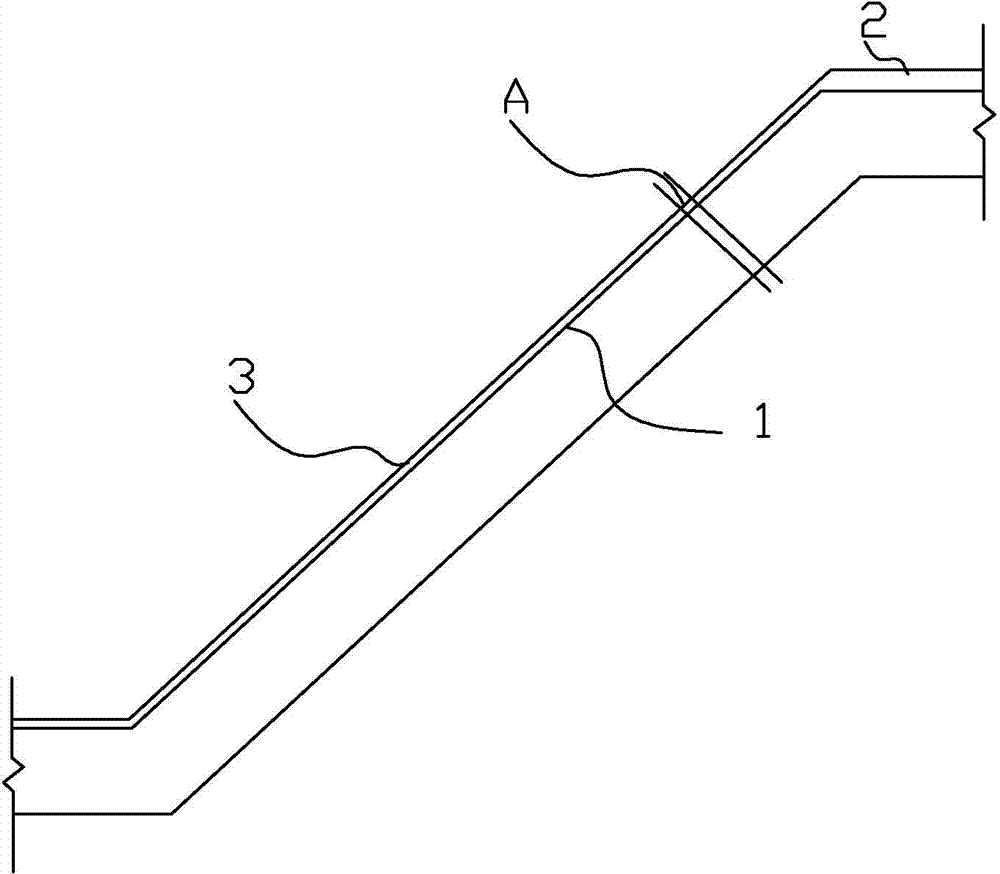

Construction method of protection layer of foundation pit oblique plane waterproof layer

InactiveCN103882890AEasy constructionSecondary transfer is convenientProtective foundationEngineeringGalvanization

The invention discloses a construction method of a protection layer of a foundation pit oblique plane waterproof layer. The method is adopted on the foundation pit waterproof oblique plane with the angle being larger than or equal to 45 degrees, and conventional fine aggregate concrete is replaced by galvanized iron sheets to serve as the protection layer of the waterproof layer. The method specifically comprises the first step of preparing materials for the protection layer, wherein a metal skin with good extensibility is customized according to the area of the constructed foundation pit waterproof oblique plane to serve as the protection layer; the second step of pasting the protection layer on the waterproof layer oblique plane, wherein one face of the protection layer is coated with a binding agent and the oblique plane waterproof layer is externally paved with the protection layer; the third step of clipping and edge repairing, wherein clipping is carried out according to the actual situation on the spot, and a little galvanized sheet iron is used for repairing the edges at the junction of a thin part. The metal skin with good extensibility serves as the protection layer and is galvanized sheets with the thickness ranging from 0.35 mm to 0.5 mm, the binding agent coated on the back face of the protection layer is 502 glue, and the metal skin serving as the protection layer can be formed by splicing the galvanized sheets and binding the galvanized sheets through a seal adhesive belt with the width ranging from 50 mm to 70 mm. The construction method is convenient to apply, time and labor are saved, and the protection effect for the waterproof layer is good.

Owner:广西建工第五建筑工程集团有限公司

Cavern-shaped molding board for salt treatment house roof

InactiveCN101871243ASafe installationEasy constructionCeilingsBathing devicesGlass fiberPolymer science

The invention relates to a cavern-shaped molding board for a salt treatment house roof, which comprises a wire-mesh framework, a projection, polyurethane expanded polystyrene or mortar, bond and salt powder, wherein the wire-mesh framework is provided with the projection, the projection is provided with a layer of polyurethane expanded polystyrene or mortar, and a layer of bond and salt powder is sequentially arranged above the polyurethane expanded polystyrene or mortar. The wire-mesh framework is of a square shape, a rectangular shape, a circular shape, an ellipsoid shape or a triangular shape. The projection adopts the wire-mesh material or the molded glass fiber reinforced fabric. The projection is formed by a plurality of centrum with different sizes or raised bodies with different sizes. The materials adopted by the molding board are toxic free and harmless. The wire-mesh framework, the polyurethane expanded polystyrene and the sand are of light materials. The molding board is very safe to install on the roof, is convenient to construct, and saves time and labor. A plurality of molding boards can be joined to form the roof so as to authentically reflect the cavern effect, so people can have a rest in silence just like entering the natural cavern, and can breath freely so as to realize the best treatment effect.

Owner:天津港保税区佳辰国际贸易有限公司

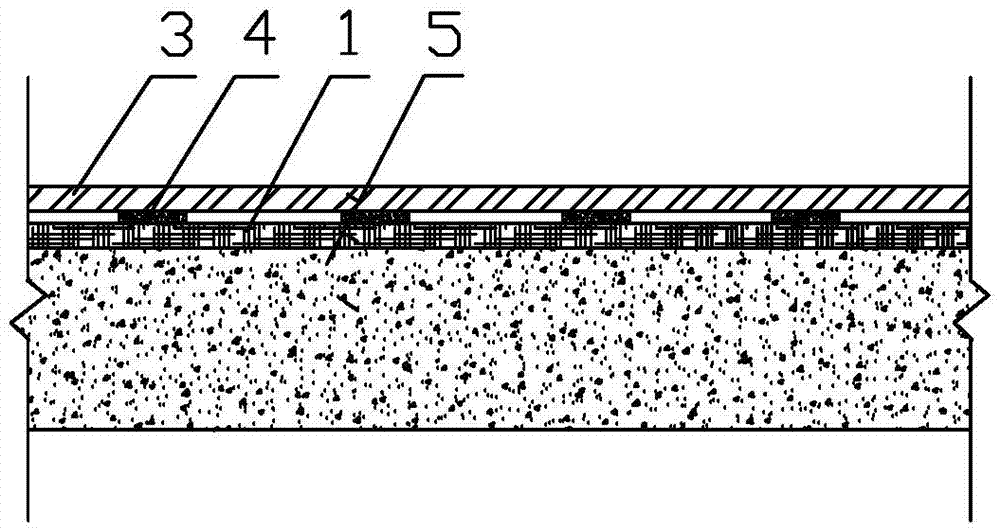

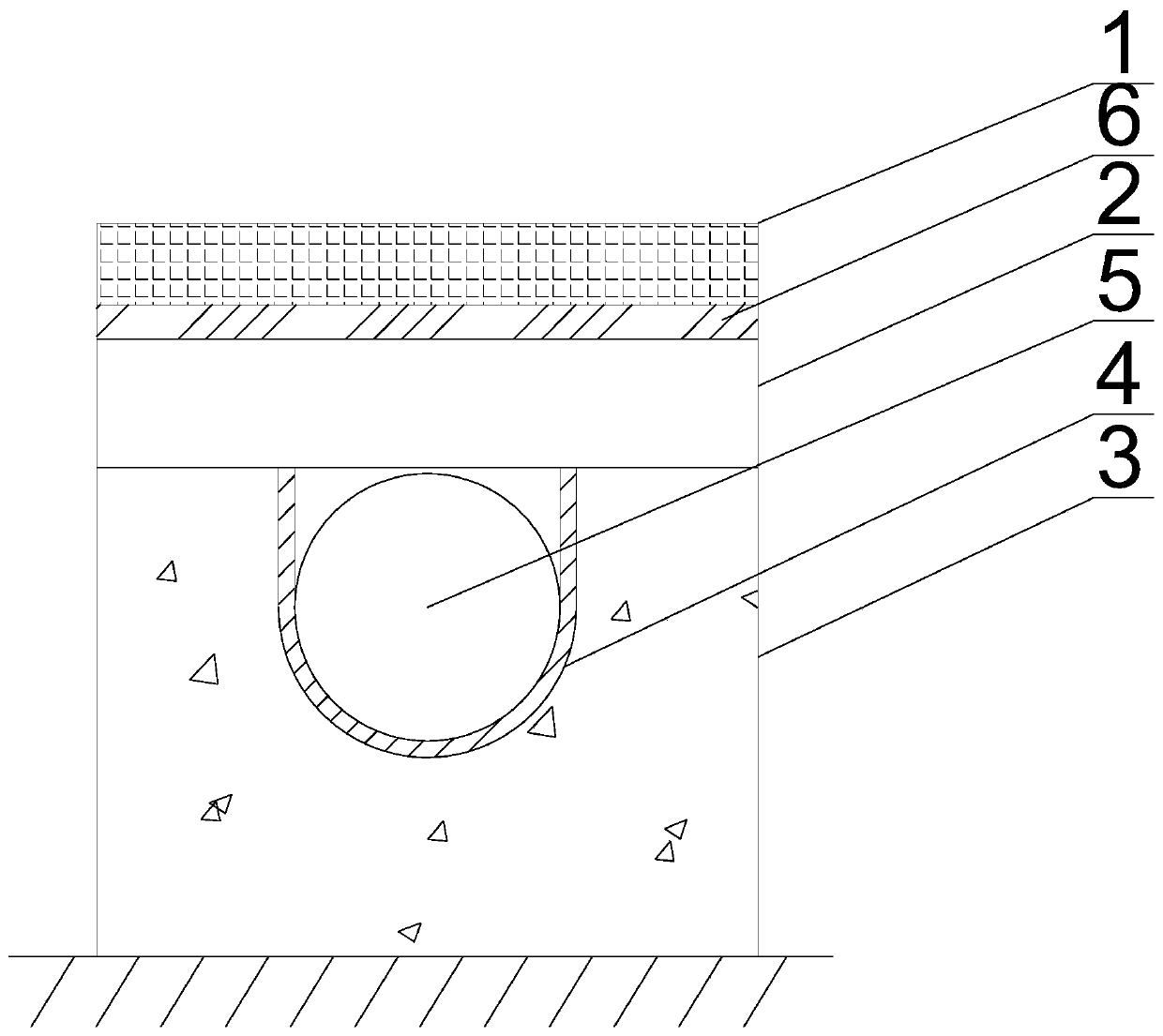

Thin type floor heating system mounting structure

InactiveCN110243004AImprove heating efficiencyReduce consumptionLighting and heating apparatusSpace heating and ventilation detailsEngineeringIncrease temperature

The invention discloses a thin type floor heating system mounting structure, and relates to the technical field of floor heating system mounting structures. The thin type floor heating system mounting structure comprises a floor decoration layer which is manufactured through a thin ceramic board, a heat dissipating plate which is connected through a special adhering agent for heating, and a heat preserving layer. With the adoption of the thin type floor heating system mounting structure, more than 50% of thickness of the constructed surface can be saved, and the good effect of 'decreasing three and adding one' is achieved; decreasing three is namely decreasing the energy consumption of a floor heating system, reducing the loss of housing story, and reducing the overall construction period; and adding one is adding the temperature increasing temperature of the floor heating system.

Owner:四川赛特威斯科技有限公司

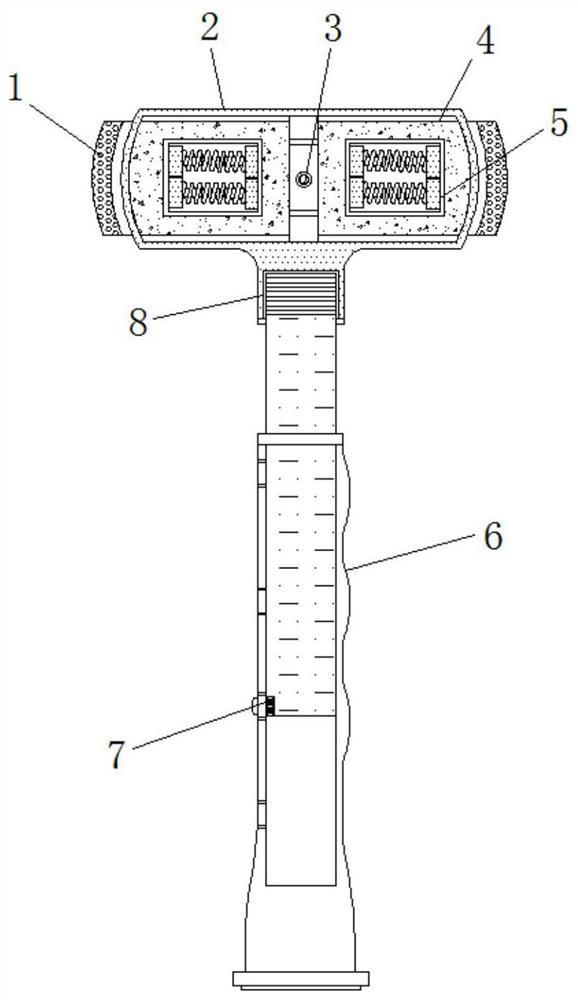

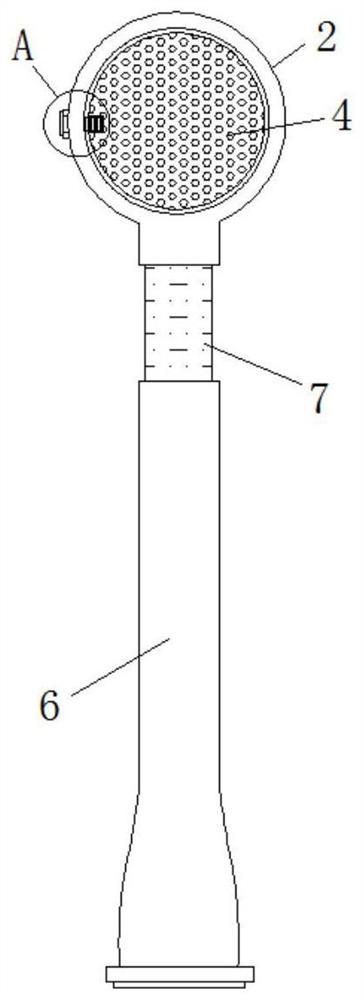

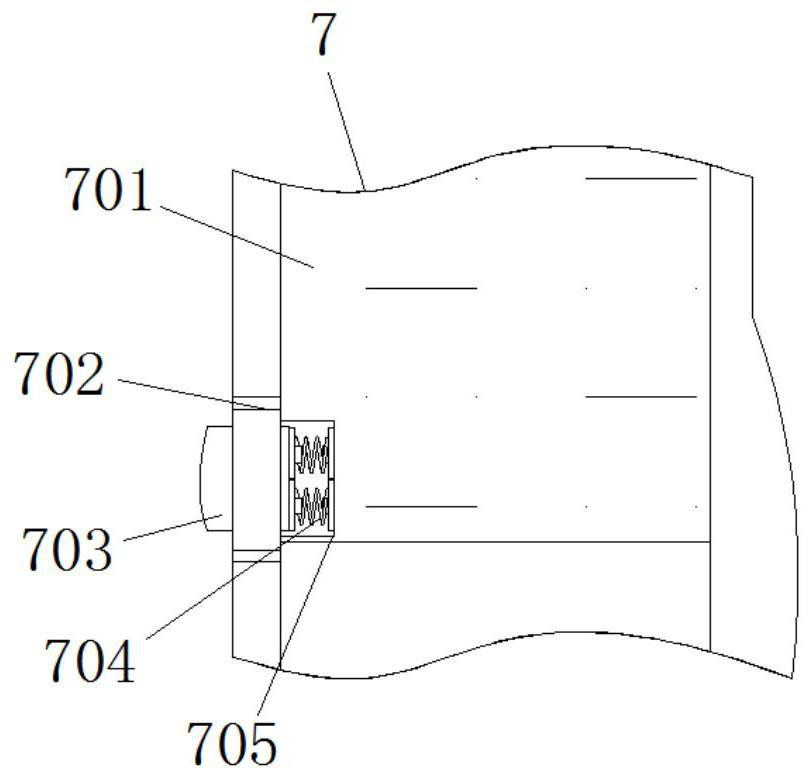

Rubber hammer for power construction

ActiveCN111618794AReasonable structureReduce volumeHand hammersMetal-working hand toolsHand partsClassical mechanics

The invention discloses a rubber hammer for power construction. The rubber hammer comprises a fixed ring, a rubber hammer body and a rod. A lifting structure is movably connected in the rod, and the bottom end of the lifting structure is movably connected with a mounting groove. The fixed ring is arranged at the top end of the mounting groove, and the rubber hammer body is connected in the fixed ring in a clamped manner. Shock absorption structures are arranged in the rubber hammer body and each comprise a cavity, connecting blocks, a first buffer spring and a second buffer spring. The shock absorption structures are arranged in the rubber hammer body, and during use, when the rubber hammer body is in contact with a contact object to apply force, the inner shock absorption structures can bear force to achieve buffering; and the cavities are arranged in the rubber hammer body, the first buffer springs and the second buffer springs are arranged in the cavities, the interiors of the cavities are supported and filled, when the rubber hammer body bears force, the inner buffer springs bear force to achieve internal digestion, the vibration feeling of the hands is reduced, and the rubberhammer is more comfortable to use and better in shock absorption and buffer effect.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

Convenient foundation pit supporting frame and supporting method thereof

PendingCN108505526ASimple structureIncrease production capacityExcavationsRight triangleArchitectural engineering

The invention provides a convenient foundation pit supporting frame and a supporting method thereof. The convenient foundation pit supporting frame comprises a supporting frame body and an embedded part, wherein the supporting frame body is of an integral structure with the I-shaped cross section and comprises a left side plate, a web and a right side plate; the left side plate and the right sideplate are respectively and fixedly arranged at the two sides of the web; a plurality of side plate connecting parts are uniformly distributed on the inner walls of the left side plate and the right side plate; a plurality of web connecting parts are uniformly distributed on the web; the web connecting parts and the side plate connecting parts are identical in height; the embedded part is of a triangular prism structure with a right angled triangle cross section; and fixed parts connected to the web connecting parts and the side plate connecting parts are arranged on the three right angle surfaces of the embedded part. The convenient foundation pit supporting frame and the supporting method thereof have the beneficial effects that the convenient foundation pit supporting frame is simple instructure, can be prefabricated in advance, is convenient to produce and transport, causes the site construction to be time-saving and labor-saving, facilitates the construction of workers, meanwhilefacilitates the fallow-up disassembly work and greatly improves construction efficiency.

Owner:TIANJIN JIANCHENGJIYE GRP

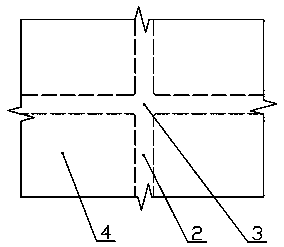

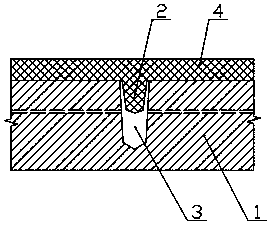

A construction method for ground structure applied to soft soil foundation

ActiveCN106087944BImprove bearing capacityTime saving during constructionSoil preservationReinforced concreteRebar

The invention provides a ground structure applied to a soft soil foundation and a construction method of the ground structure. The ground structure comprises a lower supporting rib, an intersection rib and a ground layer, wherein the lower supporting rib and the intersection rib are casted in the soft soil foundation, the ground layer is casted on the surface of the soft soil foundation, and the lower supporting rib, the intersection rib and the ground layer are of a plain concrete structure or reinforced concrete structure integrally casted and molded; and the construction method comprises the steps that the ground of the soft soil foundation is leveled, and a net-shaped groove is formed in the leveled ground; concrete is casted in the net-shaped groove and the ground; or reinforcing steel bars are arranged in the net-shaped groove and on the ground, and then, concrete is casted, so that the ground structure with the lower supporting rib, the intersection rib and the ground layer is formed; and the ground structure has the large bearing force, time and labor are saved in the construction process, the construction cost is low, and the civilized and environment-friendly construction requirement is met.

Owner:福州市第三建筑工程公司

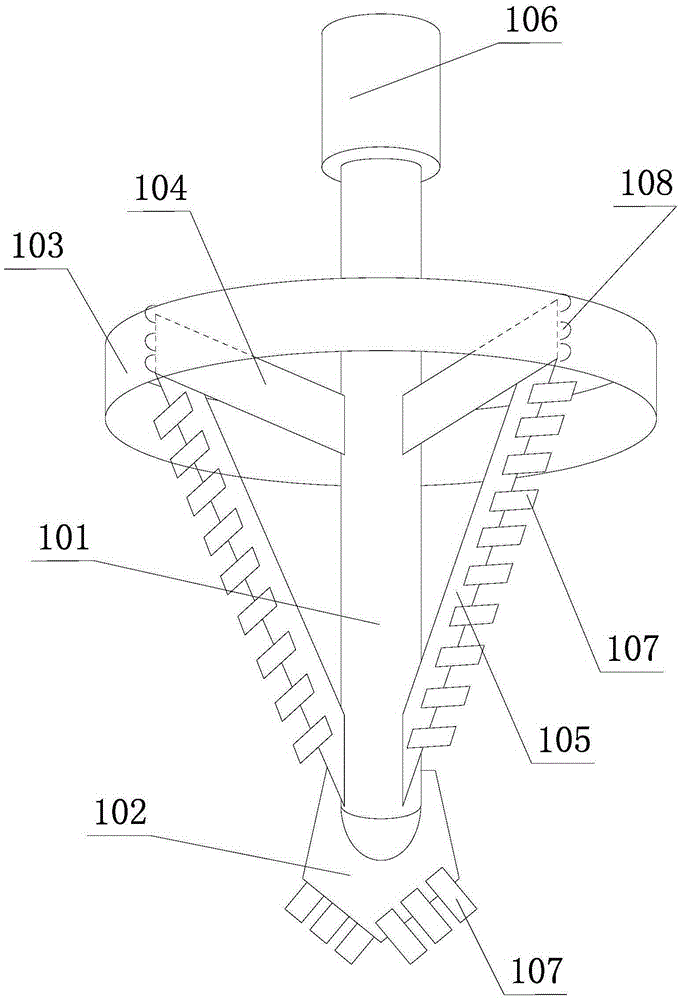

Drill bit for constructing bored pile and hole forming method using the drill bit

ActiveCN105317381BLow costFast constructionEarth drilling toolsDrill bitsStructural engineeringCost (economic)

The invention discloses a drill bit for constructing a cast-in-situ bored pile and a hole forming method. The drill bit is provided with a detachable mud scrapping assembly, the mud scrapping assembly comprises mud scrapping plates (8) and installing plates (9), the installing plates (9) are welded to the inner circumferential face of a check ring (3), a steel brush (14) is arranged at the outer side of each mud scrapping part (8.2), the mud scrapping plates (8) are hooked and hung on the check ring (3) through clamping grooves (10), and an installing part (8.1) of each mud scrapping plate (8) is located between two corresponding installing plates (9) in the same set and fixed to the corresponding installing plates (9) at the two sides through threaded connection. The hole forming method is characterized in that in the drilling process, the mud scrapping plates (8) are installed on the check ring (3) to drill a big hole matched with a pile casing in size, and then the mud scrapping plates (8) are dismantled to drill a small hole, wherein the size of the small hole is matched with the design size of the cast-in-situ bored pile. By means of the drill bit and the hole forming method, sandy soil between the pile casing and the pile hole can be effectively drilled away without substantially increasing time and economic cost.

Owner:浙江易通特种基础工程股份有限公司

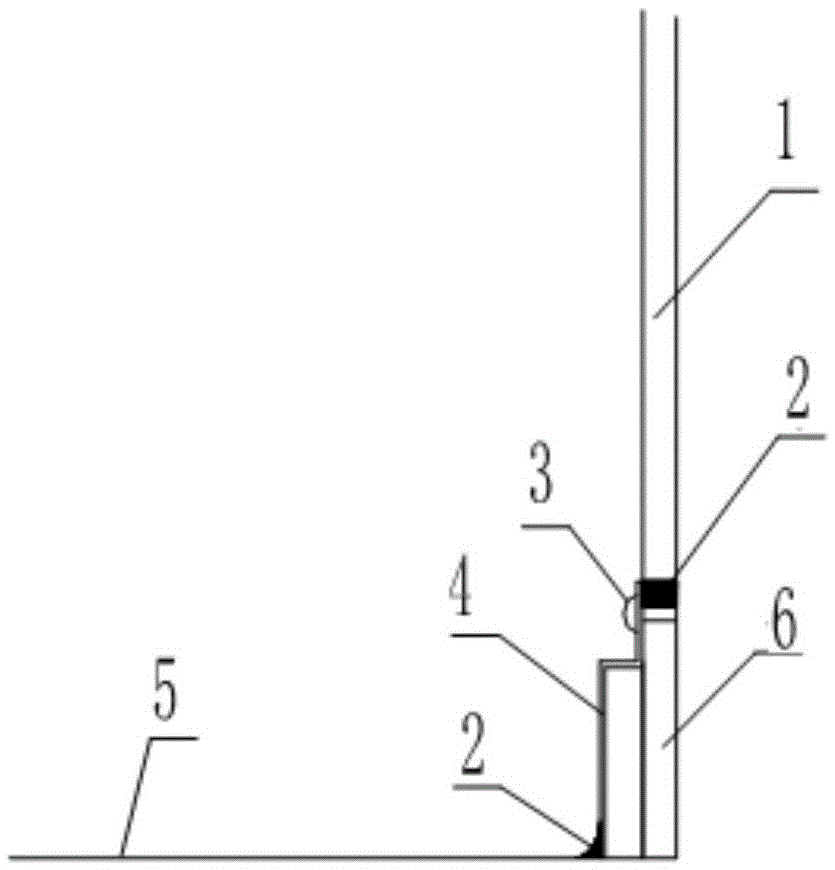

Novel stainless steel skirting construction method used in color steel plate wall

InactiveCN106760413AThe visual effect is generousConstruction time savingBuilding constructionsSteel platesMetallurgy

The invention discloses a novel stainless steel skirting construction method used in a color steel plate wall. The method comprises the first step of manufacturing stainless steel skirting lines; the second step of delivering the manufactured stainless steel skirting lines to a construction site, and connecting the stainless steel skirting lines with the color steel plate wall through rivets; the third step of filling concave joints of the color steel plate wall; the fourth step of sealing and beautifying the joint of the color steel plate wall and the ground and the concave joints of the color steel plate wall; the fifth step of conducting beautifying processing in the later period. According to the novel stainless steel skirting construction method used in the color steel plate wall, the stainless steel skirting lines can be better combined with the color steel plate wall compared with traditional skirting lines, and the combination is more decent and cleaner in visual effect compared with the traditional skirting lines. As metal skirting lines, the stainless steel skirting lines can be more harmoniously jointed with the color steel plate wall compared with the traditional skirting lines, and more time and labor through a method of rivet connection than through a traditional skirting line construction method.

Owner:MCC TIANGONG GROUP

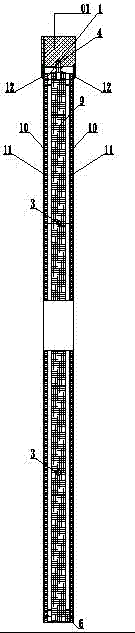

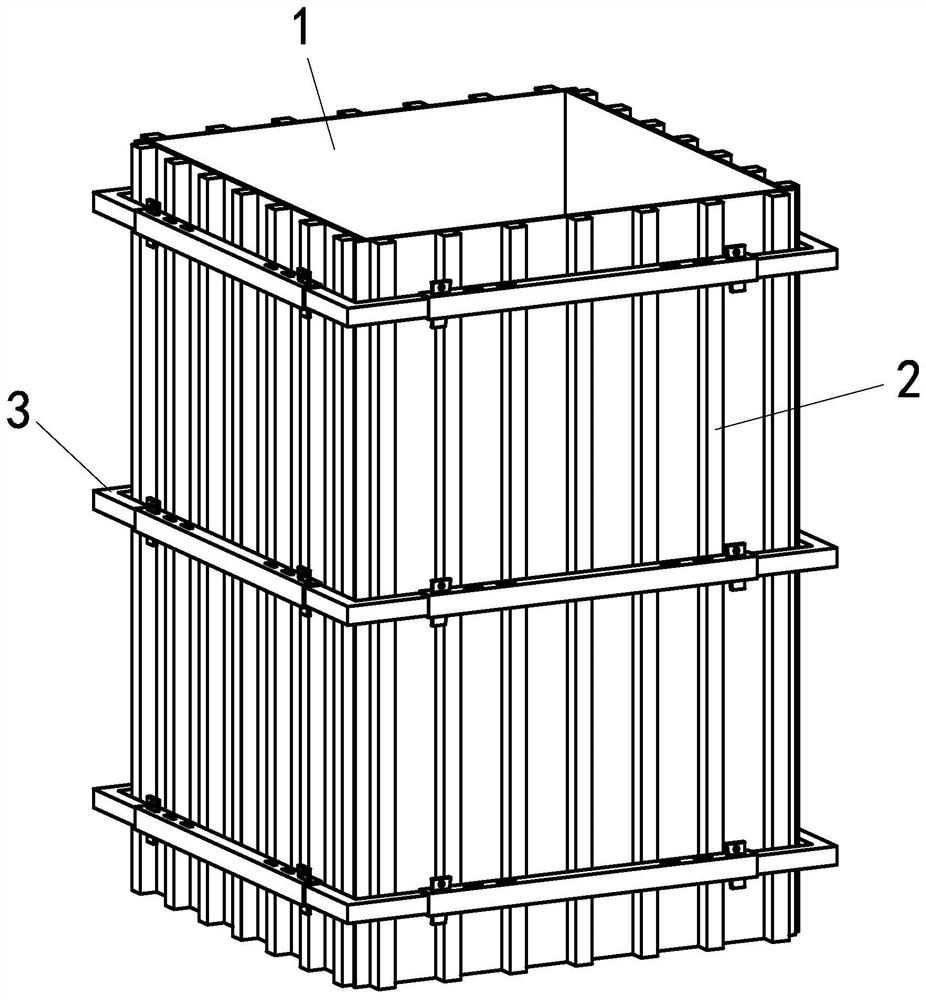

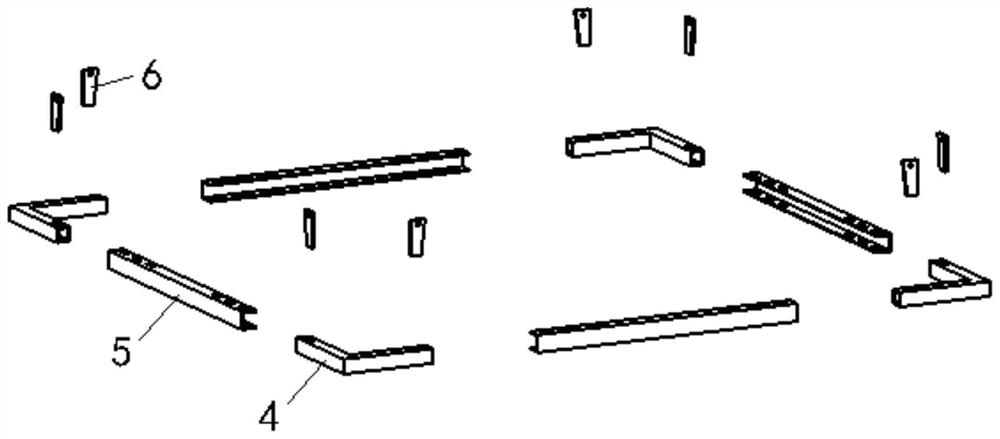

Formwork supporting method and device for large-section concrete column

PendingCN113073842AConstruction time savingLabor-saving constructionForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringStructural engineering

The invention discloses a formwork supporting method and device for a large-section concrete column. A set of connecting rods and a set of corner hoops are connected into rectangular hoops through a set of pin pieces, and a set of formworks are hooped into a rectangular cylinder through the rectangular hoops to serve as a pouring cavity of the large-section concrete column. The device has the scalability, and the size change of the large-section column can be met; and mounting and dismounting are easy and fast, and the beneficial effects of saving labor and time are achieved. Compared with an existing opposite-pull screw reinforcing method, an opposite-pull screw does not need to be arranged, and holes reserved in the opposite-pull screw do not need to be repaired after pouring. The device can be used in a turnover manner, and cost is saved.

Owner:CHINA CONSTR FOURTH ENG DIV

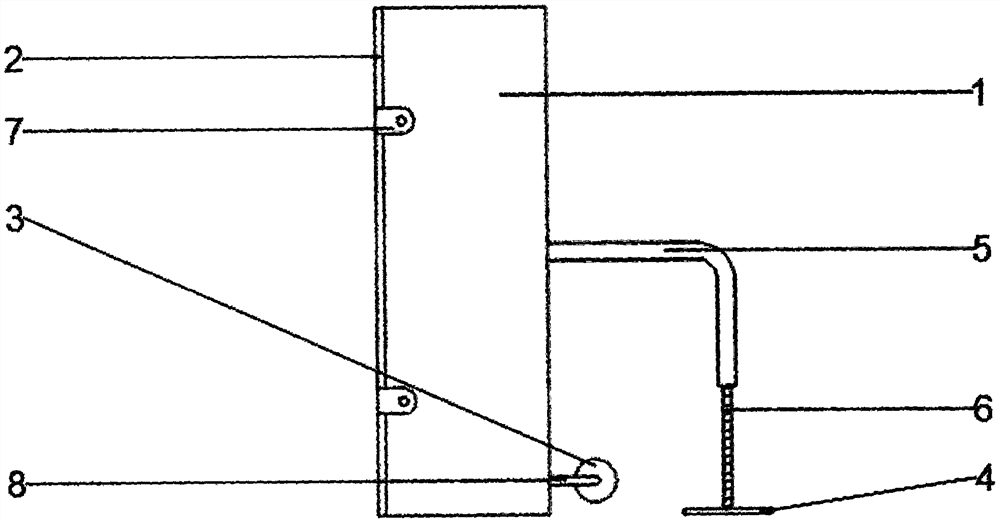

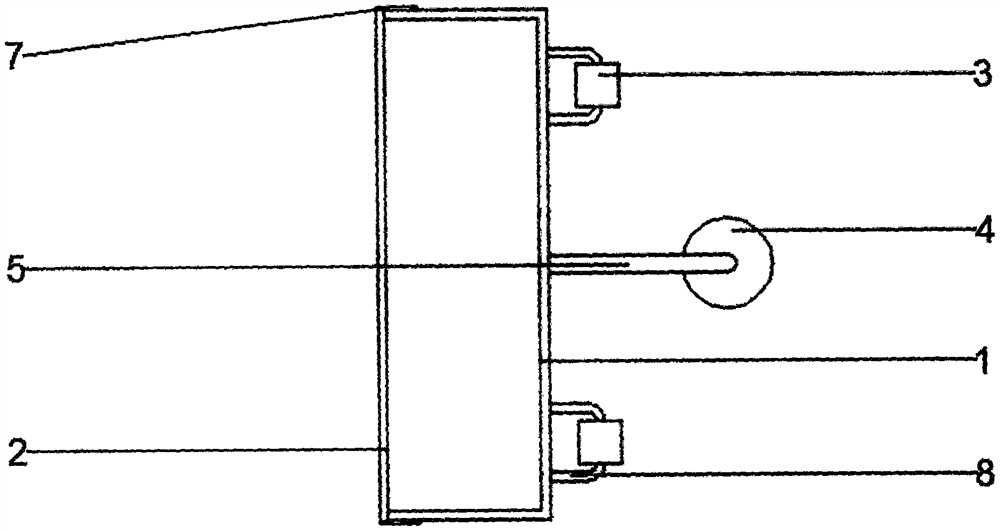

Special reamer for rock

A special reamer for rock comprises a reaming head, a first-stage reamer body, a connector, a second-stage reamer body, a top plate, a connection lead screw, a nut and a drill stem; the first-stage reamer body is arranged at the top end of the reaming head, and a reaming head convex block is embedded into a first-stage reamer body bottom groove to achieve limiting of the first-stage reamer body and the reaming head; the connector and the second-stage reamer body are arranged at the top end of the first-stage reamer body; a connection bottom block is embedded into a first-stage reamer body topconnection groove, and a connection top block stretches into a second-stage reamer body cavity; a connector convex block is embedded into a second-stage reamer body bottom groove, and a second-stage reamer body connection block is embedded into a first-stage reamer body connection groove, so that limiting of the second-stage reamer body and the first-stage reamer body is achieved; the top plate isembedded into a second-stage reamer body connection groove; the bottom end of the connection lead screw stretches into the device; the top end of the connection lead screw is fixed to the top plate due to threaded connection of the nut; and the drill stem is fixed to the connector and the reaming head in a threaded manner. The special reamer for the rock can be subjected to structural adjustmentaccording to the reaming size, and is flexible to use and high in structural strength.

Owner:ZHENJIANG KAIYUE TOOLS

Drill bit for construction of bored pile and construction method using the same

The invention discloses a drill bit for constructing bored piles and a construction method using the drill bit. The drill bit is provided with a mud scraping assembly and a detachable rib protecting block. The mud scraping assembly comprises a mud scraping plate (8) and installing plates (9), and the installing plates (9) are welded to the circumferential face of the inner circle of a block ring (3). A steel brush (17) is arranged on the outer side of the mud scraping plate (8). The mud scraping plate (8) is hung on the block ring (3) through a first clamping groove (10). An installing part (8.1) of the mud scraping plate (8) is located between the two installing plates (9) of the same set, and the installing part (8.1) of the mud scraping plate (8) and the installing plates (9) on the two sides are fixed in a threaded connection mode. The method is characterized in that in the drilling process, the mud scraping plate (8) is firstly installed on the block ring (3) so that a large hole with the size matched with that of a pile casing can be drilled, then the mud scraping plate (8) is taken down, and the rib protective block is installed so that a small hole with the size matched with the designed size of the bored piles can be drilled. By means of the drill bit and the construction method, sand soil between the pile casing and the pile holes can be effectively removed in a drilling mode.

Owner:浙江易通特种基础工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com