Special reamer for rock

A reamer and rock technology, applied in drilling equipment, earthwork drilling, drill bits, etc., can solve the problems of unchangeable hole size, unadjustable hole reaming requirements, complicated structure of reamer, etc., so as to improve the flexibility, The effect of firm fixing and smooth opening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

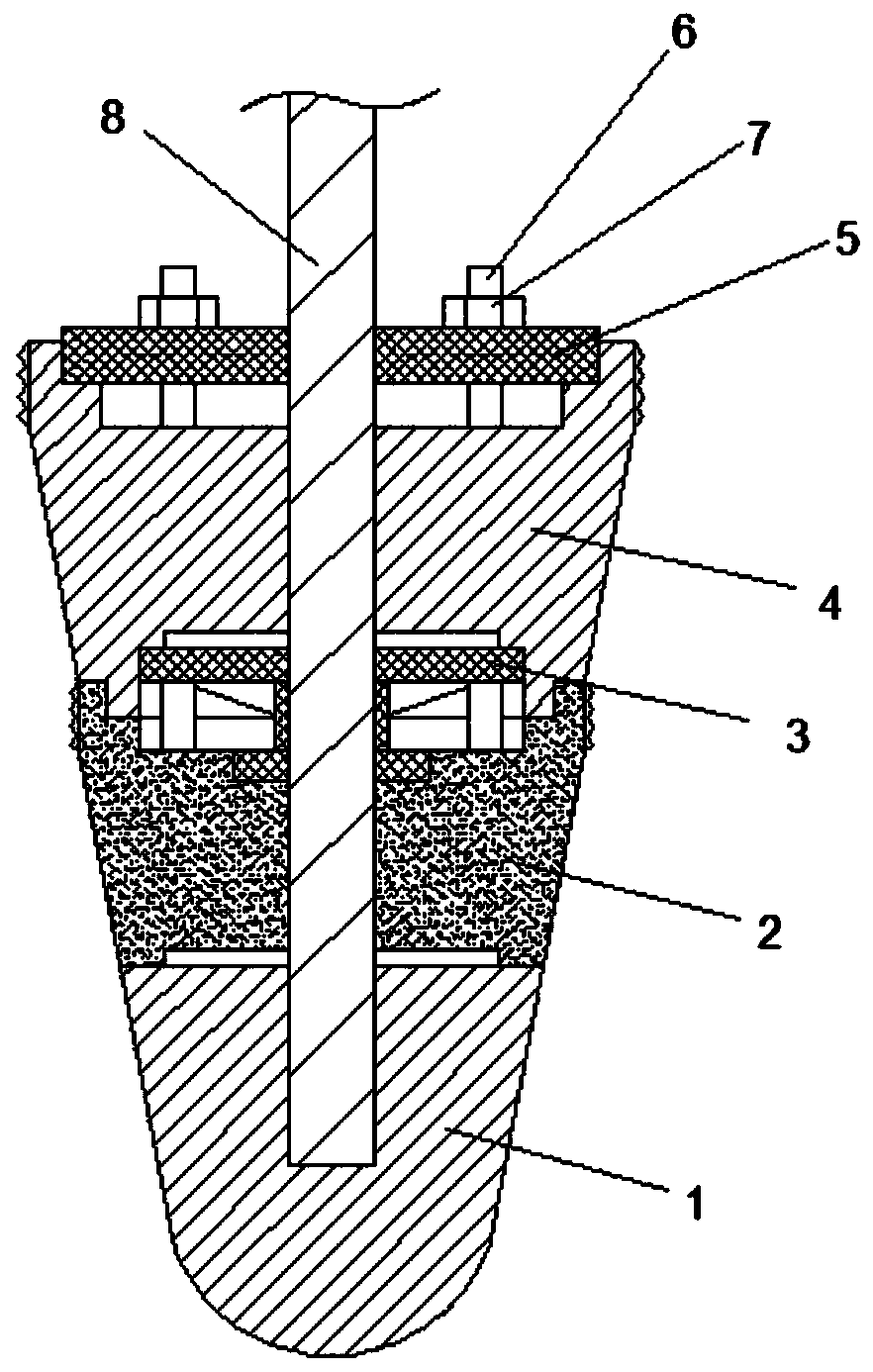

[0036] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are all well-known technologies known to those skilled in the art, such as welding and hot-melt integral molding.

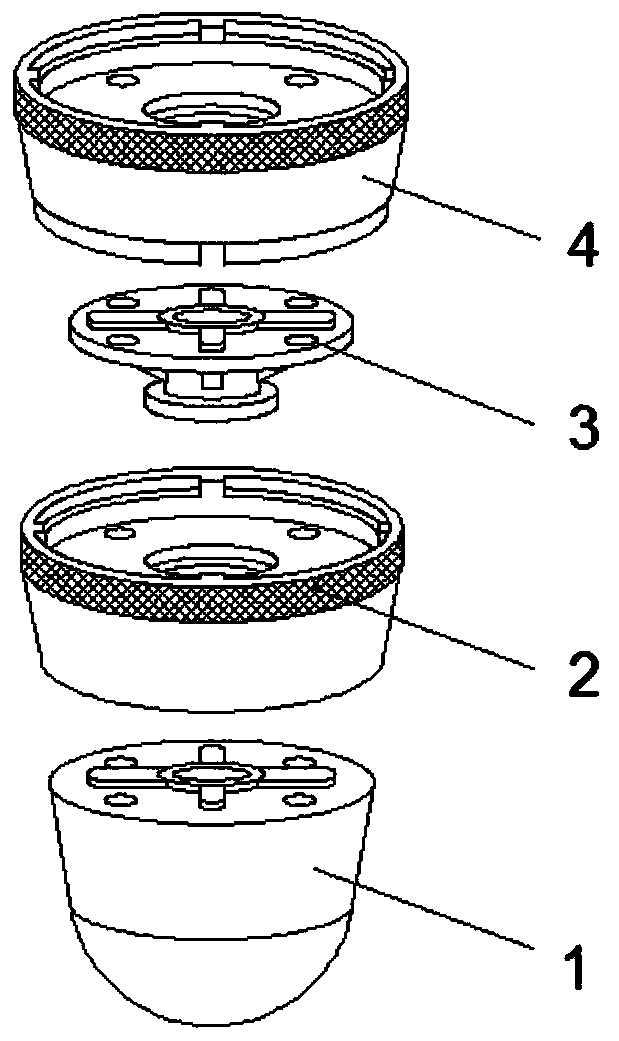

[0037] It can be seen from the accompanying drawings that a special reamer for rocks includes a reamer head, a primary reamer, a connector, a secondary reamer, a top plate, a connecting screw, a nut, and a drill rod;

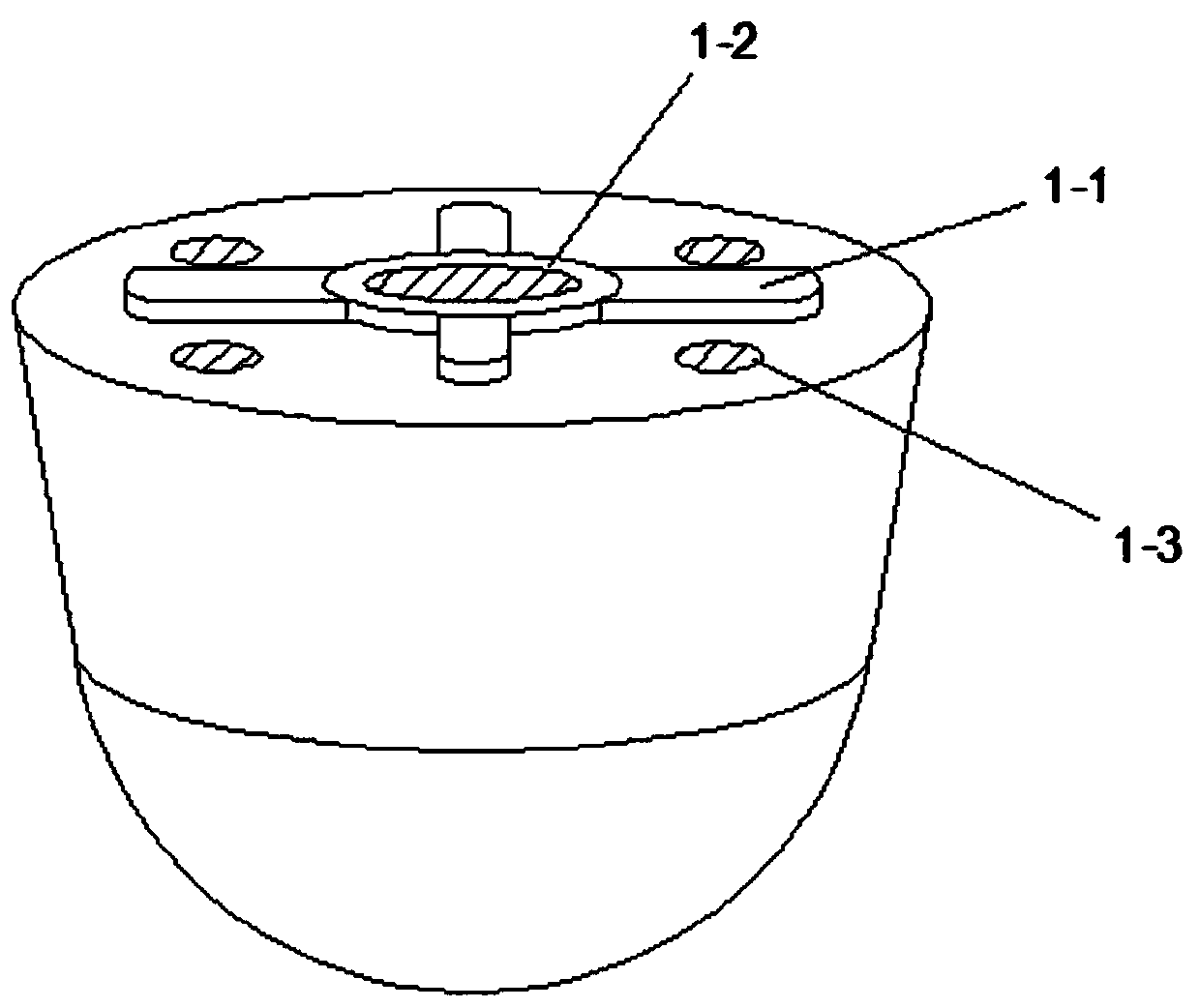

[0038] The reaming head is in the shape of a circular platform, and the reaming head is in a wide upper part and narrower lower part; the center of the top surface of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com