A spraying quick-setting liquid rubber waterproof coating and its production method

A liquid rubber and waterproof coating technology, applied in asphalt coatings, chloroprene homopolymer coatings, coatings, etc., can solve the problems of poor high and low temperature resistance, low elongation, low solid content, etc. The effect of high strength, strong anti-adhesion ability and low dryness requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A spray quick-setting liquid rubber waterproof coating, including three components A, B, and C, the A component is a waterproof material main agent solution, the B component is a catalyst and demulsifier solution, and the C group Divided into reinforced fiber solution;

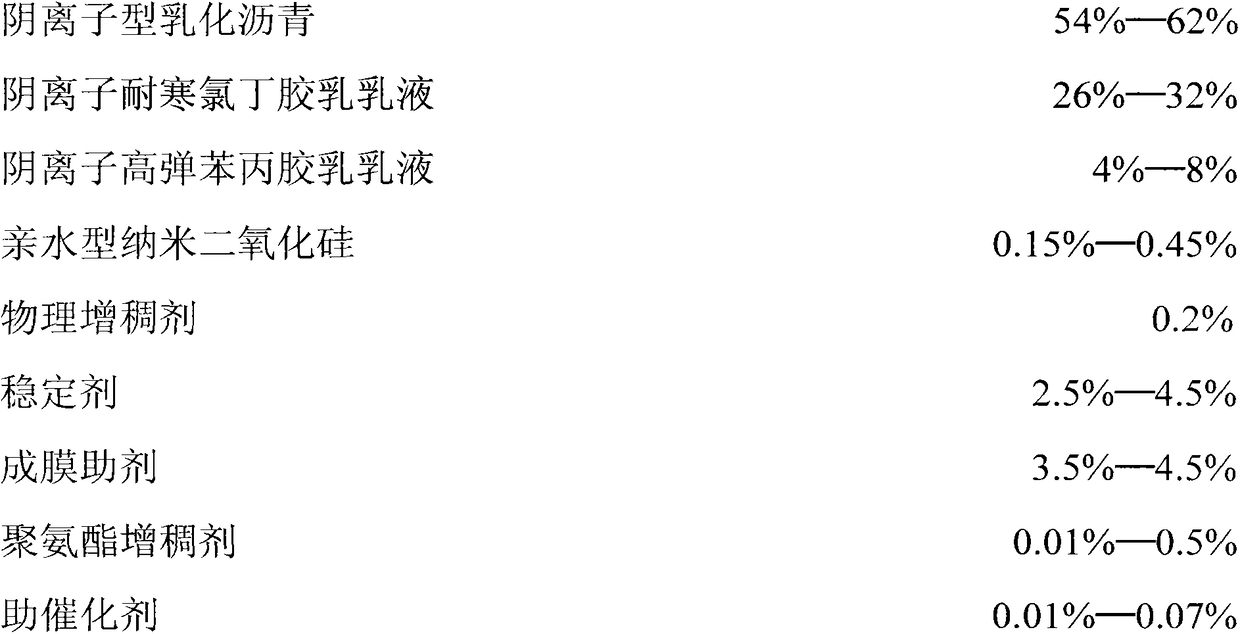

[0077] Described A component is expressed as:

[0078]

[0079]

[0080] The B component, expressed in mass percent, includes:

[0081] Main catalyst 0.5%

[0082] Demulsifier 11.5%

[0083] Deionized water 88%

[0084] The C component is a reinforcing fiber

[0085] The spraying capacity ratio of the A component, B component and C component is 10 / 1 / 0.1-10 / 1 / 0.3.

[0086] The A component: the physical thickener includes carboxymethyl cellulose; the stabilizer includes polyvinyl alcohol; the film-forming aid includes alcohol fat twelve; the polyurethane thickener includes non-ionic polyurethane; urea.

[0087] The main catalyst of the B component is selected from one or more of magnesium oxi...

Embodiment 2

[0103] A spray quick-setting liquid rubber waterproof coating, including three components A, B, and C, the A component is a waterproof material main agent solution, the B component is a catalyst and demulsifier solution, and the C group Divided into reinforced fiber solution;

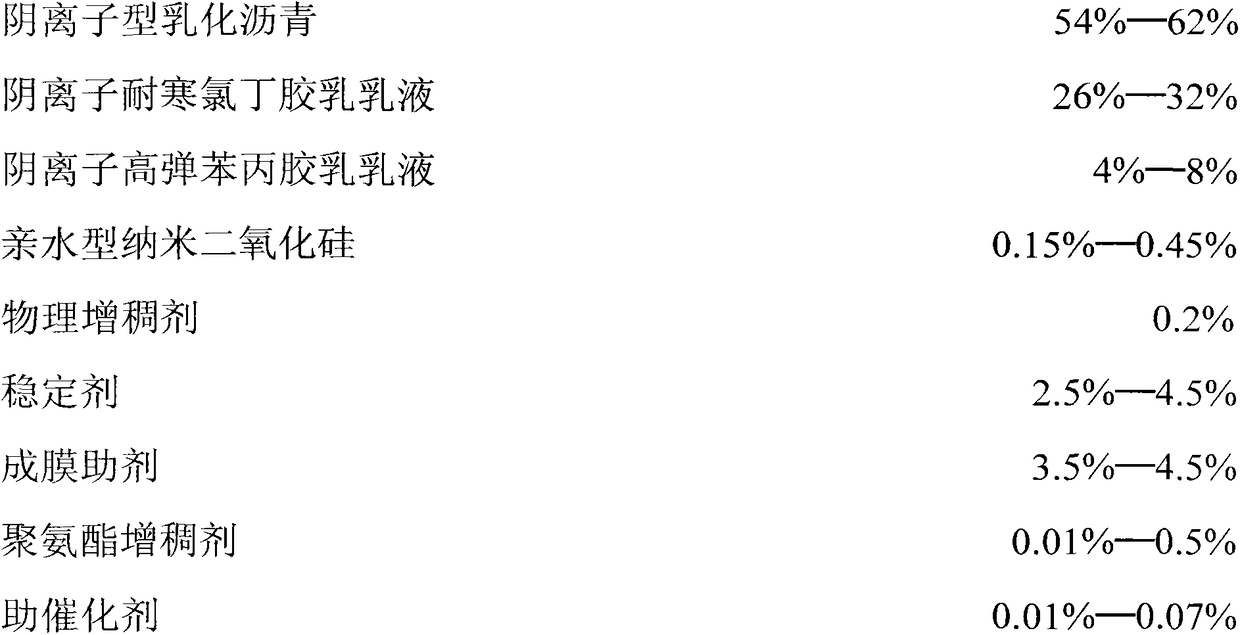

[0104] Described A component is expressed as:

[0105]

[0106]

[0107] The B component, expressed in mass percent, includes:

[0108] Main catalyst 0.5%

[0109] Demulsifier 11.5%

[0110] Deionized water 88%

[0111] The C component is a reinforcing fiber

[0112] The spraying capacity ratio of the A component, B component and C component is 10 / 1 / 0.1-10 / 1 / 0.3.

[0113] The A component: the physical thickener includes carboxymethyl cellulose; the stabilizer includes polyvinyl alcohol; the film-forming aid includes alcohol fat twelve; the polyurethane thickener includes non-ionic polyurethane; urea.

[0114] The main catalyst of the B component is selected from one or more of magnesium oxi...

Embodiment 3

[0130] A spray quick-setting liquid rubber waterproof coating, including three components A, B, and C, the A component is a waterproof material main agent solution, the B component is a catalyst and demulsifier solution, and the C group Divided into reinforced fiber solution;

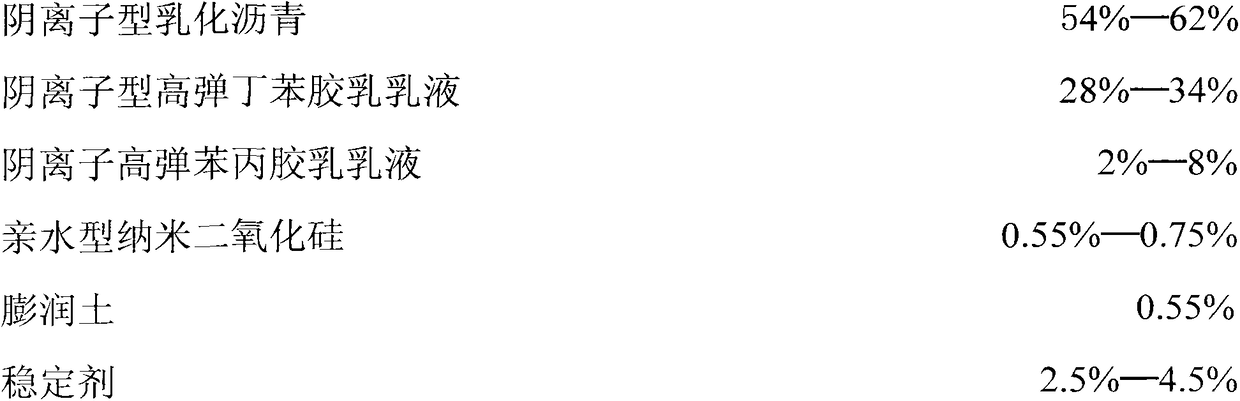

[0131] Described A component is expressed as:

[0132]

[0133]

[0134] The B component, expressed in mass percent, includes:

[0135] Main catalyst 0.5%

[0136] Demulsifier 11.5%

[0137] Deionized water 88%

[0138] The C component is a reinforcing fiber

[0139] The spraying capacity ratio of the A component, B component and C component is 10 / 1 / 0.1-10 / 1 / 0.3.

[0140] The A component: the physical thickener includes carboxymethyl cellulose; the stabilizer includes polyvinyl alcohol; the film-forming aid includes alcohol fat twelve; the polyurethane thickener includes non-ionic polyurethane; urea.

[0141] The main catalyst of the B component is selected from one or more of magnesium oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com