Frame spinning plug-in type integrated inner partition wall plate and installation method thereof

An internal partition wall, plug-in technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of increasing construction difficulty and cost, increasing construction waste, and plastering the surface layer empty drum, etc., to improve the utilization rate of materials, recyclable Use low, increase the effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

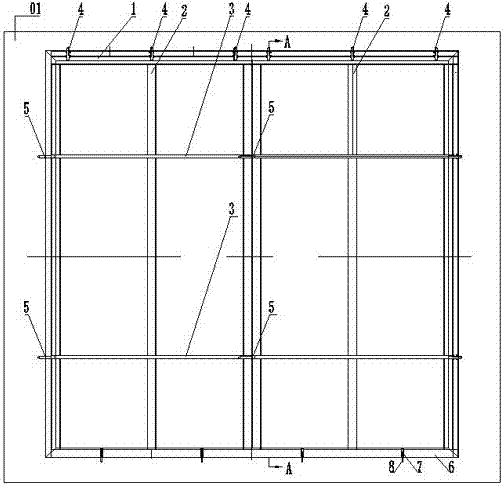

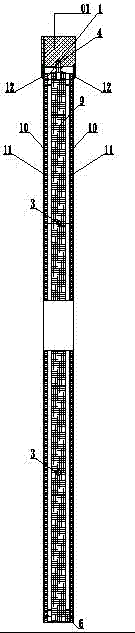

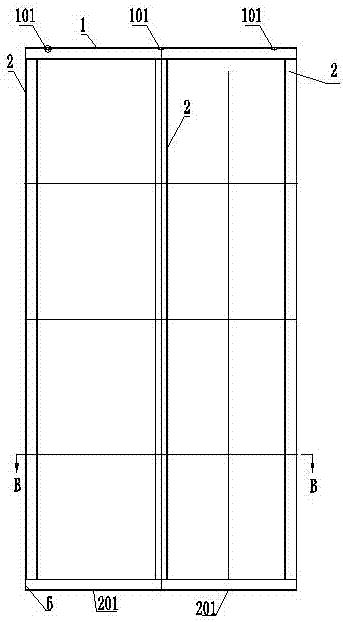

[0037] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0038] like Figure 1-11 It shows an embodiment of a frame spinning and plug-type integrated inner partition wall panel: it includes a steel frame, an inner insulation layer (extruded board or glass wool, expanded perlite, etc.), a base board (cement board, plaster board, silicon Calcium acid board, etc.), surface decorative boards and decorative frame strips, the steel frame includes upper rails 1, lower rails 6, vertical braces 2, horizontal support tubes 3, spinning screw pins 4, fixed pins 5, guide Set of 7, movable pin 8,

[0039] The surface of the upper crosspiece 1 is formed with a turning hole 101, and its inner diameter is in clearance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com