Polypropylene apparatus grade switching and controlling method

A control method and brand switching technology, applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of difficulty in online operation, poor practicability, and complex design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

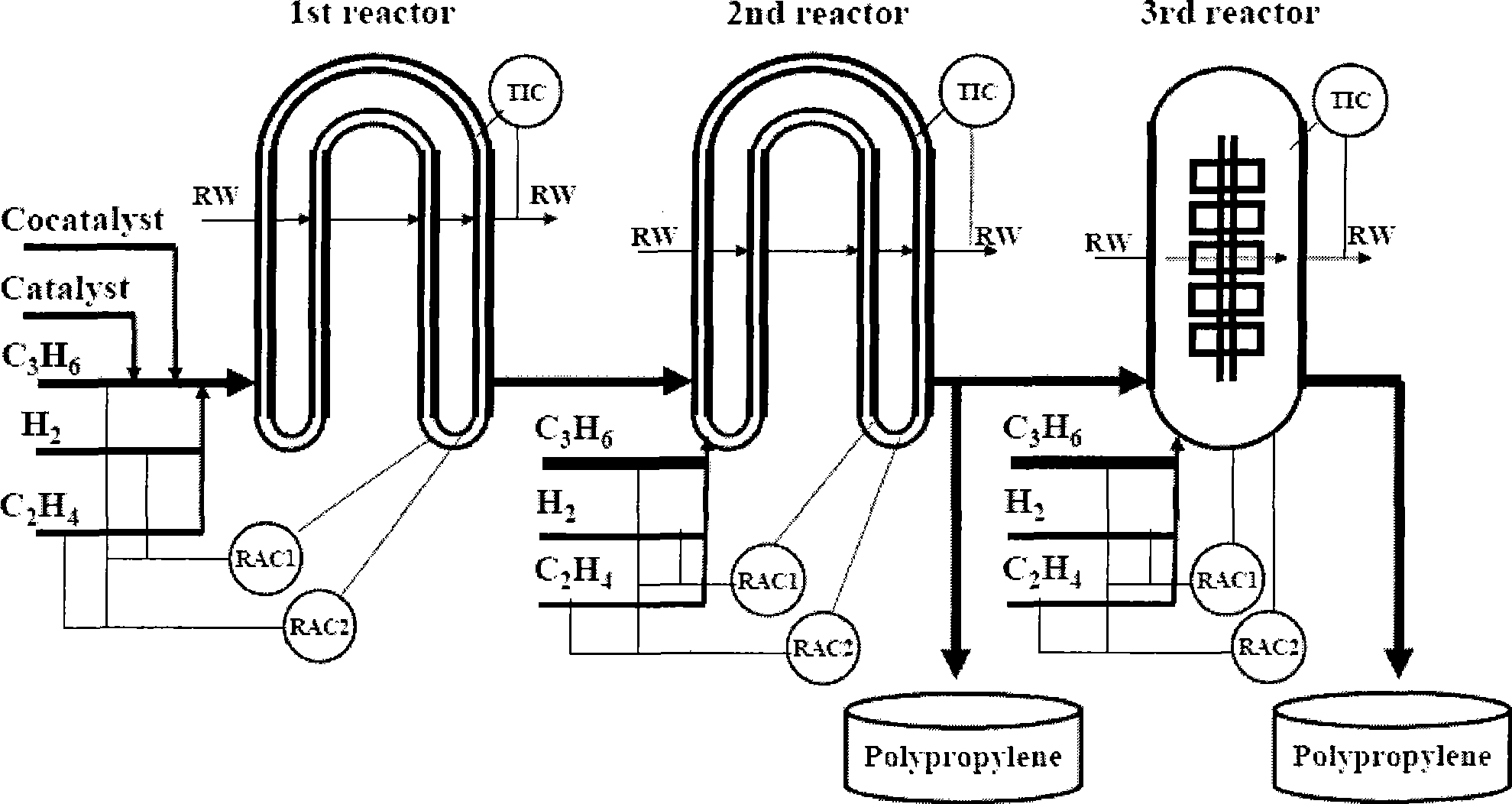

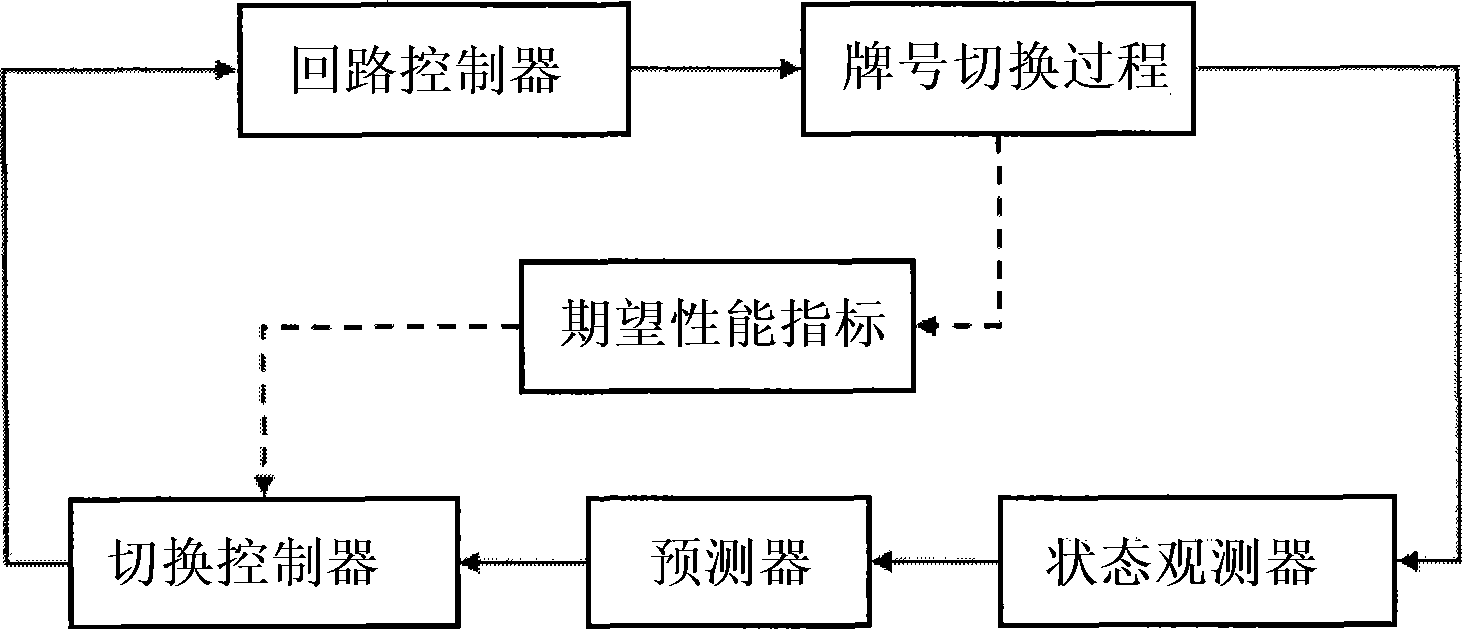

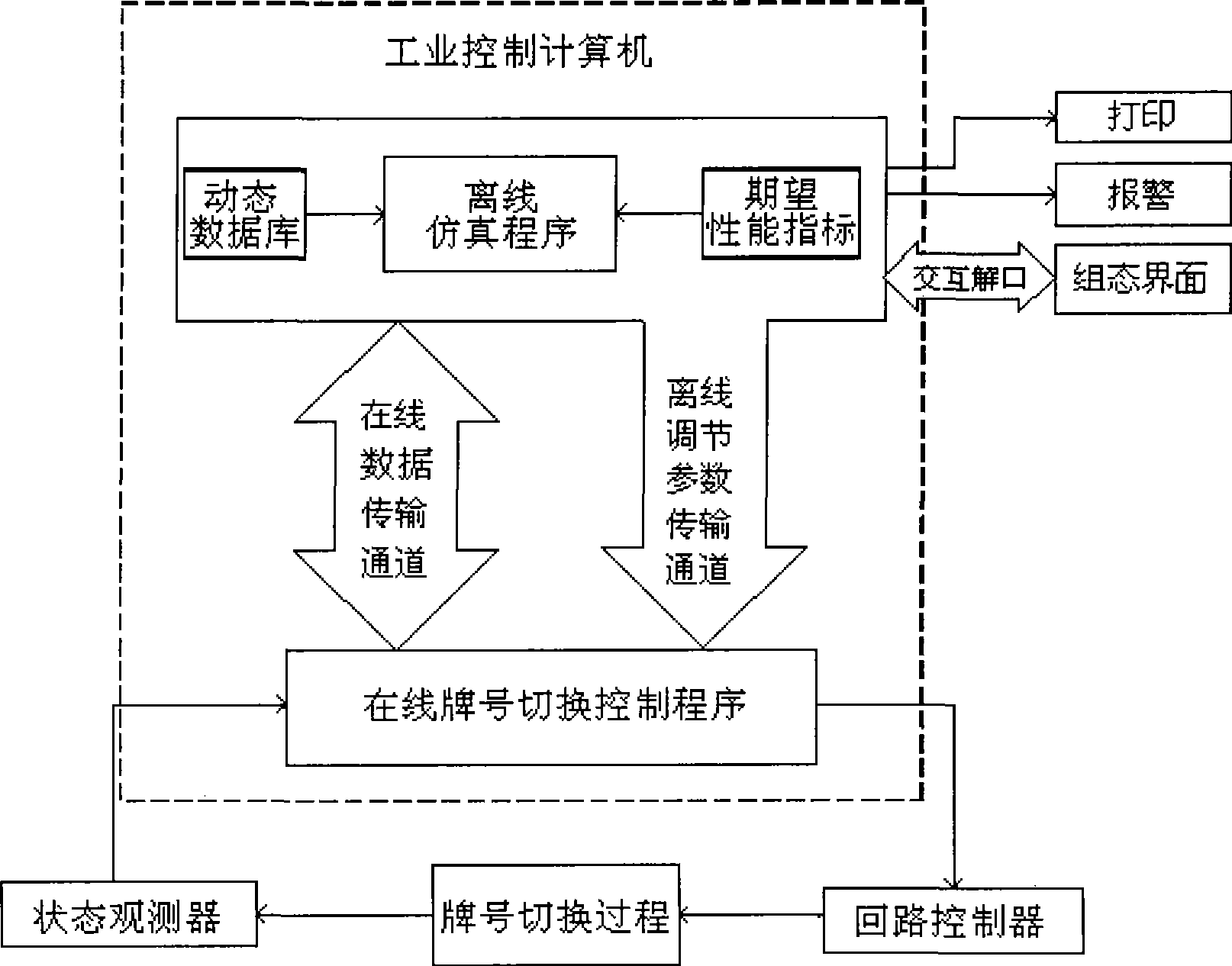

[0068] The present invention will be further described below in conjunction with the accompanying drawings.

[0069] refer to Figure 1 to Figure 4 , a polypropylene device brand switching control method, the control method comprises the following steps:

[0070] 1), establish a discrete-time state-space model of polypropylene grade switching process, see formula (1a) and formula (1b):

[0071] x ( t + 1 ) = A 1 x ( t ) + B 1 v ( t ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com