Adjustment tool for large-motor rotor and stator

A technology for adjusting tools and large motors, applied in the direction of centering/balancing rotors, mechanical clearance measurement, etc., can solve the problems of inability to improve equipment installation accuracy, low work efficiency, long time, etc., to achieve convenient measurement, fast measurement speed, Reduce the effect of monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

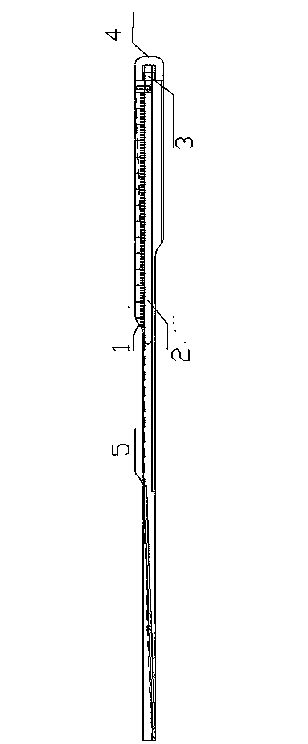

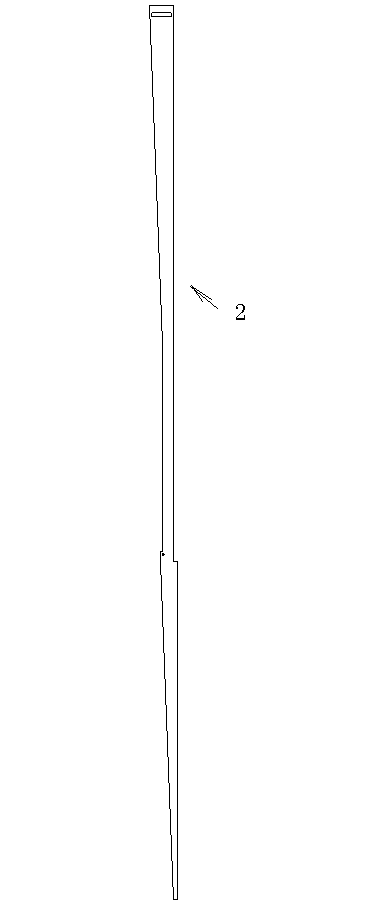

[0012] like figure 1 As shown, a large-scale motor stator and rotor adjustment tool includes a main scale 1 and an auxiliary scale 2. The inside of the main scale 1 is hollow, with a scale on the outside, an open groove on the side, and two walls on one side of the main scale. All are provided with a slope 3 from inside to outside and from top to bottom; the auxiliary ruler 2 is inserted into the inside of the main ruler 1, and the head end side has a slope 4 corresponding to the internal slope 3 of the main ruler, and the starting point of the auxiliary ruler slope is set There is a sliding shaft 5, and the tail end of the auxiliary scale is provided with a slide block 6 inserted into an opening groove on the surface of the main scale.

[0013] In the stator-rotor adjustment tool for large motors, an end cover 7 is provided at the tail end of the main ruler.

[0014] The probe consists of 5 parts, namely the main ruler 1, the auxiliary ruler 2, the push slider 3, the end cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com