Construction method of protection layer of foundation pit oblique plane waterproof layer

A technology of protective layer and waterproof layer, which is applied in the direction of protective devices, infrastructure engineering, construction, etc., can solve the problems of time-consuming construction process, difficult construction, poor effect, etc., and achieve less investment, convenient construction, and rapid laying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

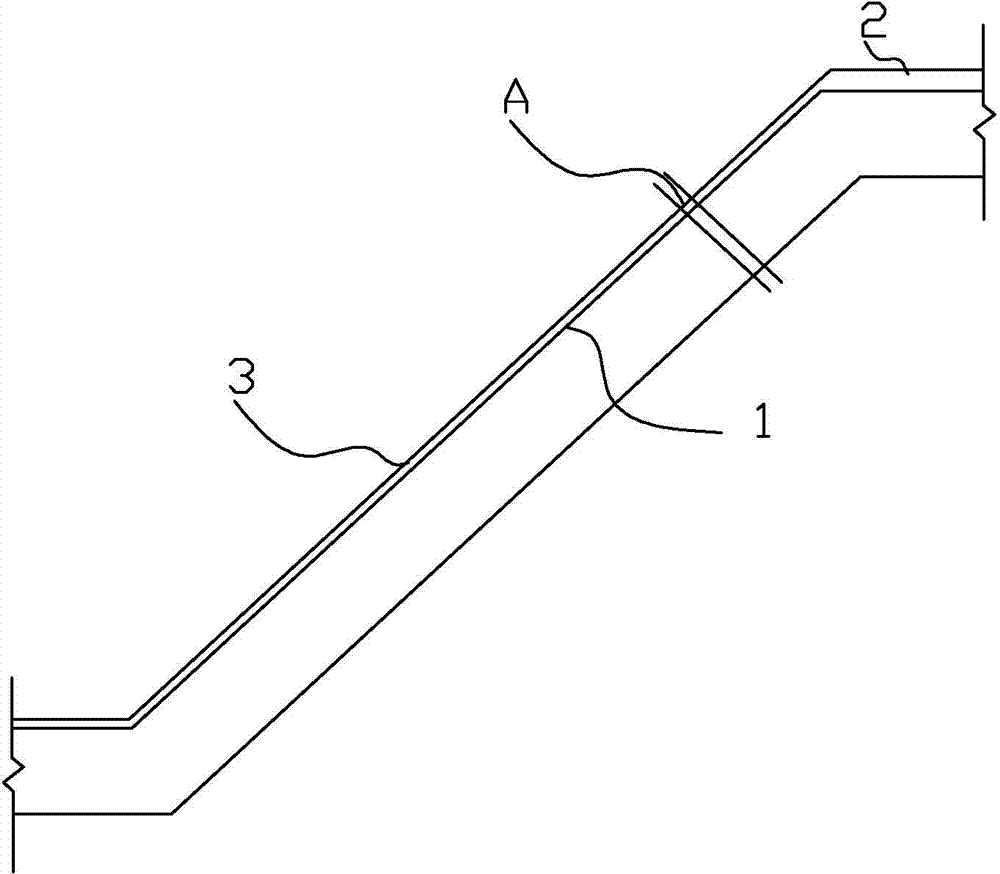

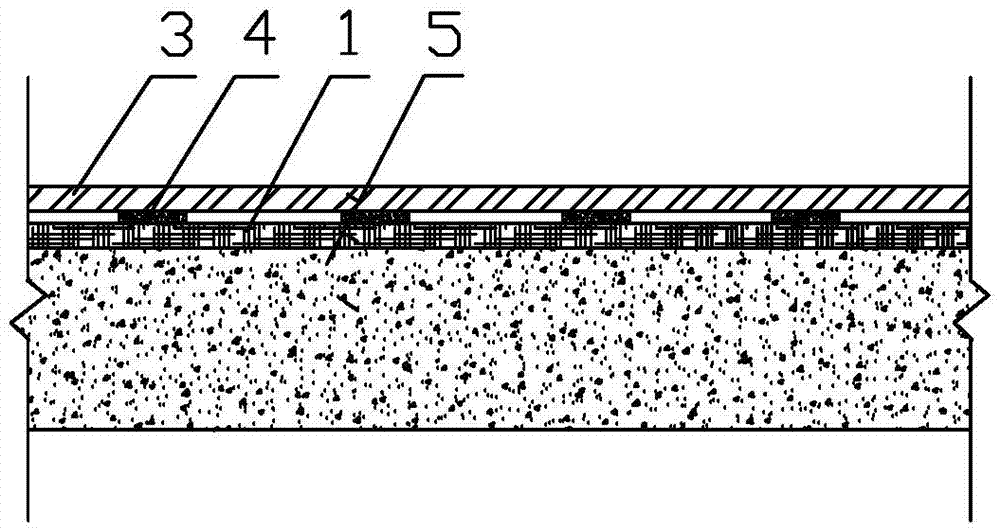

[0021] A construction method for the protective layer of the foundation pit slope waterproof layer. The method is to use galvanized iron sheet instead of conventional fine stone concrete as the construction method of the waterproof layer protection layer on the slope of the foundation pit waterproof layer with a degree of ≥ 45 degrees. The construction method The specific steps are:

[0022] A. Protective layer preparation: Customize the metal skin with good extensibility according to the slope area of the waterproof layer of the foundation pit to be constructed as the protective layer;

[0023] B. Paste the protective layer on the slope of the waterproof layer: apply adhesive on one side of the protective layer and lay it outside the waterproof layer of the slope;

[0024] C: Trimming and filling: Trim according to the actual situation on site and use a small amount of galvanized iron sheet to fill in the detailed laps.

[0025] In this construction method, the metal skin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com