Rib-line-shaped prestressed concrete pipe pile

A technology of concrete pipe piles and prestressing, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, and can solve problems such as the decline in the bearing capacity of concrete pipe piles, the shortened service life of buildings, and the settlement of buildings. Firmness, enhanced supporting force and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

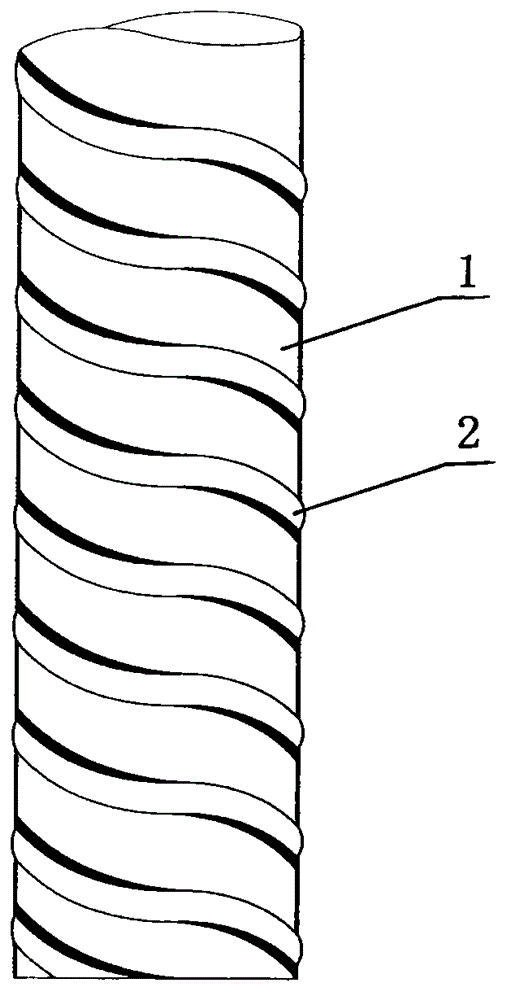

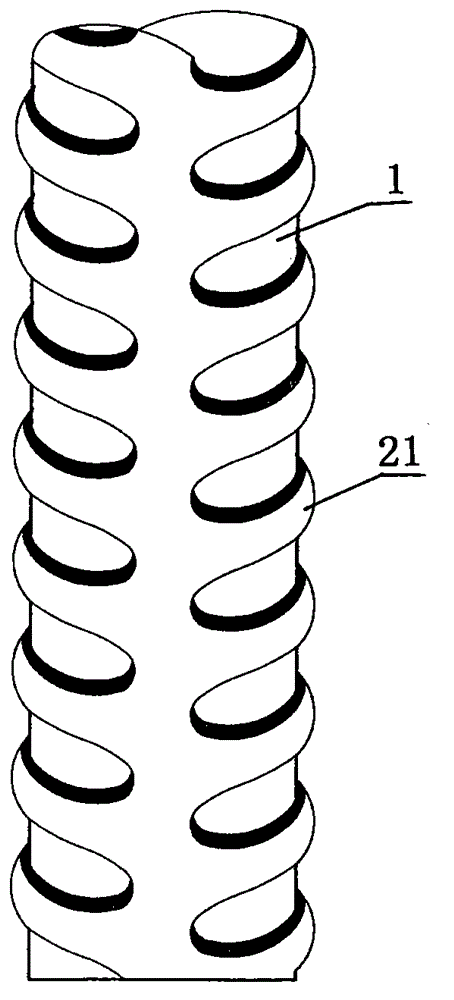

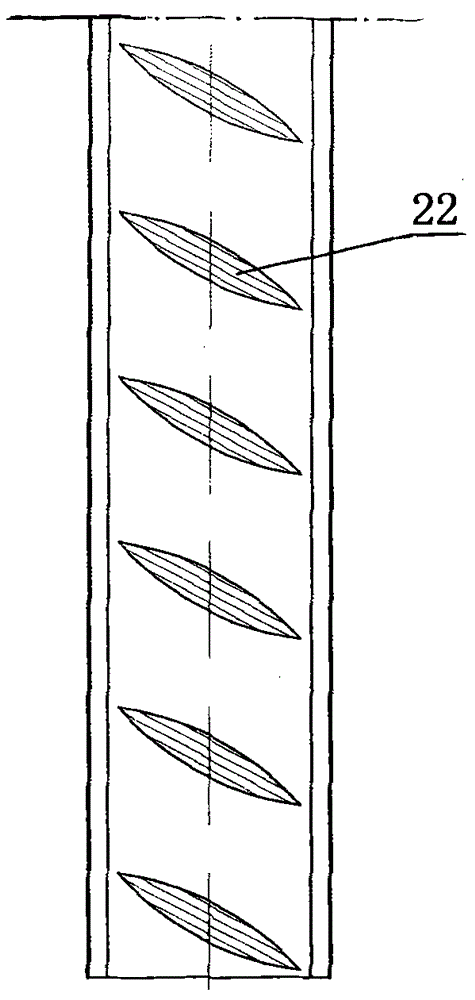

[0015] Such as Figure 1 to Figure 6 As shown, a ribbed prestressed concrete pipe pile is composed of a pile body 1 . Protruding ribs 2 or protruding movable outer wings are provided on the peripheral wall of the pile body. The protruding ribs and protruding movable outer wings can increase the surface area of the peripheral wall of the pile body, increase the friction force with the soil layer, and greatly improve the friction coefficient between the concrete pipe pile and the foundation soil layer.

[0016] Such as figure 1 As shown, the ribs are rectangular strips distributed helically at intervals. The distance from the spirally distributed rectangular strips protruding from the outer peripheral wall of the pile body is 2 to 15 cm, which can be set according to the texture of the foundation. The softer the texture of the foundation, the higher the rectangular strips protrude from the outer peripheral wall of the pile body. Ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com