Production process for prefabricated steel bar component

A technology of prefabricated components and production technology, applied in the field of construction, can solve the problems of material waste, lower production efficiency, pockmarks and holes, etc., and achieve the effect of simple construction steps, fast construction, labor saving, and reduced gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

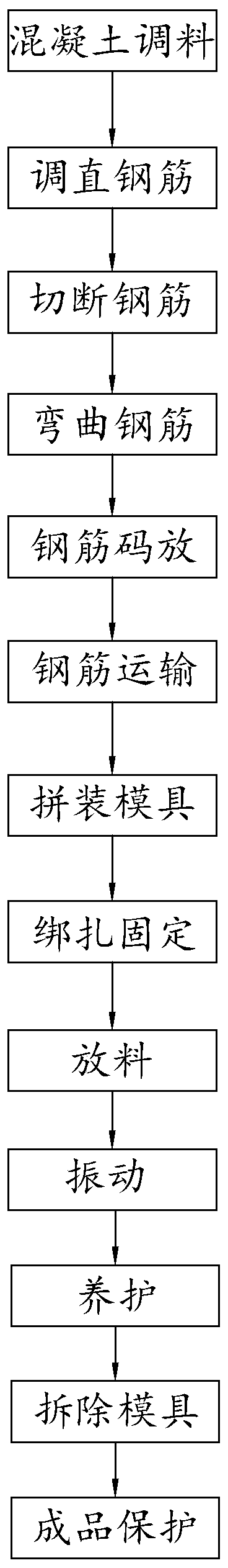

Image

Examples

Embodiment Construction

[0031] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

[0032] A production process for steel prefabricated components, the raw materials include cement, lime, sand, and steel bars;

[0033] The construction steps are as follows:

[0034] (1) After weighing the cement, the lime, and the sand, add them into a mixer and mix them evenly, add water into the mixer, and continue stirring for 15-20 minutes to obtain uniform concrete;

[0035] (2) Before straightening the steel bar cutting machine, check th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com