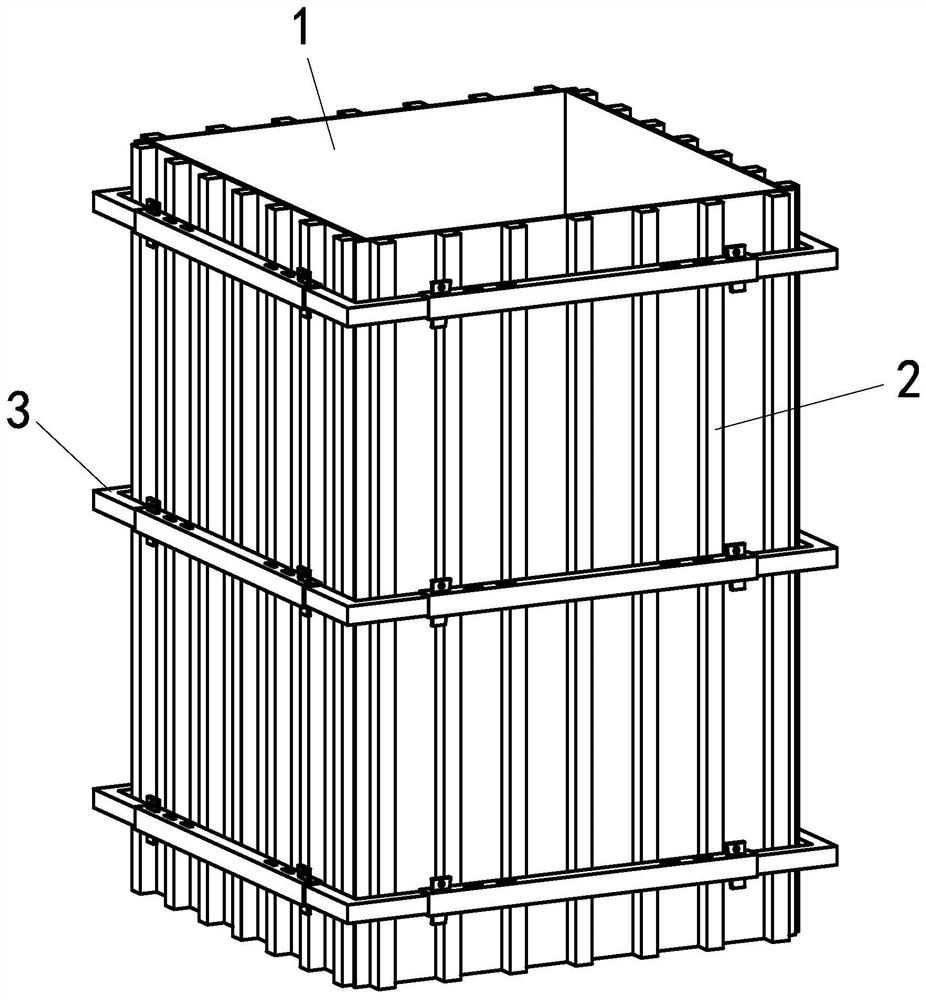

Formwork supporting method and device for large-section concrete column

A technology of concrete column and formwork method, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, connection of formwork/formwork/work frame, etc., can solve the problem of poor molding quality, waste of materials, issues such as increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

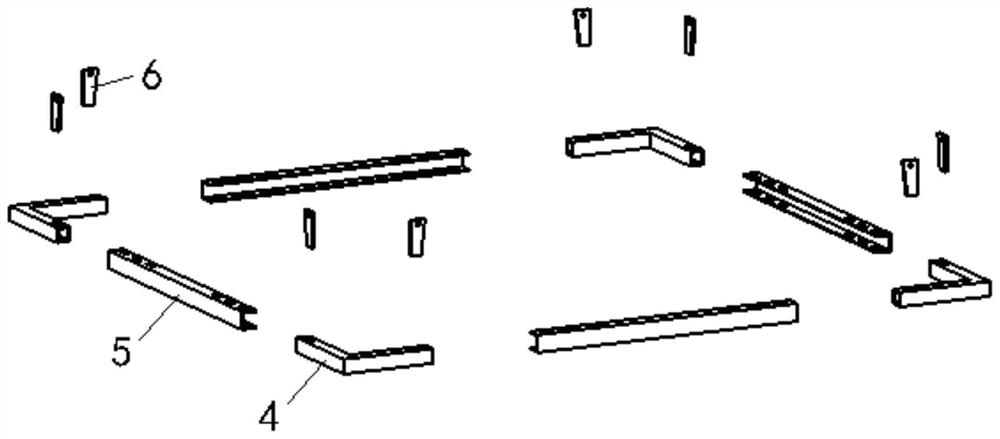

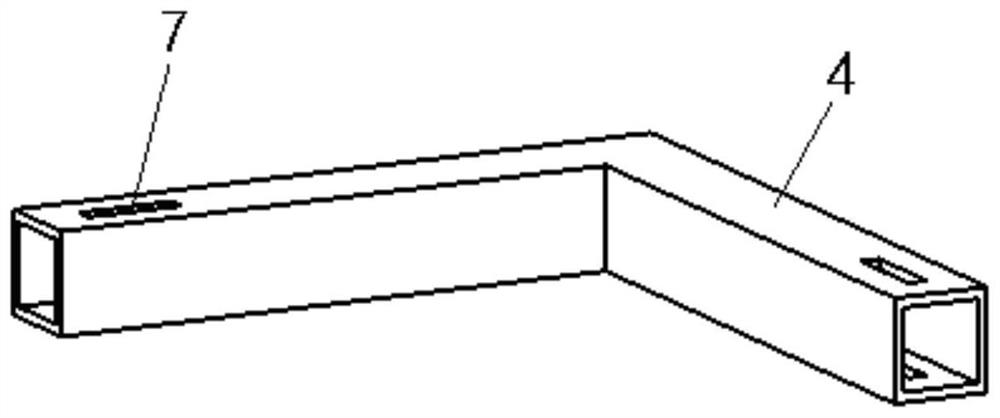

[0028] In the specific implementation, the square steel pipe is used to press image 3 Four corner hoops 4 are produced as shown, and a pin hole 7 is processed at both ends of each corner hoope 4. The shape of the pin hole 7 is a long rectangular structure, and the pin hole 7 is a through hole that penetrates up and down. Another example Figure 5 As shown in the figure, four sections of channel steel are taken as the connecting rod 5, and the opening width of the channel steel should be slightly larger than the outer dimension of the square steel pipe used for the angle hoop 4. The length of the connecting rod 5 can be determined according to the size of the large-section concrete column to be poured, and a certain adjustment length is reserved. Then, a group of pin holes 7 are respectively machined at both ends of the connecting rod 5, the pin holes 7 are machined on the two wings of the channel steel, and the distance between the pin holes 7 and the pin holes 7 is 50mm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com