Suspended structure with multiple combination modes

A hanging piece and hanging hole technology, applied in building components, building structures, buildings, etc., can solve the problems of high decoration cost, complex construction process, low construction efficiency, etc., and achieve convenient construction and low technical level requirements. , install fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

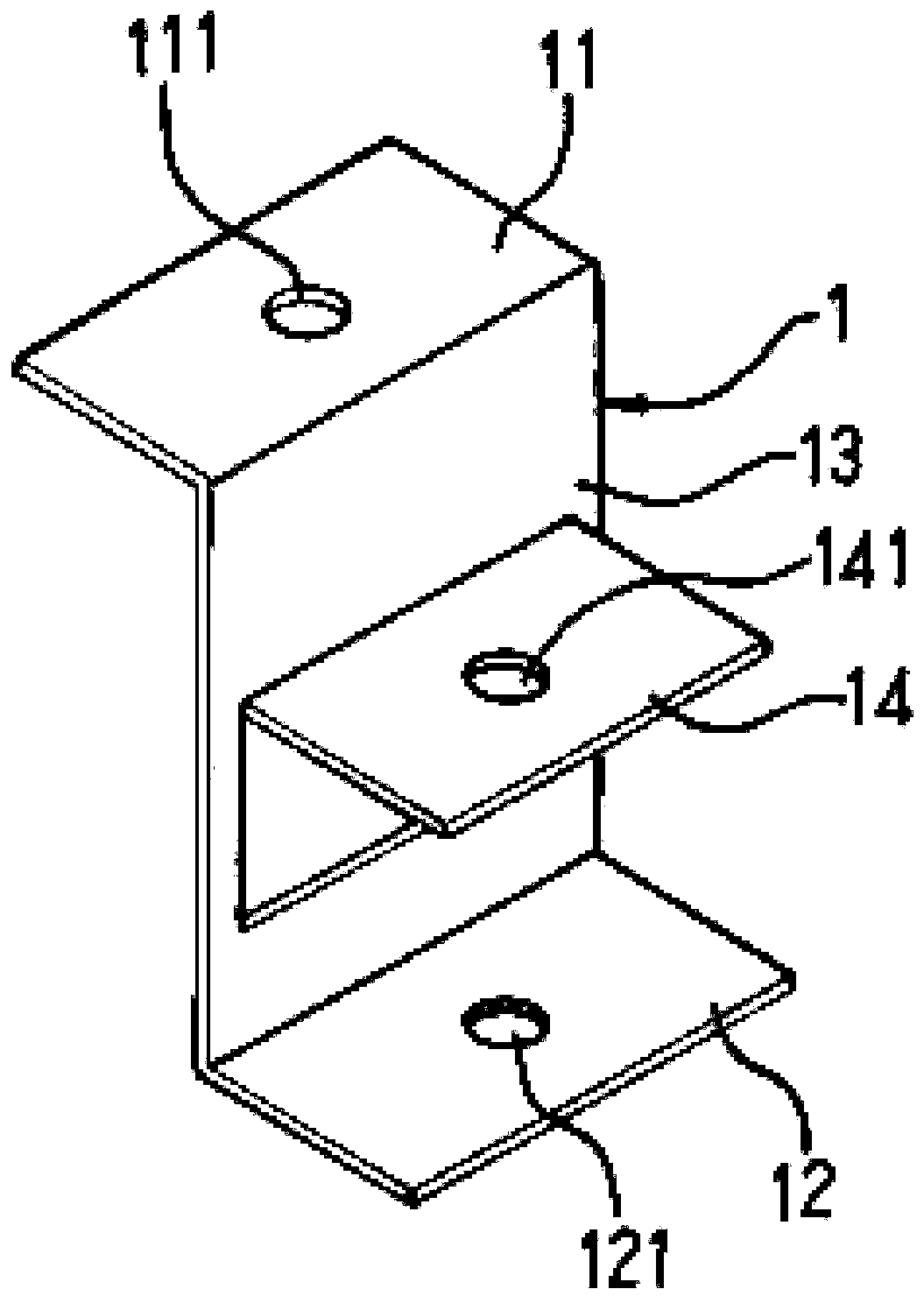

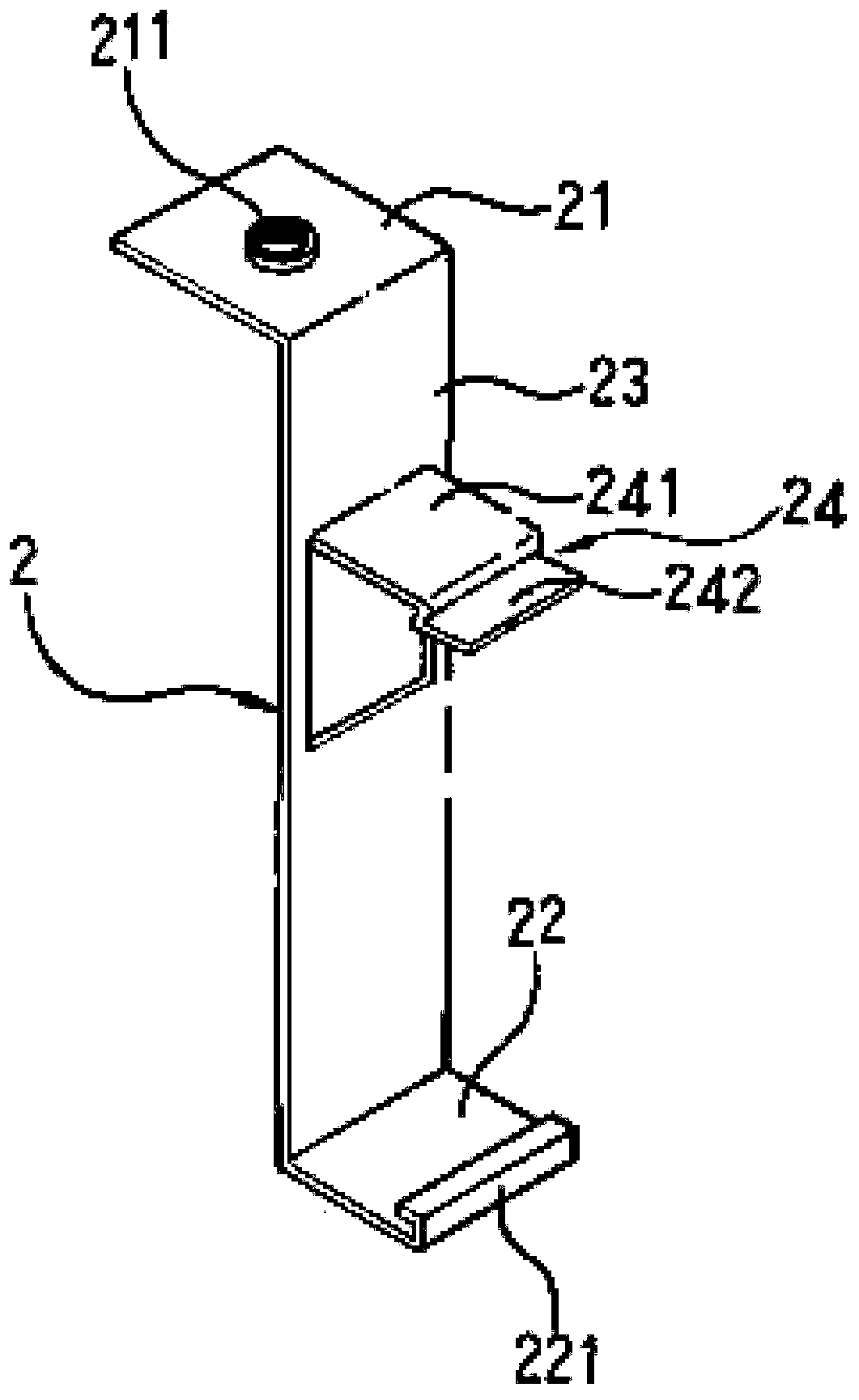

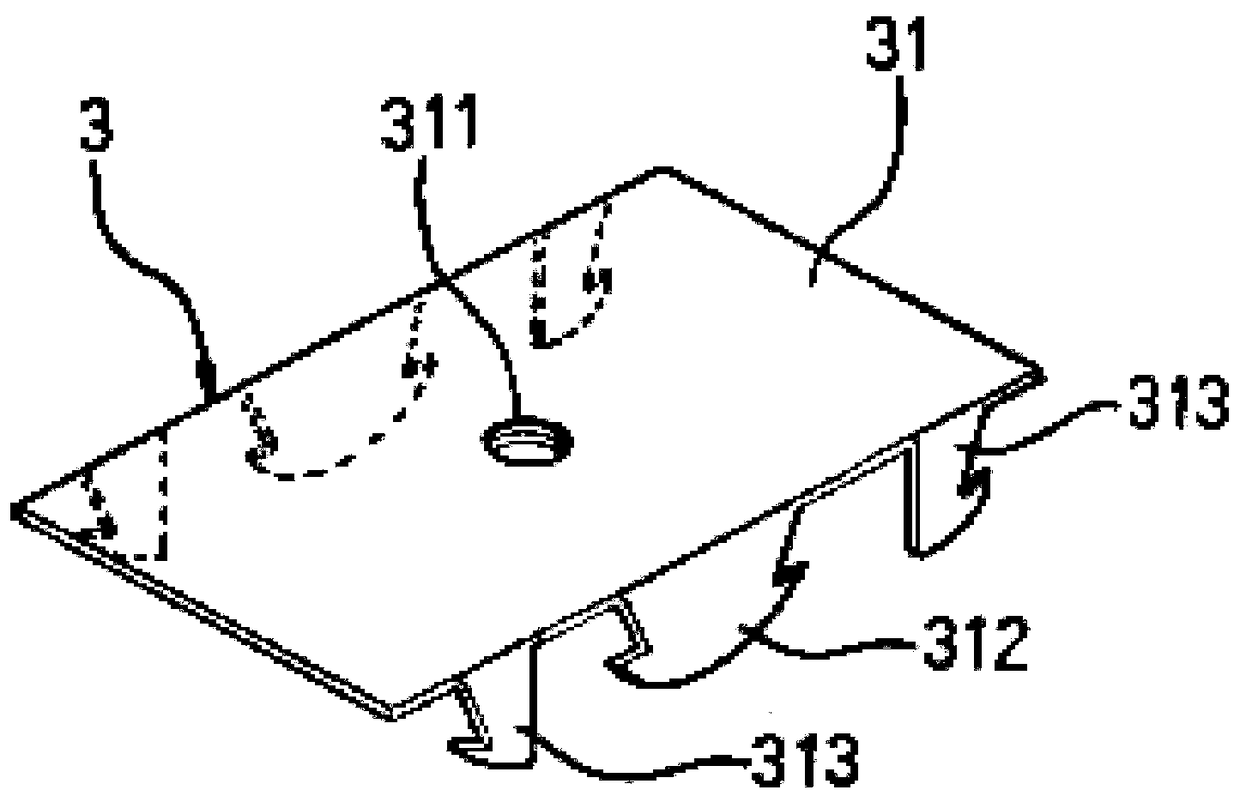

[0051] Such as Figure 7 As shown, first use a nail gun to fix the steel nail 6 to the roof surface through the fixing hole 111 of the upper plate 11 of the roof surface hanging part 1, and then insert the screw rod 7 into the first hanging hole 121 and the second hanging hole 121. Hole 141, the upper end of the screw rod 7 is fixed with a nut, the lower end of the screw rod 7 is connected with the sheet body screw hole 311 on the sheet body 31 of the cladding keel hanger 3, and then the first hook on the two sides of the cladding keel B B1 and the second hook B2 are hooked on the two pairs of hooks 313 on the cladding joist hanger 3, so that the cladding joist B is hooked in the up and down direction, and the cladding joist B can be on the two pairs of buckles 313 Slide horizontally to facilitate the installation and construction of the cladding keel B.

[0052] Such as Figure 8 As shown, similarly, a pair of buckle teeth 312 on the cladding keel hanger 3 can be hooked wit...

no. 3 example

[0054] Such as Figure 10 As shown, first use a nail gun to fix the steel nail 6 to the roof surface through the fixing hole 111 of the upper plate 11 of the roof surface hanging part 1, and then penetrate the screw rod 7 into the fourth hole on the T-shaped keel hanging part 5 in sequence. Hanging hole 531, the third hanging hole 511 and the first hanging hole 121 and the second hanging hole 141 on the roof surface hanging piece 1, the upper end of the screw rod 7 is fixed with a nut, and the lower end of the screw rod 7 is also fixed with a nut , and then hang the end of the T-shaped keel C riser in the hanging interface 521 of the T-shaped keel hanging part 5, so that the T-shaped keel C is suspended in the up and down direction, and the T-shaped keel C can be hung on the hanging interface. 521 slide horizontally. The lower part of the connecting plate 52 is provided with an opening 5211 for allowing the riser of the T-shaped keel C to pass through, so that the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com