Novel stainless steel skirting construction method used in color steel plate wall

A construction method and color steel plate technology, applied in the field of light steel structure workshop color steel plate wall and floor skirting, can solve the problems of inconvenience and inconvenience, and achieve the effect of visual effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A novel stainless steel skirting construction method for color steel plate walls, comprising the following steps:

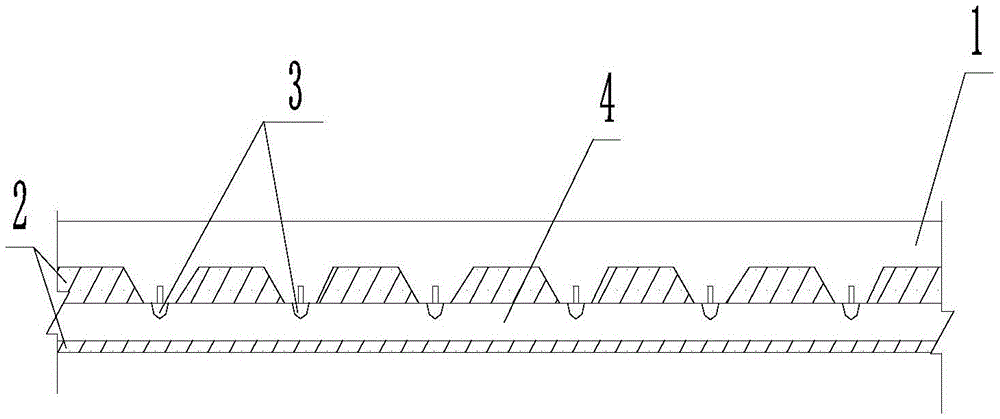

[0020] 1. Production of stainless steel skirting line 4: Send the detailed drawing of the shape and size of the stainless steel skirting line 4 to the local metal processing factory. After the stainless steel skirting line is made, it will be transported to the construction site. , Angle grinder and other tools are ready for the next step of construction.

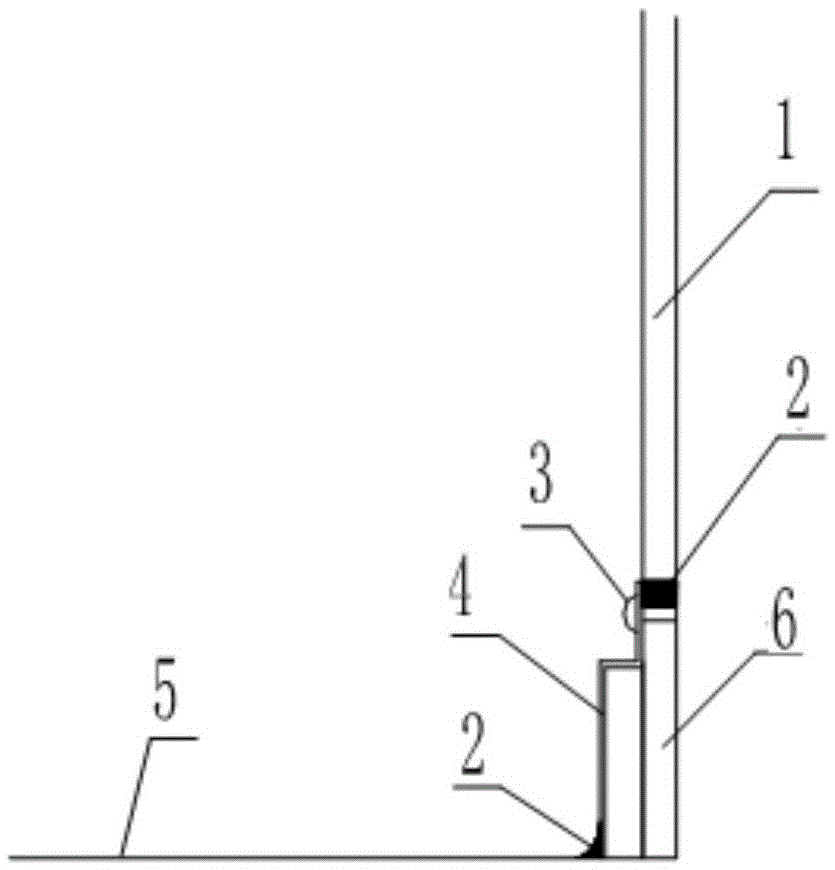

[0021] 2 Installation of stainless steel skirting line: place the bottom of the stainless steel skirting line close to the ground, and at the same time place the stainless steel skirting line 4 close to the color steel plate wall 1. After these two places are firmly placed, raise the upper part of the stainless steel skirting line and the color steel plate 3 links with rivets. After processing a whole baseboard in this way, connect the first baseboard of the next baseboard to the end of the previous ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com