Environmentally friendly efficient silt remover and construction method thereof

A desilting machine and environmental protection technology, applied in the direction of earth mover/excavator, construction, etc., can solve the problems of urban environmental pollution, increase in transportation costs, and inability to realize cleaning work, etc., to achieve convenient cleaning, convenient operation, and efficient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

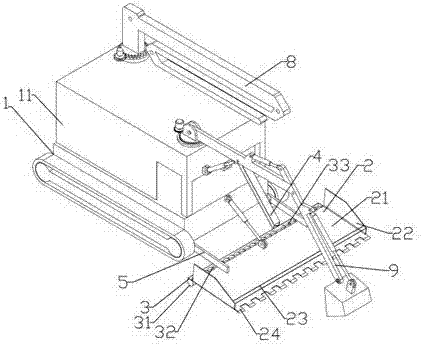

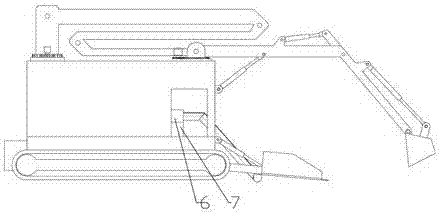

[0023] Combine below figure 1 and Figure 4 And further illustrate the technical solution of the present invention through specific examples.

[0024] An environment-friendly and high-efficiency dredging machine, comprising a silt transporting device, the silt transporting device includes a traveling vehicle body 1, a box body 11 is arranged on the traveling vehicle body 1, and a shoveling mechanism 2 is provided at the front end, and the silting shoveling device A first screw conveyor 3 is arranged between the mechanism 2 and the traveling vehicle body 1, and a second screw conveyor 4 that passes into the box body 11 is arranged on the first screw conveyor 3. The shoveling mechanism 2 and the The first screw conveyors 3 are connected to each other and hinged with the traveling car body 1 through the connecting arm 5. When the traveling car body 1 drives the shoveling mechanism 2 to push forward, the hinged connection can automatically adjust the thickness of the shoveled mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com