Thin type floor heating system mounting structure

A technology for installation structure and floor heating, which is applied to heating methods, building structures, hot water central heating systems, etc. It can solve the problems of high building floor loss, slow construction progress, and large energy consumption, etc., and achieve the reduction of building floor height loss , reduce construction time, and reduce the effect of high energy consumption operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

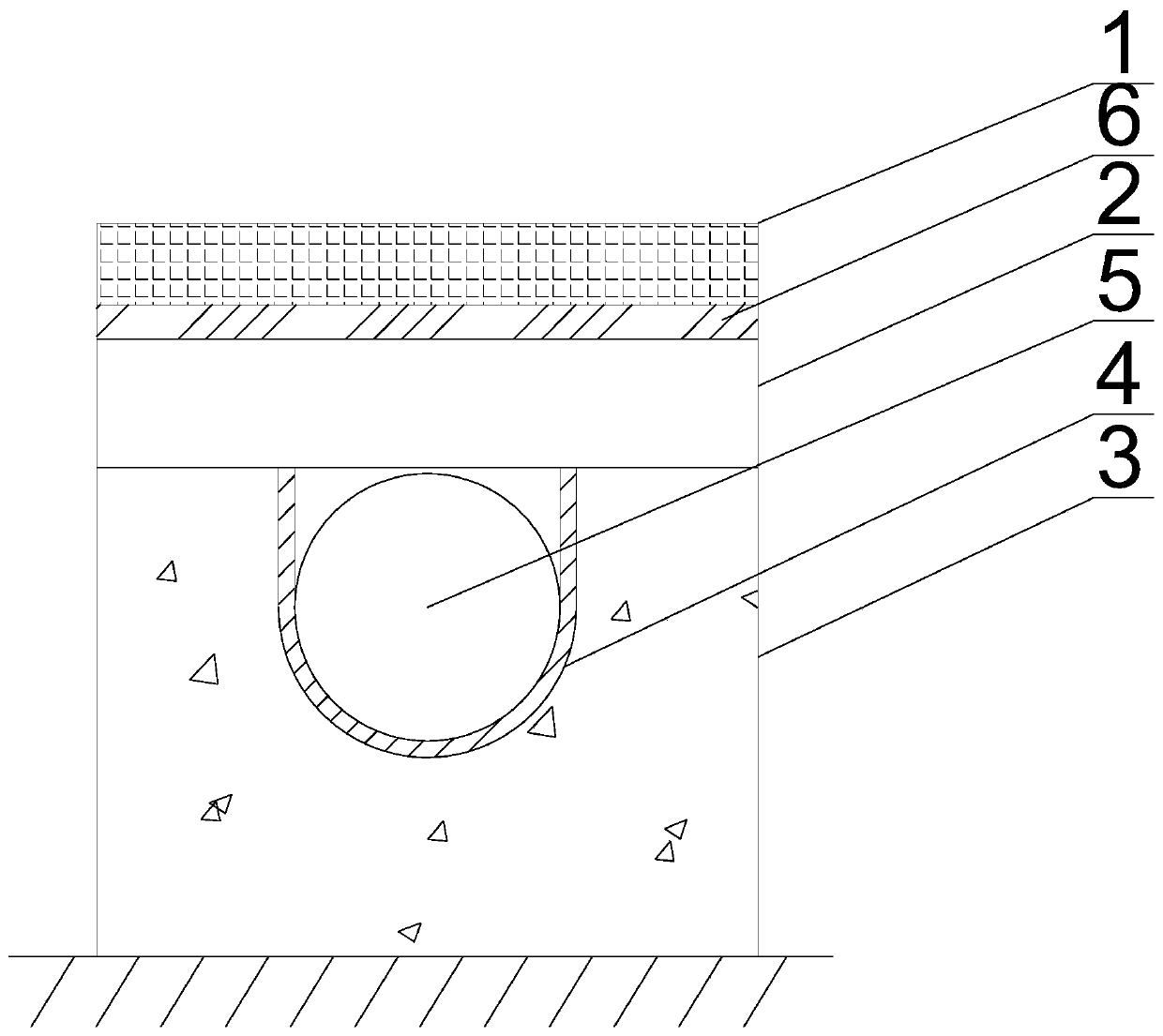

[0024] A thin floor heating installation structure, comprising a floor decoration layer 1, a heat dissipation plate 2, and an insulation layer 3 arranged sequentially from top to bottom, the heat insulation layer 3 is arranged on the concrete floor surface layer, and the heat dissipation plate 2 is provided with There are several U-shaped grooves 4, and the U-shaped grooves 4 are embedded in the insulation layer 3. The floor heating water pipes 5 are arranged in the U-shaped grooves 4. The material of the ground decoration layer 1 is a ceramic sheet, and the ground decoration layer 1 is bonded on the heat dissipation plate 2 through the heating special adhesive 6, and the heat dissipation plate 2 is covered on the insulation layer 3. The heating special adhesive 6 includes the following components in parts by weight: special cement 52 4 parts, 4 parts of quartz sand, 8 parts of cellulose ether, 6 parts of redispersible latex powder, 6 parts of plasticizer and 4 parts of starch ...

Embodiment 2

[0027] In this embodiment, on the basis of Embodiment 1, further, the firing press for the ground decoration layer 1 is 10,000 tons, and the firing temperature is 1230°C. machine, the firing temperature of 6000-7000 ℃, the density and compression resistance of the ceramic thin plate fired by the present invention is stronger than that of traditional ceramic tiles, so the thermal conductivity is higher, and the thickness is only 4-6mm, compared with traditional ceramic tiles. The tiles are lighter and thinner, which can reduce the difficulty of construction during the construction process, reduce energy consumption, and save costs.

Embodiment 3

[0029] In this embodiment, on the basis of Embodiment 1, further, the special heating adhesive 6 includes the following components in parts by weight: 51 parts of special cement, 4 parts of quartz sand, 9 parts of cellulose ether, redispersible 8 parts of latex powder, 7 parts of plasticizer and 4 parts of starch ether. Compared with cement mortar, the heating adhesive is used in less amount, faster in forming, can effectively shorten construction time, improve construction efficiency, and is thicker than cement mortar The mortar is much thinner, which is beneficial to improve the heating efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com