Preparation method of composite flocculant for wastewater purification

A composite flocculant and polymer flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. , the effect of reducing secondary biochemical pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

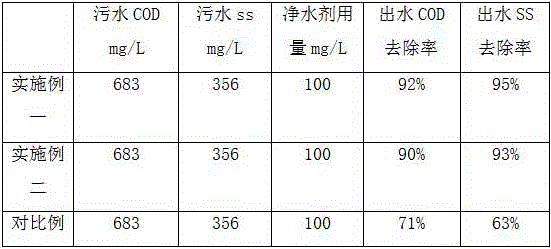

Examples

Embodiment 1

[0018] The raw materials of the composite flocculant in this embodiment are proportioned in parts by weight as follows: modified bentonite 32, polymer flocculant 18, tripotassium phosphate 5, calcium sulfate 6.

[0019] Prepare the raw materials according to the above weight ratio; mix homogeneously, put the modified bentonite and polymer flocculant into a high-speed homomixer and mix them, and observe the mixed particle size distribution under a 1000 times microscope after a certain period of time, and the mixing degree is higher than 98. % is qualified.

[0020] Load tripotassium phosphate and calcium sulfate into the ball mill, start the machine for 30 minutes, add the mixed materials in batches after the above time, and ball mill for 60 minutes to obtain the water purifying agent.

[0021] Among them, the polymer flocculant in the raw material is prepared by the following process:

[0022] Below 40°C, gradually add epichlorohydrin to dimethylamine, and then add modifier t...

Embodiment 2

[0026] The raw materials of the composite flocculant in this embodiment are proportioned in parts by weight as follows: modified bentonite 40, polymer flocculant 24, tripotassium phosphate 12, calcium sulfate 11.

[0027] Prepare the raw materials according to the above weight ratio; mix homogeneously, put the modified bentonite and polymer flocculant into a high-speed homomixer and mix them, and observe the mixed particle size distribution under a 1000 times microscope after a certain period of time, and the mixing degree is higher than 98. % is qualified.

[0028] Load tripotassium phosphate and calcium sulfate into the ball mill, start the machine for 30 minutes, add the mixed materials in batches after the above time, and ball mill for 90 minutes to obtain the water purifying agent.

[0029] Among them, the polymer flocculant in the raw material is prepared by the following process:

[0030] Below 40°C, gradually add epichlorohydrin to dimethylamine, and then add modifier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com