Fiber division method of silk fibroin fibers

A silk fiber and fiber technology, applied in the field of nanomaterial preparation, can solve problems such as inability to mass produce, reduce production efficiency, and increase process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

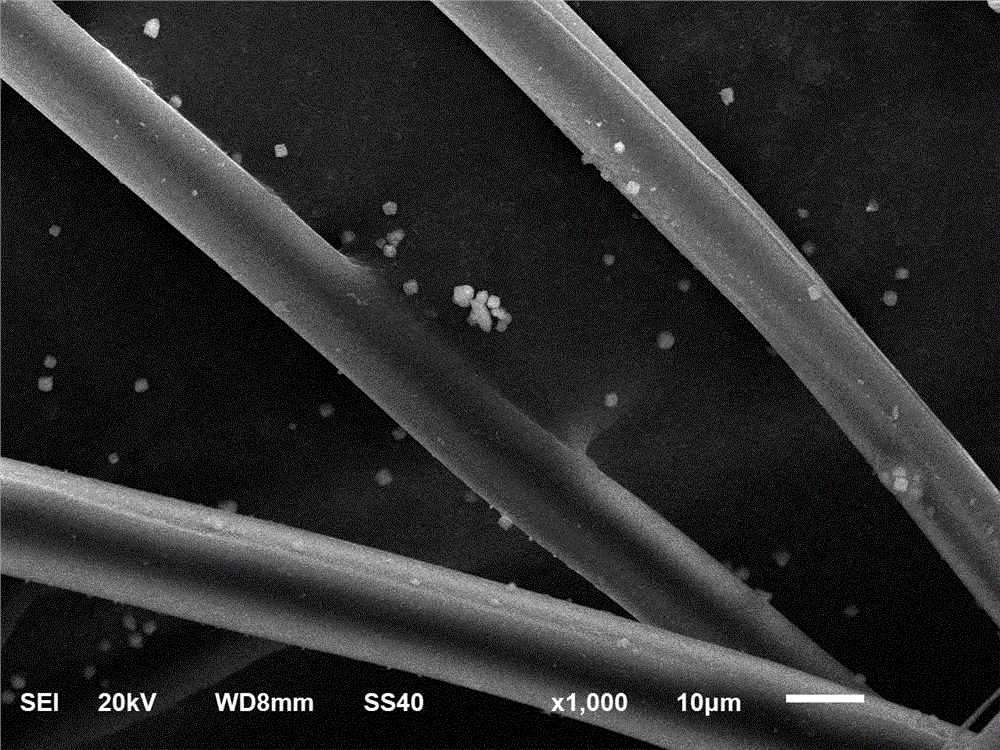

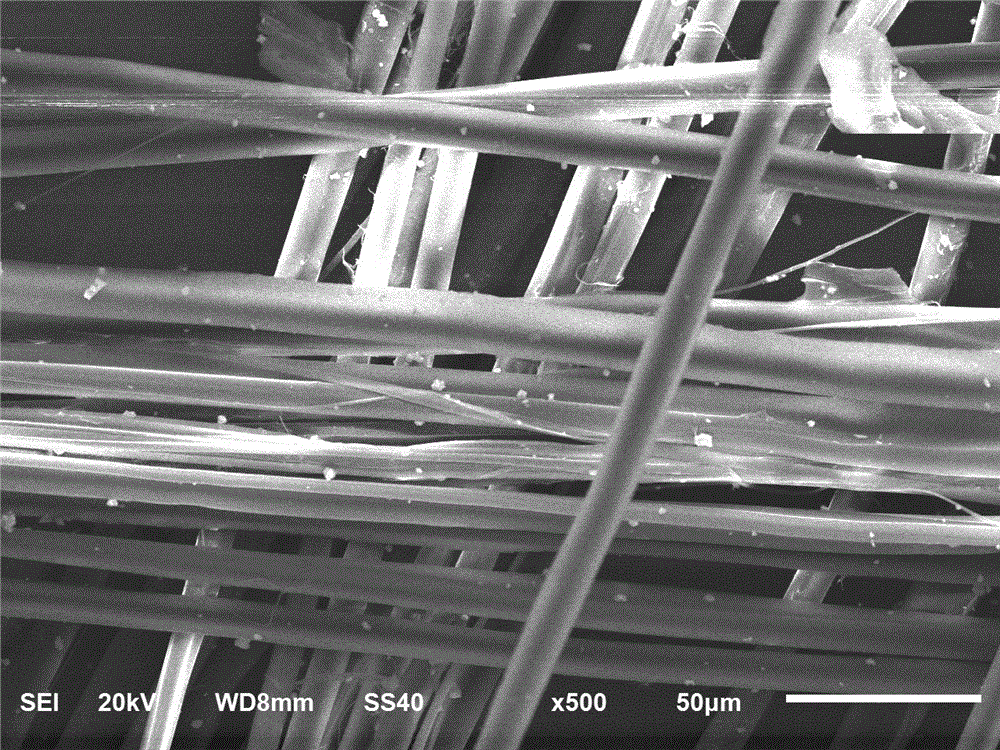

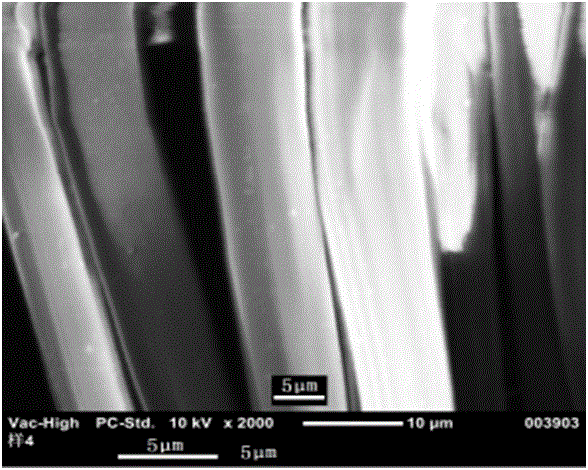

[0032] Configure the soaking solution, the soaking solution is a mixed aqueous solution composed of 0.05% sodium carbonate and 0.05% trisodium phosphate, then heat the soaking solution so that the temperature of the soaking solution is maintained at 40 ° C, and the raw silk fiber in the comparative example After soaking in the soaking liquid for 1 hour, take it out and dry to obtain soaked fibers to be treated by ultrasonic fiber splitting. Place the soaked fiber in the aqueous solution and use the same conditions as in the comparative example to carry out ultrasonic fiber splitting treatment. After the treatment, the silk fiber is scanned by electron microscope to obtain Figure 5 ,From Figure 5 It can be seen that the silk fibroin fibers have basically been transformed into nano silk fibres, the conversion rate is 70%, and the size of the formed silk fibroin nanofibers is 50nm-300nm.

[0033] In addition, in this example, X-ray diffraction tests were performed on the raw s...

Embodiment 2

[0036] Basically consistent with Example 1, the difference is that the concentrations of sodium carbonate and trisodium phosphate are 0.1%, the temperature of the soaking solution is 35 ° C, and the soaking time is 3 hours. After the treatment, the silk fiber is scanned by electron microscope to obtain Figure 9 ,From Figure 9 It can be seen that the silk fibroin fibers have basically been transformed into nano silk fibres, the conversion rate is 75%, and the size of the formed silk fibroin nanofibers is 50nm-300nm.

Embodiment 3

[0038] Basically consistent with Example 1, the difference is that the concentration of sodium carbonate and trisodium phosphate is 0.4%, the temperature of the soaking solution is 50 ° C, and the soaking time is 5 hours. After the treatment, the silk fiber is scanned by an electron microscope to obtain Figure 10 ,From Figure 10 It can be seen that the silk fibroin fibers have basically been transformed into nano silk fibres, the conversion rate is 80%, and the size of the formed silk fibroin nanofibers is 50nm-300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com