Slurry for loudspeaker cone paper

A speaker and drum paper technology, which is applied in the field of slurry for speaker drum paper, can solve the problems of high cost, achieve soft sound quality, high damping, and improve mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

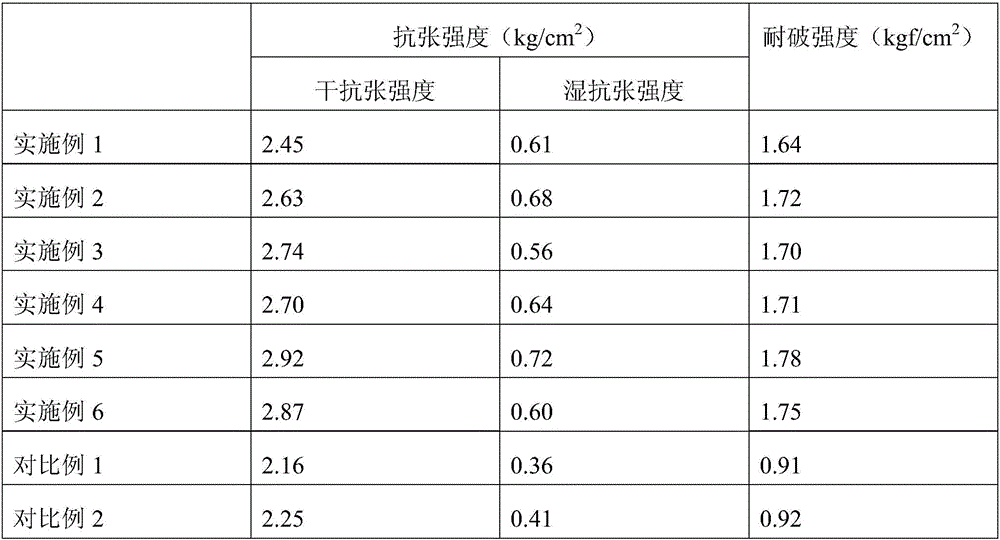

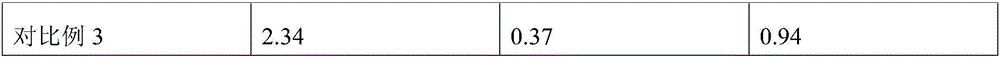

Examples

Embodiment 1

[0032] A slurry for loudspeaker drum paper, which is mainly formed by mixing and stirring the following raw materials in parts by weight: 45 parts of natural kraft softwood pulp, 15 parts of sisal hemp, 10 parts of cotton pulp, 10 parts of kapok, 0.3 parts of bulletproof fiber, 0.1 parts of wool, 0.05 parts of glass fiber, 2 parts of dye, 1 part of table salt, 3 parts of hydroxyethyl cellulose waterproofing agent, 3 parts of hardener, 3 parts of epoxy resin toughening agent, 3 parts of aluminum sulfate regulator, polybias 0.5 parts of potassium phosphate, 0.5 parts of polyethylene oxide, 0.5 parts of urea-formaldehyde resin, 0.2 parts of chitin and 0.2 parts of pineapple fiber. The hardener is a mixture of monochloroacetic acid and trimethyl phosphate at a ratio of 1:0.2.

Embodiment 2

[0034]A slurry for speaker drum paper, which is mainly formed by mixing and stirring the following raw materials in parts by weight: 65 parts of bleached kraft softwood pulp, 30 parts of sisal, 20 parts of cotton pulp, 20 parts of kapok, 1 part of bulletproof fiber, 0.8 parts of wool, 0.5 parts of glass fiber, 8 parts of dye, 5 parts of table salt, 8 parts of sodium metasilicate waterproofing agent, 8 parts of hardener, 8 parts of phenolic resin toughening agent, 8 parts of polyaluminum chloride regulator, polyvinyl chloride 5 parts of potassium phosphate, 5 parts of polyethylene oxide, 5 parts of urea-formaldehyde resin, 3 parts of chitin and 3 parts of pineapple fiber, wherein the hardener is a mixture of monochloroacetic acid and trimethyl phosphate at a ratio of 1:0.8 mixture.

Embodiment 3

[0036] A slurry for speaker drum paper, which is mainly formed by mixing and stirring the following raw materials in parts by weight: 50 parts of natural kraft softwood pulp, 20 parts of sisal hemp, 12 parts of cotton pulp, 12 parts of kapok, 0.4 part of bulletproof fiber, 0.2 parts of wool, 0.1 parts of glass fiber, 3 parts of dye, 2 parts of table salt, 4 parts of sodium metasilicate waterproofing agent, 4 parts of hardener, 4 parts of unsaturated polyester resin toughening agent, 4 parts of aluminum sulfate regulator, poly 1 part of potassium metaphosphate, 1 part of polyethylene oxide, 1 part of urea-formaldehyde resin, 0.5 part of chitin and 0.5 part of pineapple fiber, wherein the hardener is a mixture of monochloroacetic acid and diethyl oxalate at a ratio of 1:0.2 mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com