Production method and production equipment of potassium polymetaphosphate

A technology of potassium polymetaphosphate and production method, applied in the field of production method and production equipment of potassium polymetaphosphate, can solve the problems of reducing the purity of potassium polymetaphosphate, affecting quality, etc., and achieves good heat resistance, reduced impact, high corrosion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

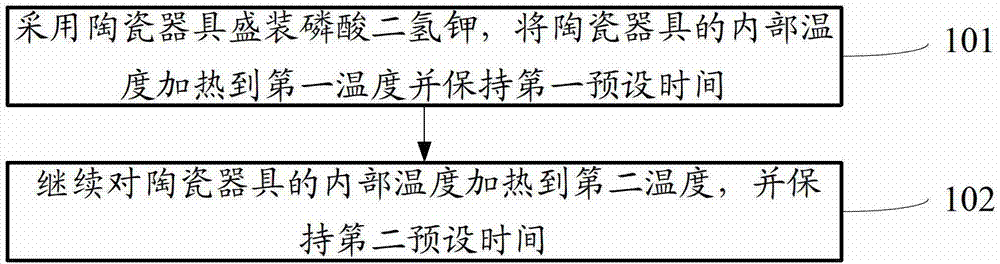

[0037] Present embodiment 1 provides a kind of production method of potassium polymetaphosphate, as figure 1 As shown, the main processing steps include:

[0038] Step 101: Using ceramic utensils to contain potassium dihydrogen phosphate, heating the internal temperature of the ceramic utensils to a first temperature, and maintaining it for a first preset time;

[0039] Step 102: Continue to heat the internal temperature of the ceramic utensil to a second temperature and keep it for a second preset time.

[0040] In the preparation process of potassium polymetaphosphate, ceramic utensils are used to hold potassium dihydrogen phosphate, and the internal temperature of the ceramic utensils is first heated to the first temperature, and kept for the first preset time. In this step, as the temperature rises, , the solid potassium dihydrogen phosphate gradually softens into a liquid state, and the liquid potassium dihydrogen phosphate gradually removes the crystal water inside the ...

Embodiment 2

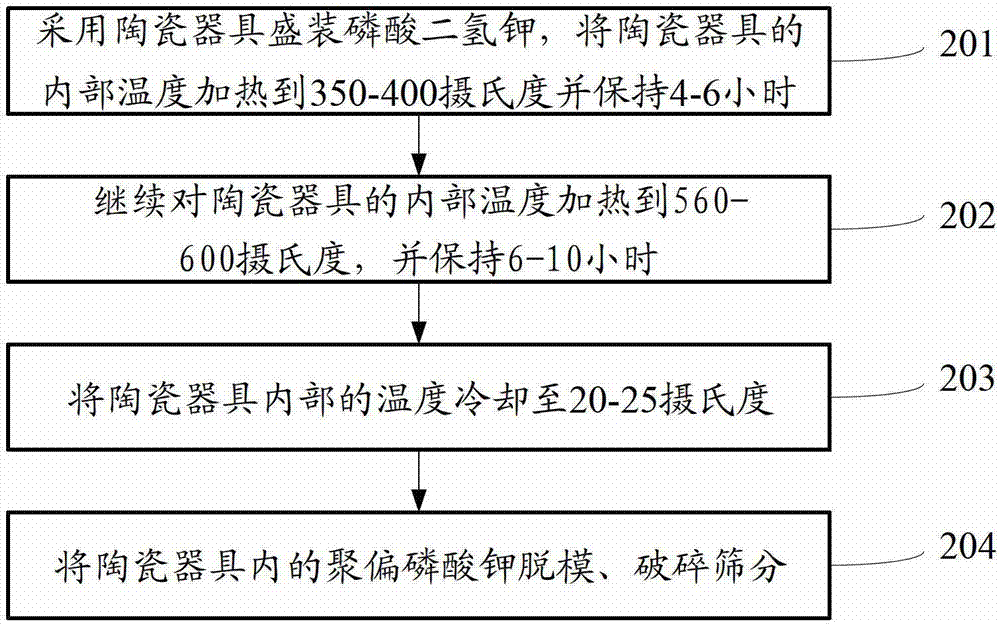

[0043] Present embodiment 2 provides a kind of preferred embodiment of the production method of potassium polymetaphosphate on the basis of embodiment 1, as figure 2 As shown, the main processing steps include:

[0044] Step 201: Use ceramic utensils to hold potassium dihydrogen phosphate, heat the internal temperature of the ceramic utensils to a first temperature, and the first temperature is 350-400 degrees Celsius, and keep it for a first preset time, and the first preset temperature is Set the time to 4-6 hours.

[0045] Heating the temperature inside the ceramic ware to the first temperature refers to heating the temperature from normal temperature to the first temperature. The purpose of this step is to change the potassium dihydrogen phosphate in the ceramic ware from solid to liquid, and to change it into liquid phosphoric acid. Potassium dihydrogen will gradually remove the water of crystallization in the molecule. Specifically, the first temperature to be heated ...

Embodiment 3

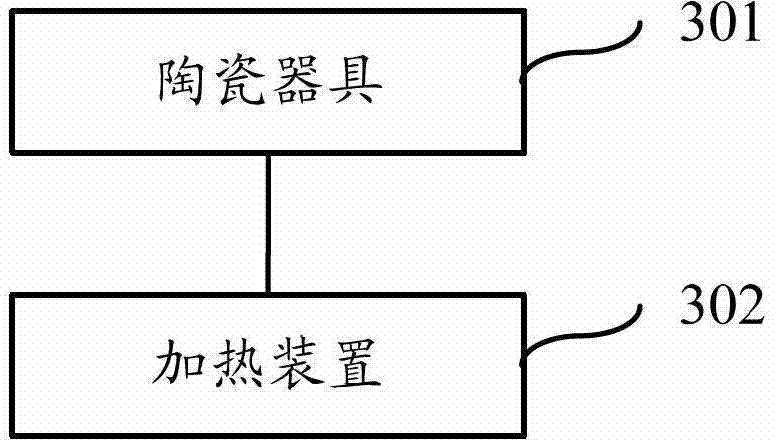

[0076] Present embodiment 3 provides a kind of production equipment of potassium polymetaphosphate for the production method of potassium polymetaphosphate provided in embodiment 1, such as image 3 As shown, the device includes: a ceramic utensil 301 and a heating device 302;

[0077] Ceramic ware 301 for containing potassium dihydrogen phosphate;

[0078] The heating device 302 is used to heat the internal temperature of the ceramic utensil containing potassium dihydrogen phosphate to a first temperature and maintain the first preset time; continue to heat the internal temperature of the ceramic utensil to a second temperature and maintain Second preset time.

[0079] Using the production equipment of potassium polymetaphosphate of the present embodiment, potassium dihydrogen phosphate is placed in the ceramic utensil 301, and the ceramic utensil is heated by the heating device 302, so that the potassium dihydrogen phosphate in the ceramic utensil 301 can be removed from cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com