Method for producing anti-crushing granular sodium tripolyphosphate

A technology of sodium tripolyphosphate and production method, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of inability to guarantee dissolution rate results, increased humidification, sieving, low particle structure strength, etc. Risk of scalding and burns, ensuring dissolution rate, and improving work comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First add 5 tons of water to the neutralization pot, add 4.5 tons of industrial grade soda ash, stir to completely dissolve the soda ash, and slowly add 6.06 tons of 85% phosphoric acid and 3.5 tons of solid sodium carbonate to react under stirring. Steam is heated to the system temperature of 40°C, 40kg of sodium hexametaphosphate and 40kg of potassium polymetaphosphate are added to the neutralization pot after compatibility, the reaction is finely filtered, and then sent to the drying tower to dry at 130°C by countercurrent drying, and sent to the polymerization furnace at 210°C , 5Hz frequency, polymerization 50min to generate sodium tripolyphosphate.

[0027] The overall reaction process can be represented by the following reaction formula:

[0028] 6H 3 PO 4 +5Na 2 CO 3 →4Na 2 HPO 4 +2NaH 2 PO 4 +5CO 2 ↑+5H 2 o

[0029] NaH 2 PO 4 +2Na 2 HPO 4 →Na 5 P 3 o 10 +2H 2 o

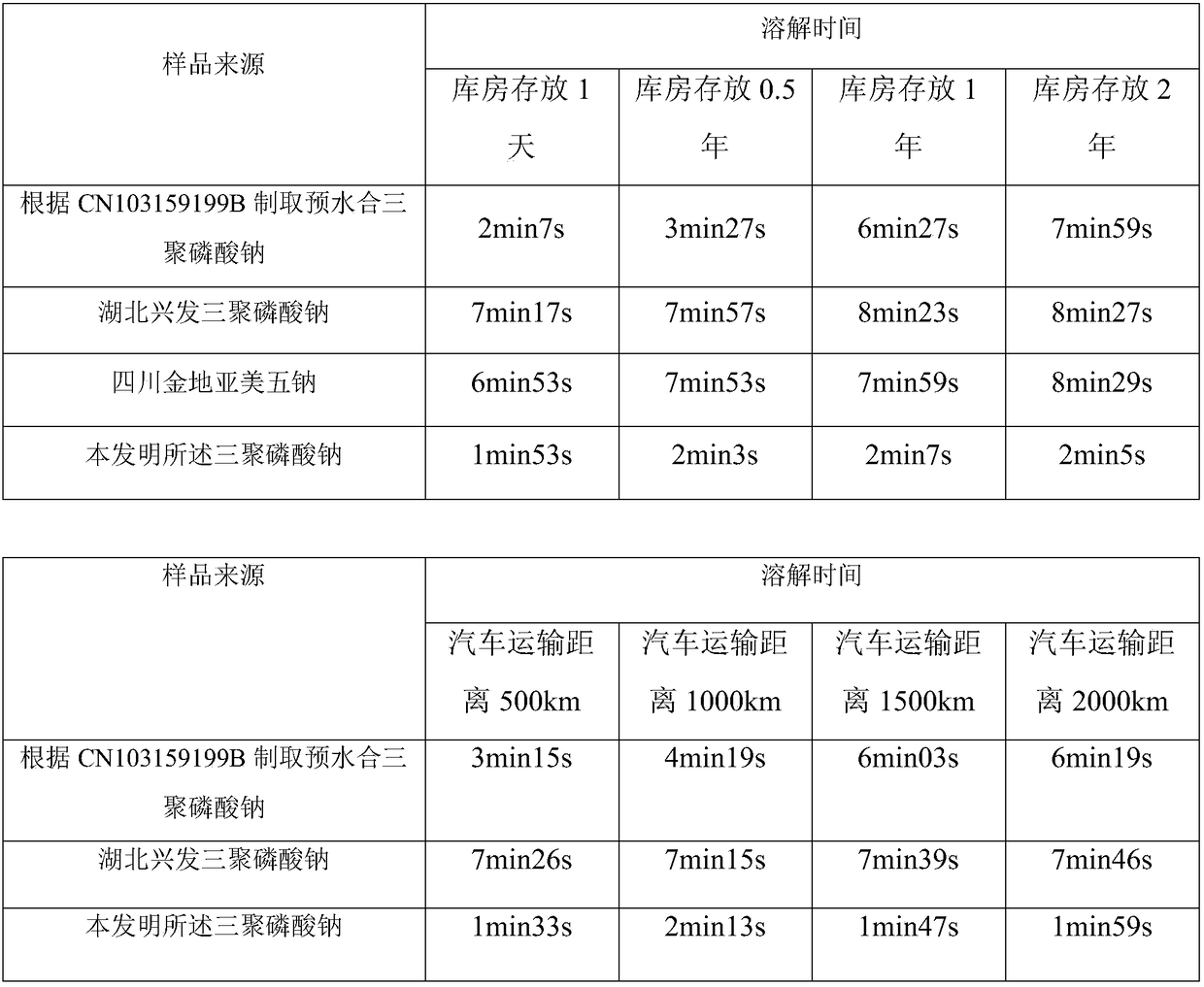

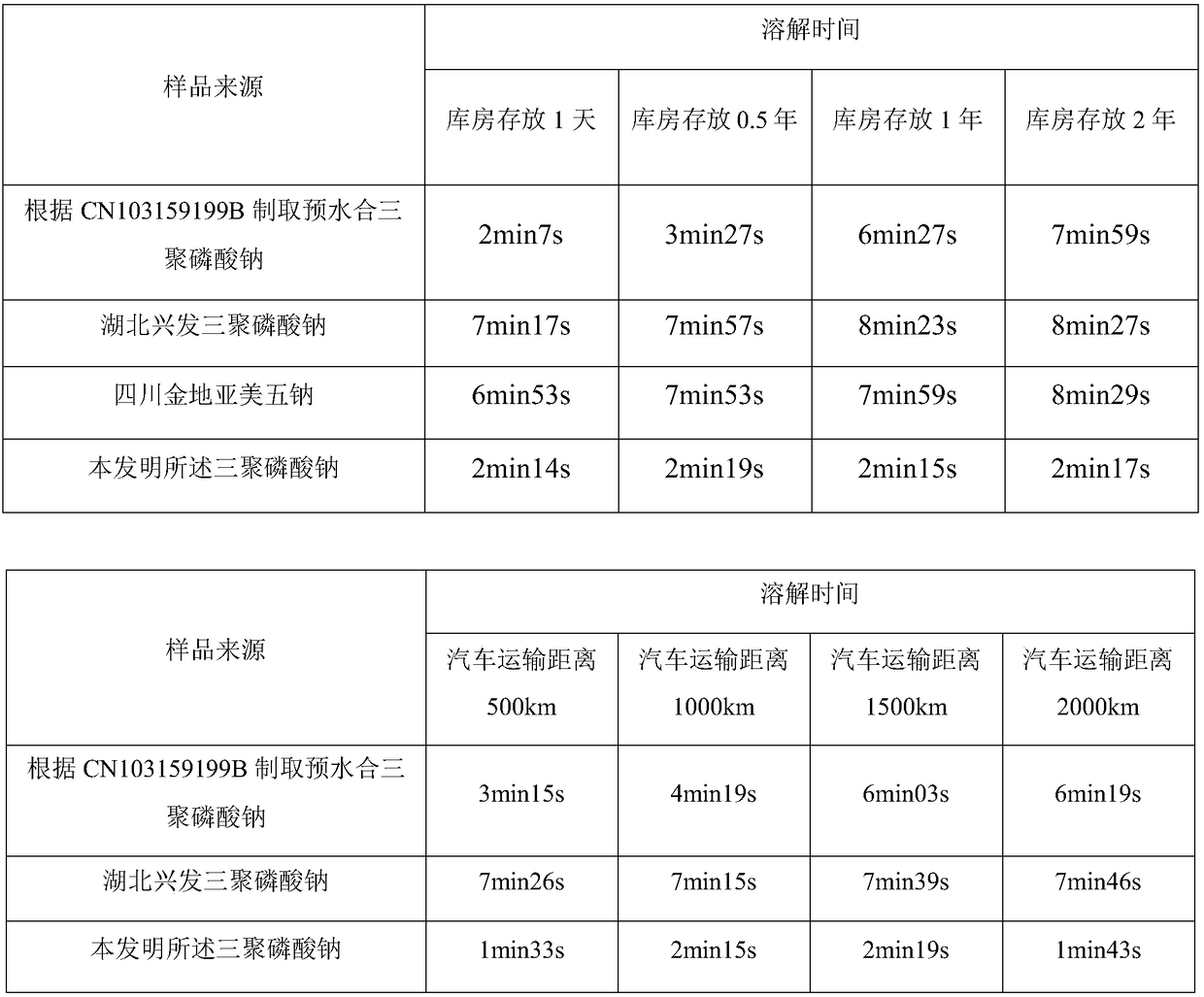

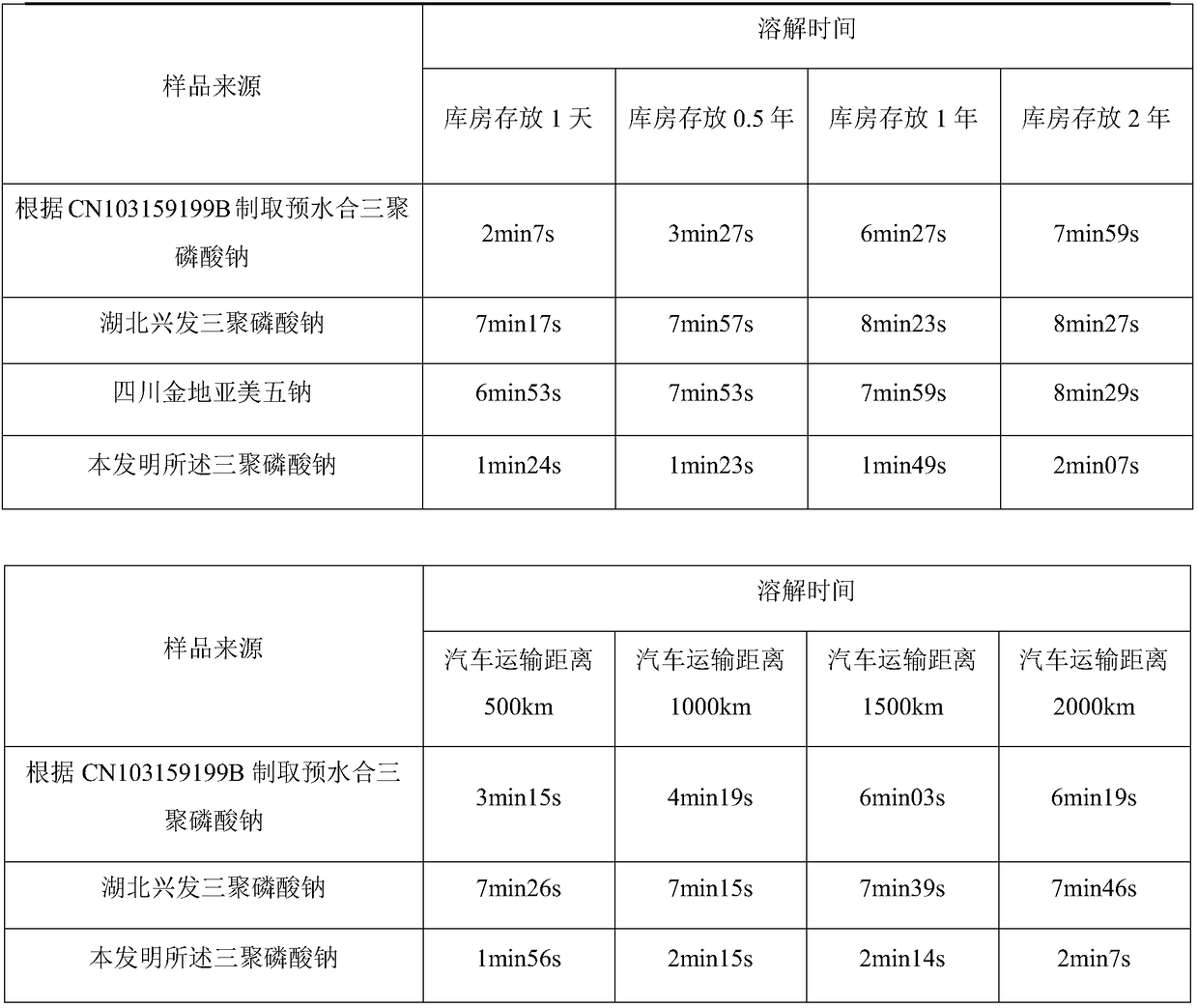

[0030] Determination of dissolution rate:

[0031] Keep the temperature of th...

Embodiment 2

[0034] Add 15 tons of water into the neutralization pot, add 4.5 tons of industrial-grade soda ash, stir to completely dissolve the soda ash, and slowly add 6.015 tons of 85% phosphoric acid and 3.5 tons of solid sodium carbonate to react under stirring. Steam is heated to the system temperature of 50°C, 55kg of sodium hexametaphosphate and 55kg of potassium polymetaphosphate are added to the neutralization pot after compatibility, the reaction is refined and filtered, then sent to the drying tower to dry at 140°C by countercurrent drying, and sent to the polymerization furnace at 200°C , 6Hz frequency, polymerization 60min to generate sodium tripolyphosphate.

[0035] Determination of dissolution rate:

[0036] Keep the temperature of the environment and water at 20°C, put 10g of sample into the beaker with 100ml of water in a 250ml beaker at a stirring speed of 1200rmp, observe the dissolution phenomenon until no visible white solid is the end point of dissolution. Record t...

Embodiment 3

[0039] Add 15 tons of water into the neutralization pot, add 3.5 tons of industrial grade soda ash, stir to completely dissolve the soda ash, and slowly add 6.107 tons of 85% phosphoric acid and 4.5 tons of solid sodium carbonate to react under stirring. Steam is heated to the system temperature of 450°C, 70kg of sodium hexametaphosphate and 70kg of potassium polymetaphosphate are added to the neutralization pot after compatibility, the reaction is refined and filtered, then sent to the drying tower to dry at 120°C by countercurrent drying, and sent to the polymerization furnace at 220°C , 4Hz frequency, polymerization for 55min to generate sodium tripolyphosphate.

[0040] Determination of dissolution rate:

[0041] Keep the temperature of the environment and water at 20°C, put 10g of sample into the beaker with 100ml of water in a 250ml beaker at a stirring speed of 1200rmp, observe the dissolution phenomenon until no visible white solid is the end point of dissolution. Rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com