Preparation method of porous raw material for aluminum nitride crystal growth

A technology of crystal growth and aluminum nitride, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve problems such as unfavorable raw material volatilization crystal growth, and achieve the effects of low cost, simple equipment and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

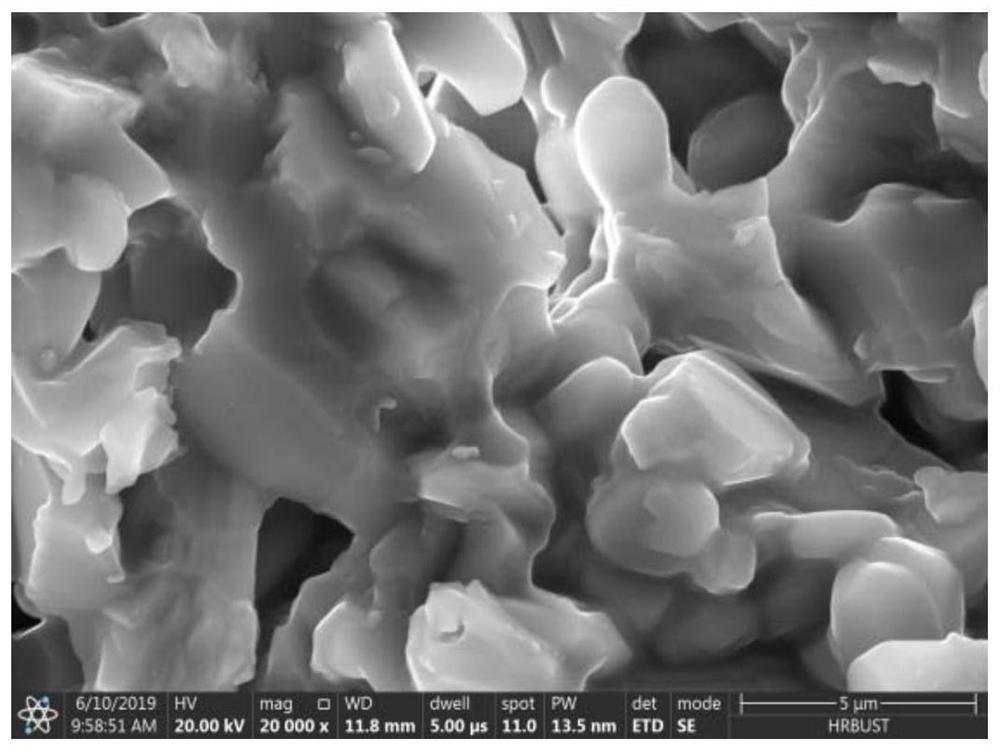

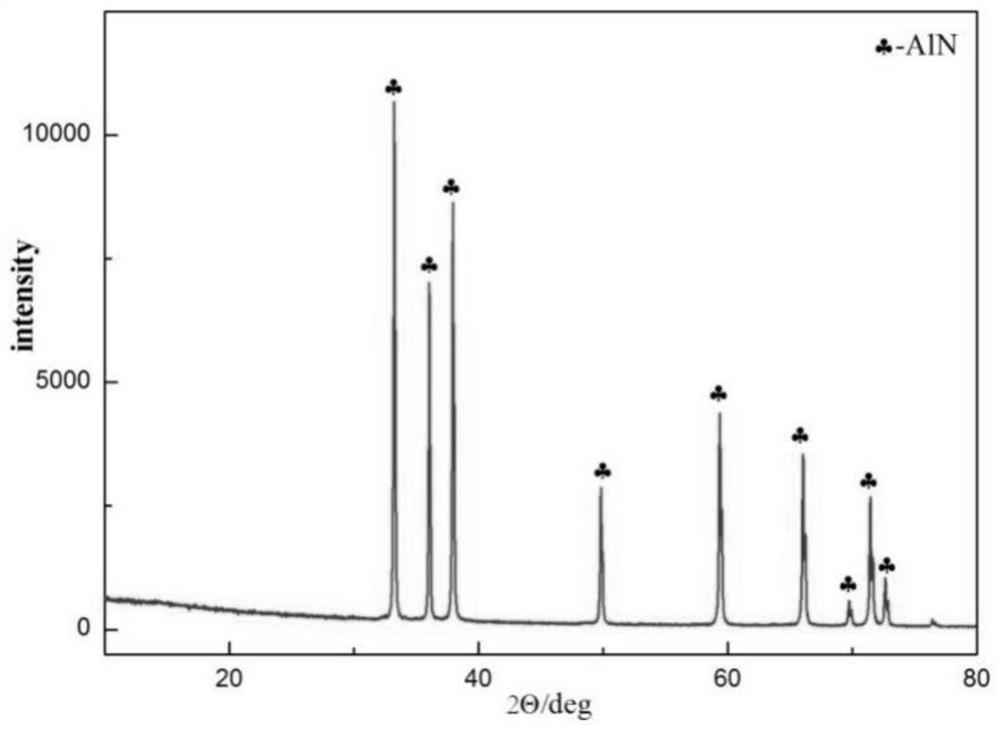

Image

Examples

Embodiment 1

[0023] This embodiment provides a method for preparing a porous raw material for aluminum nitride crystal growth, comprising the following steps:

[0024] Step 1, immersing the aluminum nitride powder body in mass concentration of 2% Al(H 2 PO 4 ) 3 In the solution, the soaking time is 1h, and the aluminum nitride powder after treatment has strong hydrolysis resistance;

[0025] Step 2. Slowly add sodium alginate into deionized water and stir until the sodium alginate is completely dissolved to obtain a sodium alginate solution with a mass concentration of 0.2%. The anti-hydrolysis pretreated aluminum nitride powder is added to the sodium alginate solution, stirred at 150rpm for 1h, and then ball milled at 60rpm for 4h to obtain a mixed slurry. Ball milling can reduce the particle size of the powder and make the slurry more uniform;

[0026] Step 3. The obtained mixed slurry is poured into the mold, and the calcium chloride solution with a molar concentration of 0.5mol / L is...

Embodiment 2

[0032] This embodiment provides a method for preparing a porous raw material for aluminum nitride crystal growth, comprising the following steps:

[0033] Step 1, immersing the aluminum nitride powder body in mass concentration of 2% Al(H 2 PO 4 ) 3 In the solution, the soaking time is 2 hours, and the aluminum nitride powder after treatment has strong hydrolysis resistance;

[0034] Step 2. Slowly add sodium alginate into deionized water and stir until the sodium alginate is completely dissolved to obtain a sodium alginate solution with a mass concentration of 0.2%. The anti-hydrolysis pretreated aluminum nitride powder is added to the sodium alginate solution, stirred at 200rpm for 0.5h, and then ball milled at 70rpm for 5h to obtain a mixed slurry. Ball milling can make the particle size of the powder smaller and make the slurry more uniform;

[0035] Step 3. The obtained mixed slurry is poured into the mold, and the calcium chloride solution with a molar concentration o...

Embodiment 3

[0039] This embodiment provides a method for preparing a porous raw material for aluminum nitride crystal growth, comprising the following steps:

[0040] Step 1, immersing the aluminum nitride powder body in a mass concentration of 6% Al(H 2 PO 4 ) 3 In the solution, the soaking time is 3 hours, and the aluminum nitride powder after treatment has strong hydrolysis resistance;

[0041] Step 2. Slowly add sodium alginate into deionized water and stir until the sodium alginate is completely dissolved to obtain a sodium alginate solution with a mass concentration of 0.2%. Add the anti-hydrolysis pretreated aluminum nitride powder into the sodium alginate solution, stir at 300rpm for 1h, and then ball mill at 100rpm for 5h to obtain the mixed slurry. Ball milling can make the particle size of the powder smaller and make the slurry more uniform;

[0042] Step 3. The obtained mixed slurry is poured into the mold, and the calcium chloride solution with a molar concentration of 3mol / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com