Preparation method of porous aluminum nitride material

An aluminum nitride and powder technology is applied in the field of preparation of porous aluminum nitride materials to achieve the effects of simple equipment, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

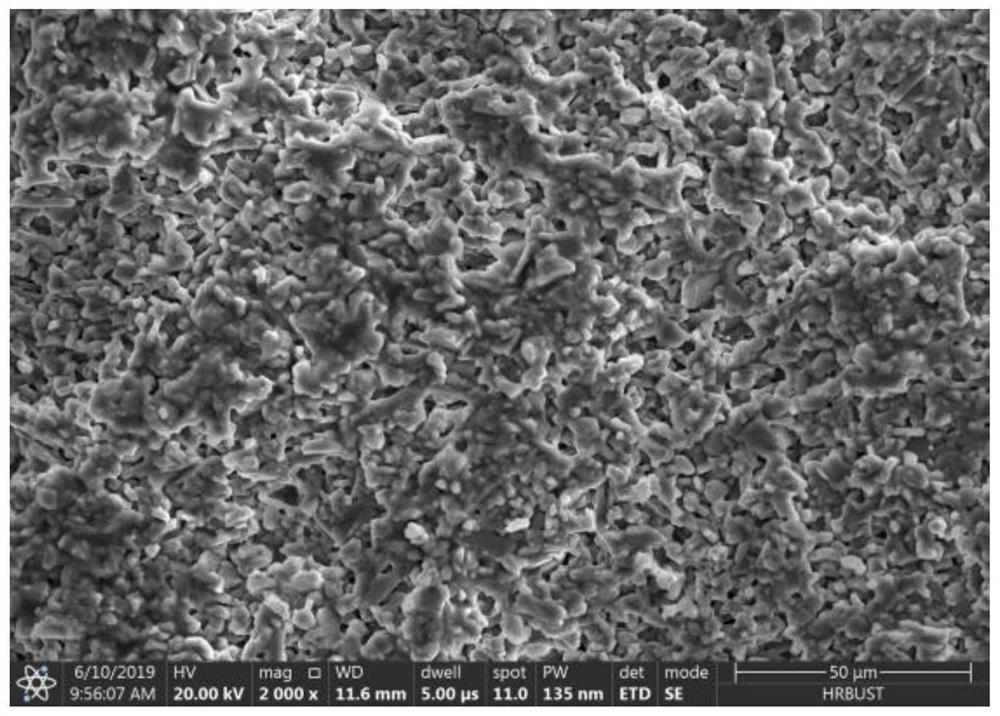

Image

Examples

specific Embodiment approach 1

[0023] A method for preparing a porous aluminum nitride material, comprising the steps of:

[0024] Step 1, adding a certain quality of Al(H 2 PO 4 ) 3 solution, then add it to a ball mill for ball milling, and then dry it in a vacuum to obtain pretreated aluminum nitride powder for use;

[0025] Step 2. Add egg white protein to deionized water, stir evenly to obtain egg white protein solution, and set aside;

[0026] Step 3. According to a certain volume ratio, weigh the pretreated aluminum nitride powder, ovalbumin solution, dispersant, and stabilizer, and add the weighed aluminum nitride powder to the egg under stirring conditions. In the albumin solution, after stirring for a certain period of time, add a dispersant, continue stirring for a certain period of time, add a stabilizer, and continue stirring for a certain period of time to obtain a premix, which is ready for use;

[0027] Step 4. Put the premixed material obtained in step 3 into a ball mill for ball milling...

specific Embodiment approach 2

[0040] A method for preparing a porous aluminum nitride material, comprising the steps of:

[0041] Step 1, adding a certain quality of Al(H 2 PO 4 ) 3 solution, then add it to a ball mill for ball milling, and then dry it in a vacuum to obtain pretreated aluminum nitride powder for use;

[0042] Step 2. Add egg white protein to deionized water, stir evenly to obtain egg white protein solution, and set aside;

[0043]Step 3. According to a certain volume ratio, weigh the pretreated aluminum nitride powder, ovalbumin solution, dispersant, and stabilizer, and add the weighed aluminum nitride powder to the egg under stirring conditions. In the albumin solution, after stirring for a certain period of time, add a dispersant, continue stirring for a certain period of time, add a stabilizer, and continue stirring for a certain period of time to obtain a premix, which is ready for use;

[0044] Step 4. Put the premixed material obtained in step 3 into a ball mill for ball milling,...

specific Embodiment approach 3

[0056] A method for preparing a porous aluminum nitride material, comprising the steps of:

[0057] Step 1, adding a certain quality of Al(H 2 PO 4 ) 3 solution, then add it to a ball mill for ball milling, and then dry it in a vacuum to obtain pretreated aluminum nitride powder for use;

[0058] Step 2. Add egg white protein to deionized water, stir evenly to obtain egg white protein solution, and set aside;

[0059] Step 3. According to a certain volume ratio, weigh the pretreated aluminum nitride powder, ovalbumin solution, dispersant, and stabilizer, and add the weighed aluminum nitride powder to the egg under stirring conditions. In the albumin solution, after stirring for a certain period of time, add a dispersant, continue stirring for a certain period of time, add a stabilizer, and continue stirring for a certain period of time to obtain a premix, which is ready for use;

[0060] Step 4. Put the premixed material obtained in step 3 into a ball mill for ball milling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com