Novel preparation method of esprazole magnesium trihydrate and intermediate thereof

A technology of esomeprazole and omeprazole sulfide, which is applied in the field of chemical drug synthesis and can solve problems such as toxicity, acetonitrile is volatile, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1. condensation reaction, prepares the preparation of omeprazole sulfide (intermediate 1)

[0073] Reaction equation:

[0074]

[0075] (1) Add 102.0kg of 95% ethanol to a 200L reactor, add 6.2kg of medicinal sodium hydroxide under nitrogen protection, and stir to dissolve. Control the temperature of the reaction solution at 15-25°C, add 11.9kg of 2-mercapto-5-methoxybenzimidazole, 15.0kg of Ogilvy chloride (67.87mol) and 0.3kg of potassium iodide in sequence, and slowly raise the temperature to 50°C-55°C ℃, keep warm for 30 minutes;

[0076] (wherein the mol ratio of 2-mercapto-5-methoxybenzimidazole, Ogilvy chloride, sodium hydroxide and potassium iodide is 1:1.02:2.27:0.027; 95% ethanol consumption is 7 times quality of Ogilvy chloride, Or 2-mercapto-5-methoxybenzimidazole 8.8 times the mass).

[0077] (2) Sampling is monitored by TLC method (developing agent ethyl acetate: n-hexane = 1:1) 2-mercapto-5-methoxybenzimidazole spots disappear, the reacti...

Embodiment 2

[0080] Embodiment 2. chiral oxidation reaction prepares esomeprazole

[0081] Reaction equation:

[0082]

[0083] (1) Add 87.7kg of toluene (the amount of toluene is 4 times the mass of omeprazole sulfide) to 21.62kg of intermediate I (containing 64.54mol omeprazole sulfide) obtained in Example 1, and heat up to 50°C After stirring and dissolving completely, transfer it to a 500L reactor, and turn on the nitrogen protection.

[0084] (2) Heat up to 50±3°C, add 169g of purified water and 5.47kg of D-diethyl tartrate, keep warm for 20 minutes, slowly add isopropyl titanate toluene solution dropwise (5.79kg of isopropyl titanate dissolved in 7.4kg Toluene), maintain the temperature of the reaction solution at 50±3°C and stir for 50min to 60min. Wherein, the molar ratio of water, D-diethyl tartrate, isopropyl titanate and omeprazole sulfide is 0.14:0.4:0.3:1.

[0085] (3) Cool down to 15-20°C, and add 2.66kg of triethylamine. Continue to cool down, slowly add cumene hydrop...

Embodiment 3

[0087] Embodiment 3. becomes potassium salt reaction

[0088] Reaction equation:

[0089]

[0090] (1) The esomeprazole reaction liquid of embodiment 2 gained is cooled to below 10 ℃, slowly adds potassium hydroxide methanol solution (5.92kg potassium hydroxide is dissolved in 40kg methanol), separates out solid;

[0091] (2) Heat up to 25-30°C and stir to react for 2 hours. Filtration, the filter cake was beaten with a mixed solution of 14.6kg toluene and 14.6kg methanol for 30 minutes, and filtered;

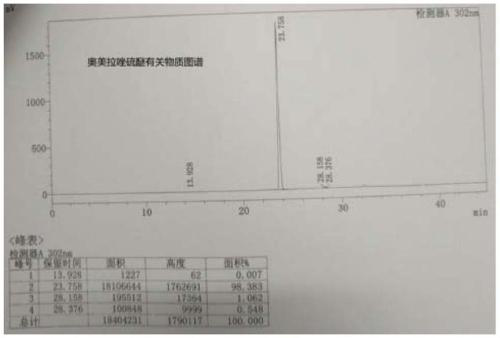

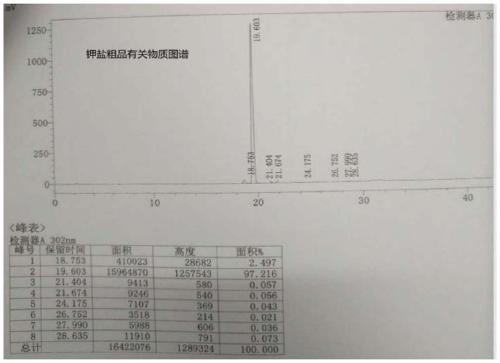

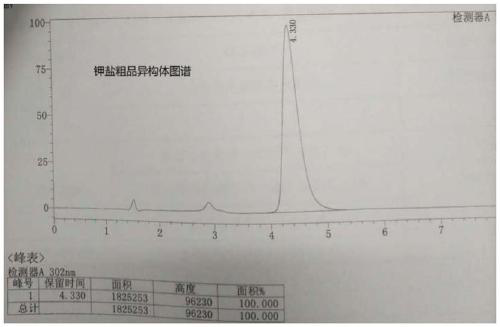

[0092] (3) The filter cake was dried under reduced pressure at 40~45°C to obtain 21.5kg with a purity of 97.216% (see figure 2 ) crude esomeprazole potassium (intermediate 2, containing 20.90 g of esomeprazole potassium, molecular weight 384, ie 54.427 mol), was sampled and submitted for inspection, and entered the refining process in line with the quality control standard of intermediate 2. If unqualified, rework is carried out until it meets the quality control standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com