Device and method for preparing high-performance platinum and platinum-rhodium thermocouple wire

A technology for thermocouple wires and preparation devices, which is applied in the field of preparation devices for platinum and platinum-rhodium thermocouple wires and high-performance platinum and platinum-rhodium thermocouple wires. Problems such as high broken wire rate, achieve good room temperature plasticity, good high temperature plasticity, and simplify processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

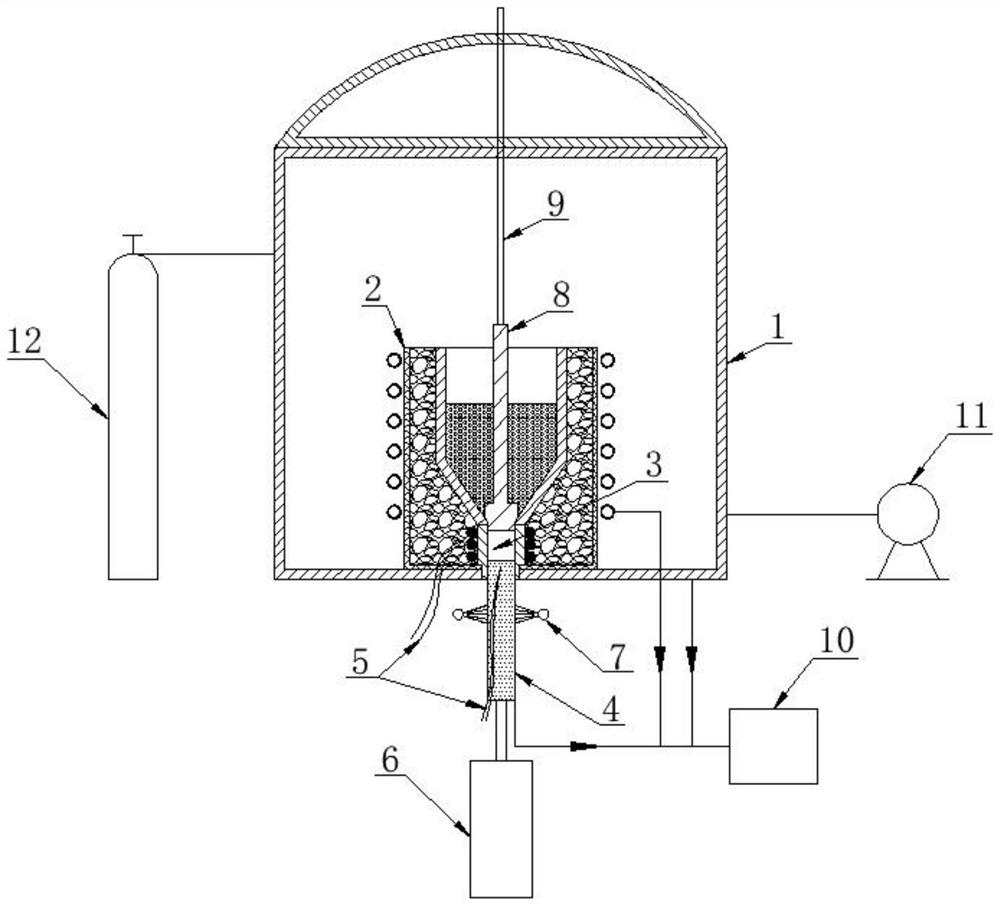

[0045] A preparation method of high-performance platinum and platinum-rhodium thermocouple wire, comprising the steps of:

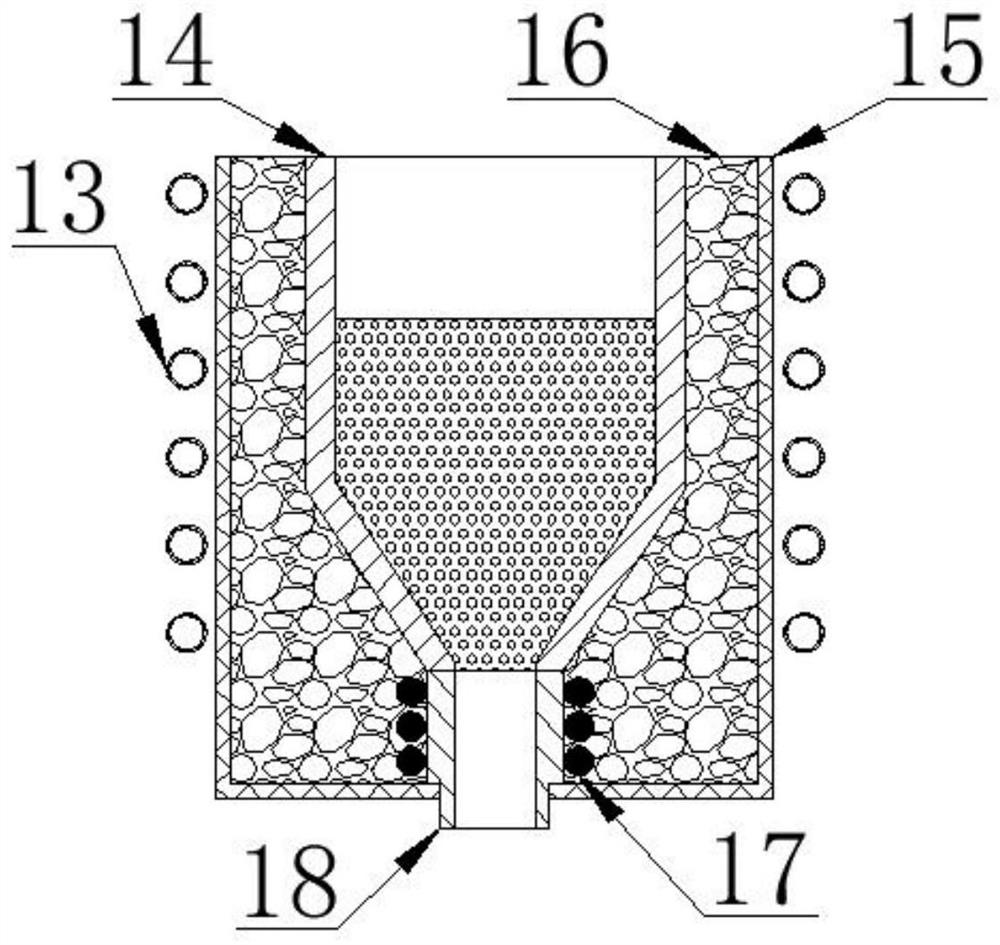

[0046] Step 1, plugging the bottom of the crucible 14 with a stopper rod 8, and then placing the platinum-rhodium alloy material in the crucible 14, the weight of the platinum-rhodium alloy is controlled at 1-4Kg;

[0047] Step 2, close the furnace cover of the reaction furnace 1, open the water cooler 10, increase the power of the induction coil 13 to melt the alloy material in the crucible 14, and simultaneously energize the heating wire 17 to heat the crystallizer 3 to the melting point of the alloy;

[0048] Step 3: Reduce the power of the induction coil 13 to keep the alloy melt in a heat preservation state to ensure uniform composition, and at the same time turn on the vacuum pump 11 to evacuate the inner cavity of the reaction furnace 1 to 1×10 -6 Pa, and then filled with protective gas (argon, helium or nitrogen) to make the internal pressure the ...

Embodiment

[0055] 1) Block the bottom of the zirconia crucible with a zirconia stopper, then place 3kg of prepared pure platinum in the zirconia crucible;

[0056] 2) Close the lid of the reaction furnace, turn on the water cooler, increase the power of the induction coil to 21KW to melt the pure platinum in the crucible, and at the same time energize the tungsten heating wire to raise the temperature of the crystallizer to 1769°C;

[0057] 3) Reduce the power of the induction coil to 16KW to keep the pure platinum melt in a state of heat preservation, and at the same time turn on the vacuum pump to evacuate the inner cavity of the reaction furnace to 1×10 -6 Pa, then filled with protective gas argon to 1.01×10 5 Pa;

[0058] 4) Insert the pure platinum dummy rod into the crystallizer, install the cooling device 20mm away from the lower outlet of the crystallizer, and turn on the cooling device to spray cooling water towards the pure platinum dummy rod, then pull up the pull rod to pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com