Production system for multi-grade crushing and processing of reclaimed rubber

A technology of recycled rubber and production system, which is applied in recycling technology, mechanical material recycling, plastic recycling, etc. It can solve the problems that powder cannot be screened out by magnetic separation, steel wire cannot be separated, and particles are too large.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

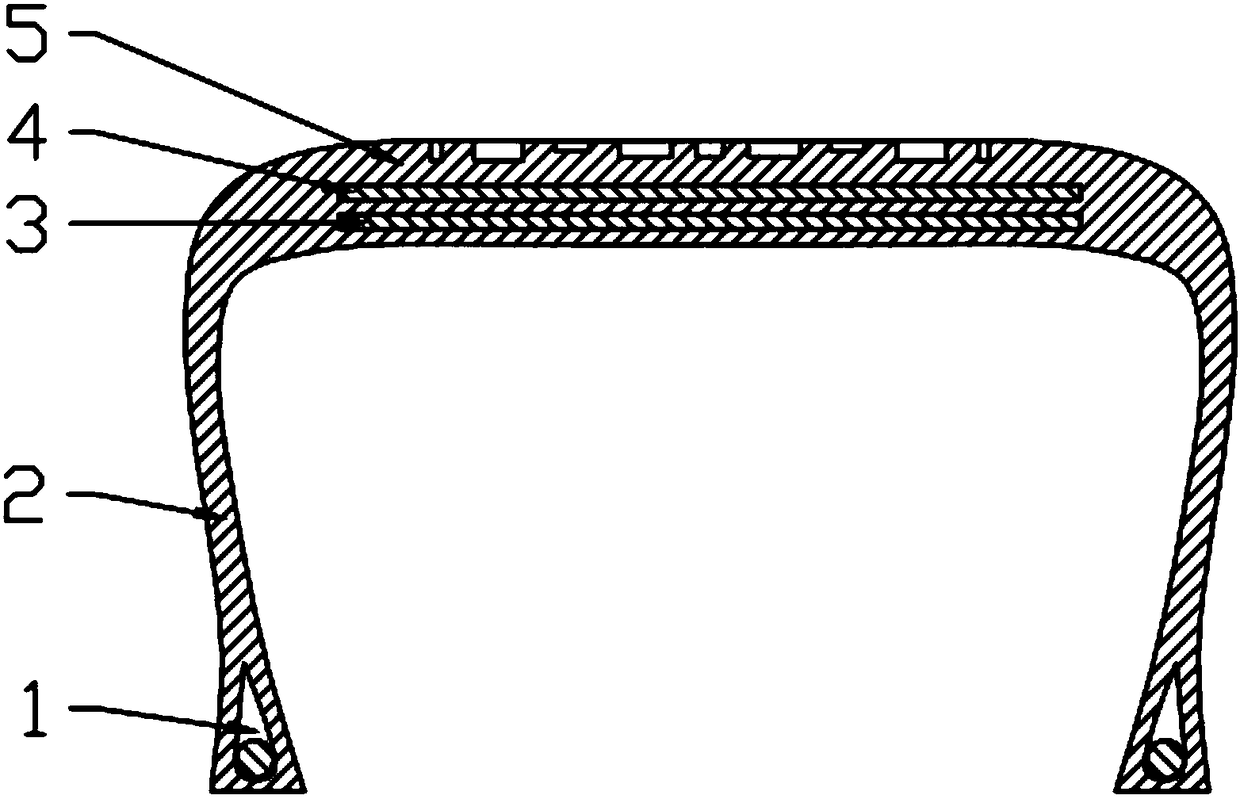

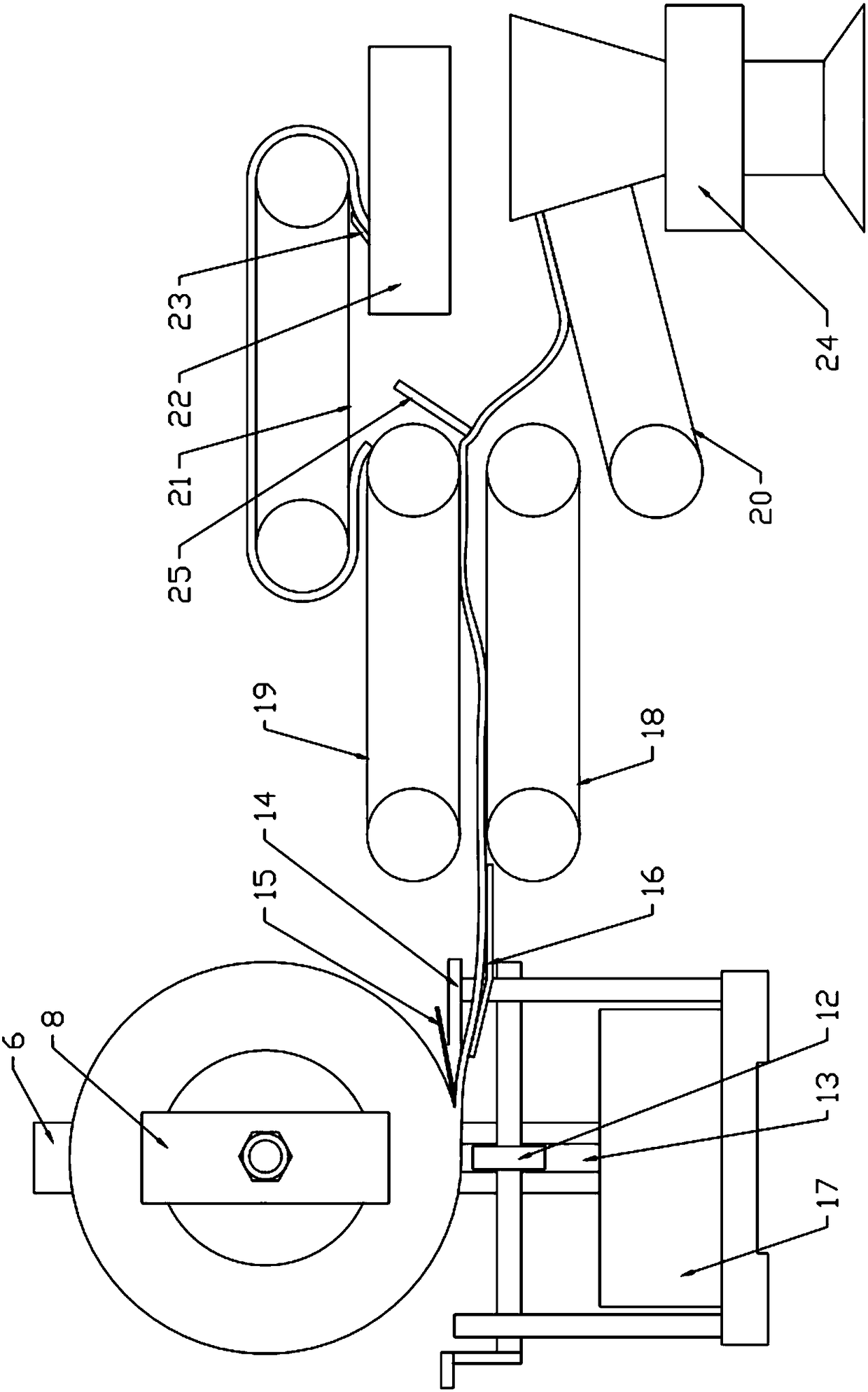

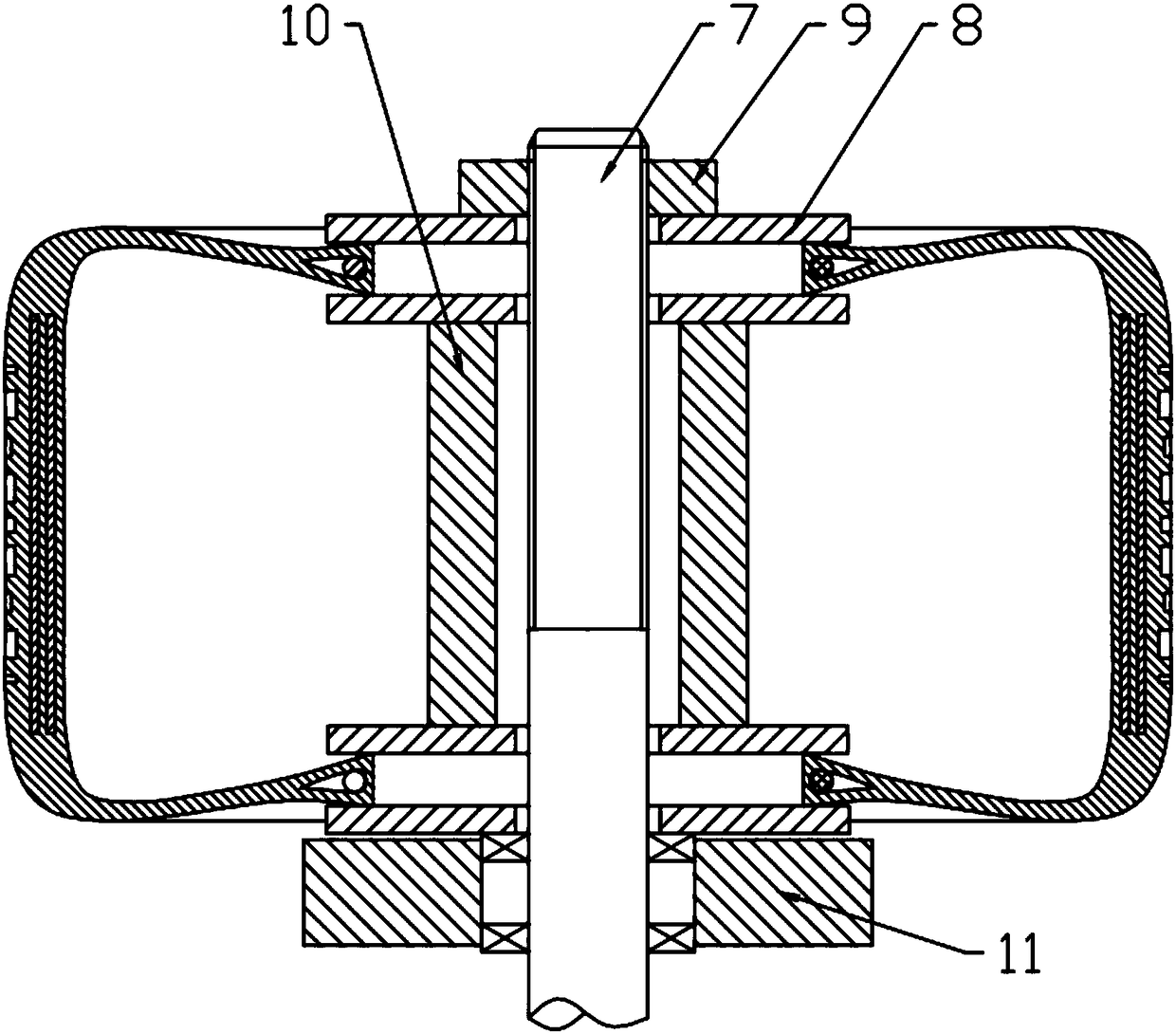

[0017] The reference signs in the drawings of the description include: bead 1, sidewall 2, carcass cord layer 3, steel belt layer 4, tread 5, frame 6, threaded rod 7, briquetting block 8, nut 9, Support cylinder 10, sliding seat 11, gear 12, rack 13, tool holder 14, blade 15, guide plate 16, receiving frame 17, first conveyor belt 18, second conveyor belt 19, third conveyor belt 20, fourth conveyor belt 21 , Collection frame 22, scraper 23, crushing device 24, saw disc 25.

[0018] The embodiment of the production system for multi-stage crushing processing of regenerated rubber is basically as attached figure 2 Shown: includes a layer stripping device, a magnetic separation device, a third conveyor belt 20 and a crushing device 24, the layer stripping device includes a frame 6, a clamping mechanism for clamping the bead 1 and a motor for driving the clamping mechanism t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com