Method and device for preparing hydrochloric acid and purifying quartz sand

A technology of quartz sand and hydrochloric acid, applied in the fields of environmental protection and energy saving, can solve problems such as increasing the cost of production enterprises, and achieve the effect of low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

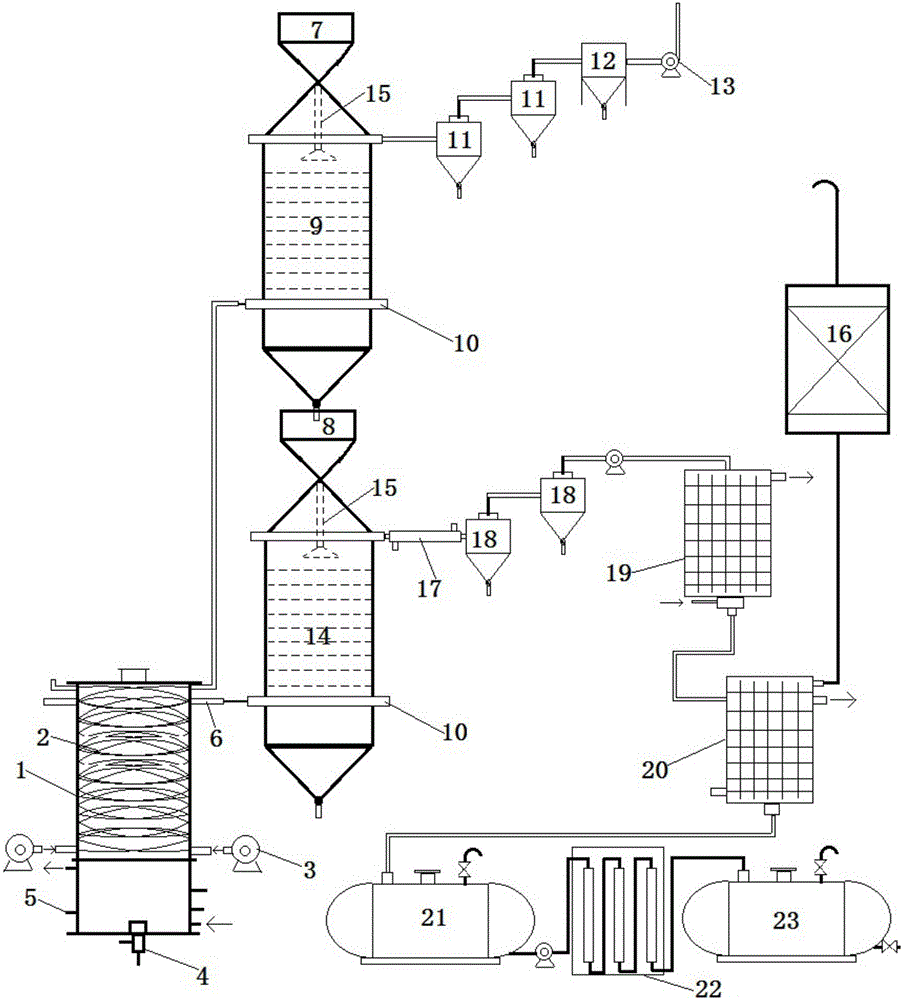

[0025] The structure of the device for preparing hydrochloric acid and purifying quartz sand provided by the present invention is as follows: figure 1 As shown, it includes hydrogen chloride gas synthesis and cooling system, quartz sand drying system, quartz sand high temperature chlorination purification system, hydrochloric acid preparation and purification system.

[0026] The hydrogen chloride gas synthesis and cooling system at least includes a synthesis furnace 1, the lower part of the furnace wall of the synthesis furnace 1 is provided with a water cooling device, and the upper part of the furnace wall is provided with a gas cooling device. The cooling air pipe 2, the inlet end of the cooling air pipe 2 is connected with the blower 3, and the outlet end of the cooling air pipe 2 leads to the quartz sand drying system. The bottom end of the synthesis furnace is provided with a chlorine and hydrogen inlet 4, an ignition device 5 is arranged in the synthesis furnace, and a...

Embodiment 1

[0031] Example 1, taking the quartz sand produced by a certain quartz sand company in Huanggang City with a particle size of 30 to 120 mesh and a water content of 5% as an example, the SiO 2 %: 99.6%, Fe 2 o 3 :0.015%.

[0032] 1. First put the quartz sand to be dried in the quartz sand silo to be dried, first turn on the induced draft fan of the drying system; then turn on the induced draft fan of the hydrogen chloride tail gas treatment system to make the hydrogen chloride falling film absorption system operate normally, then turn on the chlorination system The fan of the dust collector and the cooling water valve of the cooler in front of the dust collector are used to make them operate normally; then respectively open the valves of chlorine gas and hydrogen gas and the automatic ignition device to make them run normally, and adjust the flow of cooling water and cooling air To adjust the gas temperature of the hydrogen chloride at the outlet of the synthesis furnace betwe...

Embodiment 2

[0035] Embodiment 2, taking the quartz sand produced by a certain quartz sand company in Heyuan City as an example with a particle size of 30 to 120 mesh and a water content of 5%, SiO in the quartz sand 2 %: 99.3%, Fe 2 o 3 :0.015%

[0036] 1. First put the quartz sand to be dried in the quartz sand silo to be dried, first turn on the induced draft fan of the drying system; then turn on the induced draft fan of the hydrogen chloride tail gas treatment system to make the hydrogen chloride falling film absorption system operate normally, then turn on the chlorination system The fan of the dust collector and the cooling water valve of the cooler in front of the dust collector are used to make them operate normally; then respectively open the valves of chlorine gas and hydrogen gas and the automatic ignition device to make them run normally, and adjust the flow of cooling water and cooling air To adjust the gas temperature of the hydrogen chloride at the outlet of the synthesis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com