Filtering and washing device for KNO3

A washing device and potassium nitrate technology, which is applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problem of being unable to drain the residual liquid at the bottom of the box-shaped silo, and manually shoveling out crude potassium nitrate, which is time-consuming and laborious Low efficiency and other problems, to achieve the effect of compact structure, simple structure, time-saving and labor-saving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present application is not limited by the following examples, and specific implementation manners can be determined according to the technical solutions of the present application and actual conditions.

[0013] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 The layout method is described, such as: the positional relationship of top, bottom, left, right, etc. is based on the attached figure 1 determined by the layout direction.

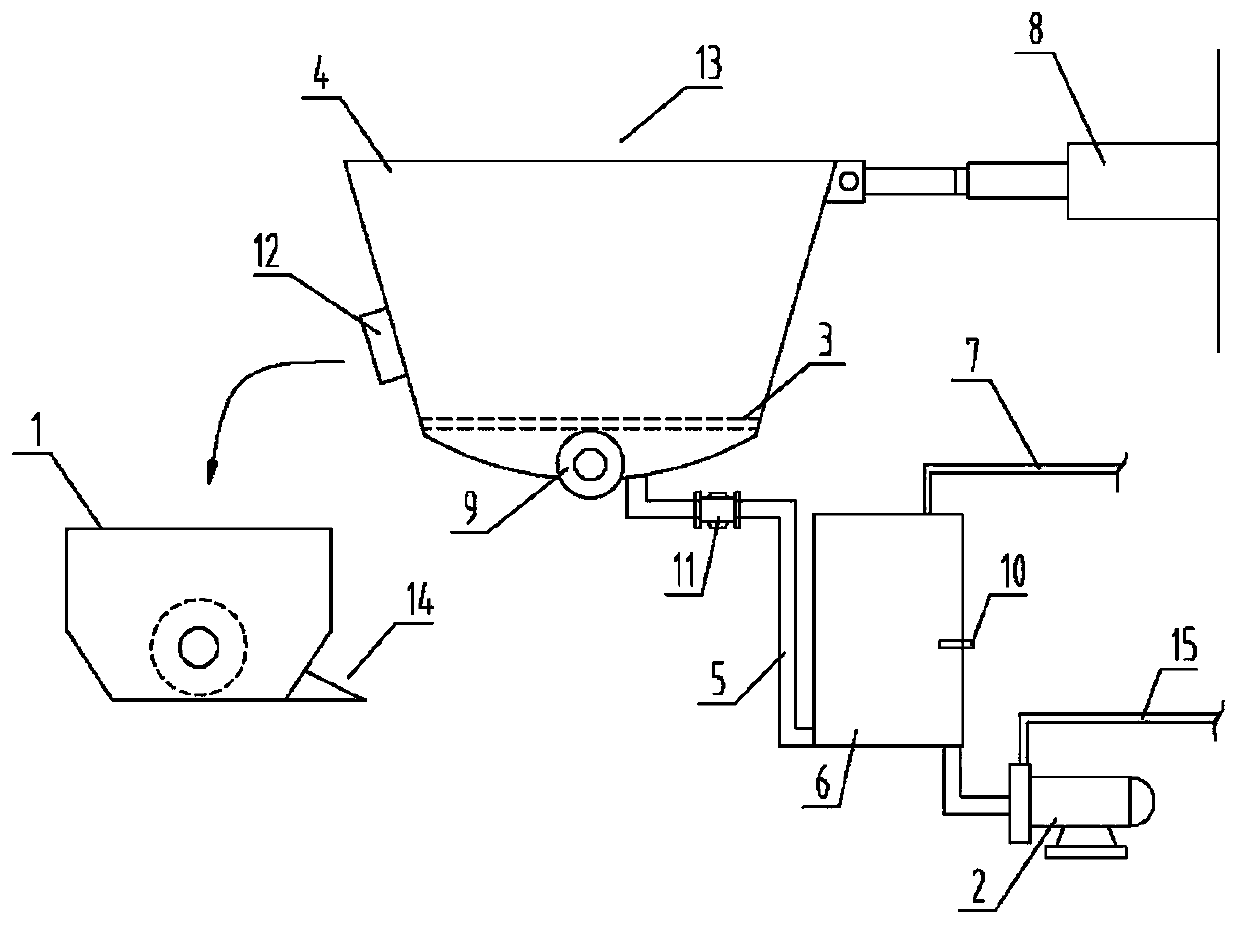

[0014] The present invention will be further described below in conjunction with embodiment and accompanying drawing, embodiment: as attached figure 1 As shown, the filtering and washing device for potassium nitrate includes a frame, a tipping bucket mechanism, a screw conveyor 1, a suction filter pump 2, and a control host. The tipping bucket mechanism and the screw conveyor 1 are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com