Green preparation method of lithium sulfide

A lithium sulfide, green technology, applied in the direction of alkali metal sulfide/polysulfide, electrochemical generator, positive electrode, etc., can solve the problem of increasing the reaction process and subsequent processing steps, increasing the research burden in the field of lithium sulfide, and complicating the preparation process and other problems, to achieve the effect of facilitating purification, realizing large-scale continuous preparation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

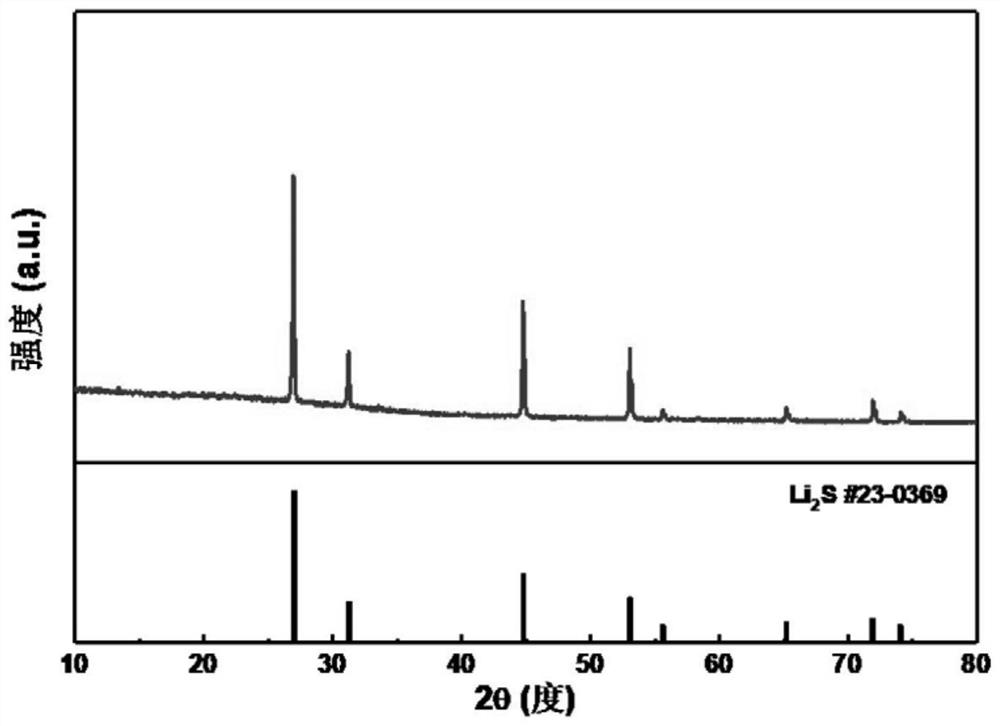

[0027] In a glove box filled with argon atmosphere, lithium amide and elemental sublimed sulfur were weighed according to the molar ratio of 2:1, ground evenly by hand, then transferred to a heating tube, vacuumed, and 30 bar hydrogen gas was introduced. Heat to 300°C at a heating rate of 2°C / min, keep it warm for 5 hours, after the reaction is completed, the temperature of the reactor drops to room temperature, vacuumize, transfer the reactor to a glove box with argon atmosphere, open the reactor, and take out the powder sample That is the required lithium sulfide powder. figure 1 It is the X-ray diffraction pattern corresponding to the product, and the obtained product is lithium sulfide.

Embodiment 2

[0029] In a glove box filled with argon atmosphere, weigh imide lithium and elemental sublimed sulfur according to the molar ratio of 2:1, grind them evenly by hand, then transfer them to a heating tube, vacuumize, and inject 50bar hydrogen. Heat up to 500°C at a heating rate of 5°C / min, keep warm for 1h, after the reaction is completed, the reactor temperature drops to room temperature, vacuumize, transfer the reactor to an argon atmosphere glove box, open the reactor, and take out the powder sample That is the required lithium sulfide powder.

Embodiment 3

[0031] In a glove box filled with a helium atmosphere, lithium amide and elemental sublimed sulfur were weighed according to a molar ratio of 2:1, ground evenly by hand, then transferred to a heating tube, vacuumed, and 10 bar hydrogen gas was introduced. Heat up to 200°C at a heating rate of 5°C / min, keep it warm for 20 hours, after the reaction ends, the reactor temperature drops to room temperature, vacuumize, transfer the reactor to a glove box with a helium atmosphere, open the reactor, and take out the powder sample That is the required lithium sulfide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com