Preparation method and application of a camphor molecularly imprinted polymer and its monolithic column and packed chromatographic column

A packed chromatographic column and molecular imprinting technology is applied in the field of preparation of camphor molecularly imprinted polymer and its monolithic column and packed chromatographic column, and achieves the effects of good molecular recognition performance, simple and easy preparation process, and overcoming serious impurity interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

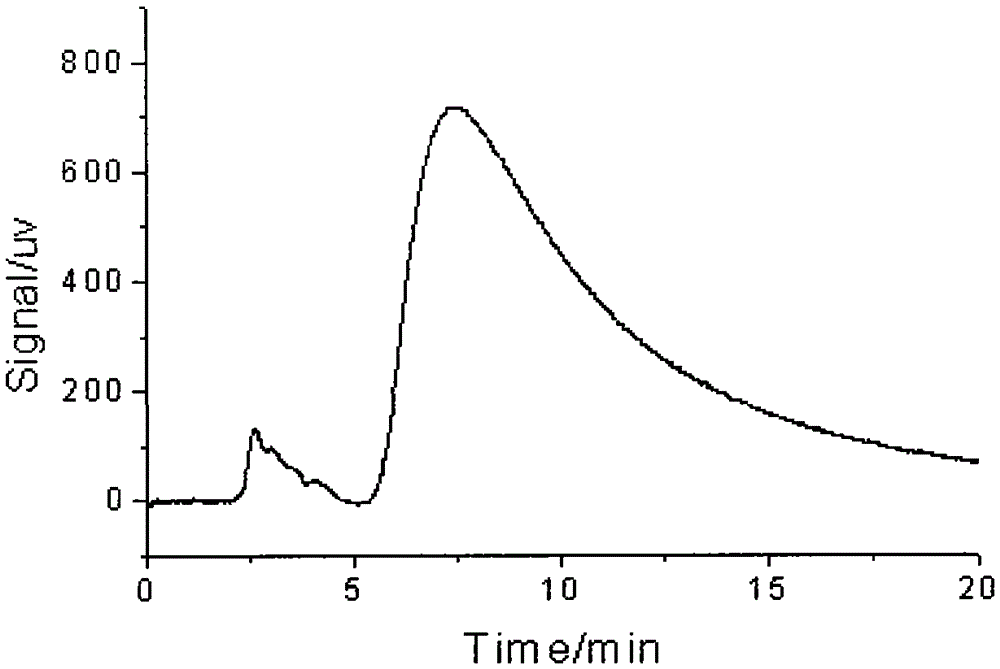

Embodiment 1

[0039] Firstly, 0.9 mmol of template molecule camphor was dissolved in 8 mL of porogen methanol, and 1.8 mmol of functional monomer methacrylic acid, 8 mmol of crosslinking agent ethylene glycol dimethacrylate, and 30 mg of initiator azobisisobutyronitrile were added and mixed. ; Ultrasonic treatment in an ice-water bath for 15 minutes, then pass nitrogen gas for 15 minutes, inject this solution into a stainless steel chromatographic column (150 mm × 4.6 mmi.d) that has sealed the lower nozzle, seal the upper nozzle, and put it into an oven at 50 ° C for reaction After 24 hours, thermal initiation resulted in a molecularly imprinted monolithic column. Connect the column to the liquid chromatography pump and use methanol:water (95:5, v / v) to remove the template molecules to obtain a camphor molecularly imprinted monolithic column (MIP1).

Embodiment 2

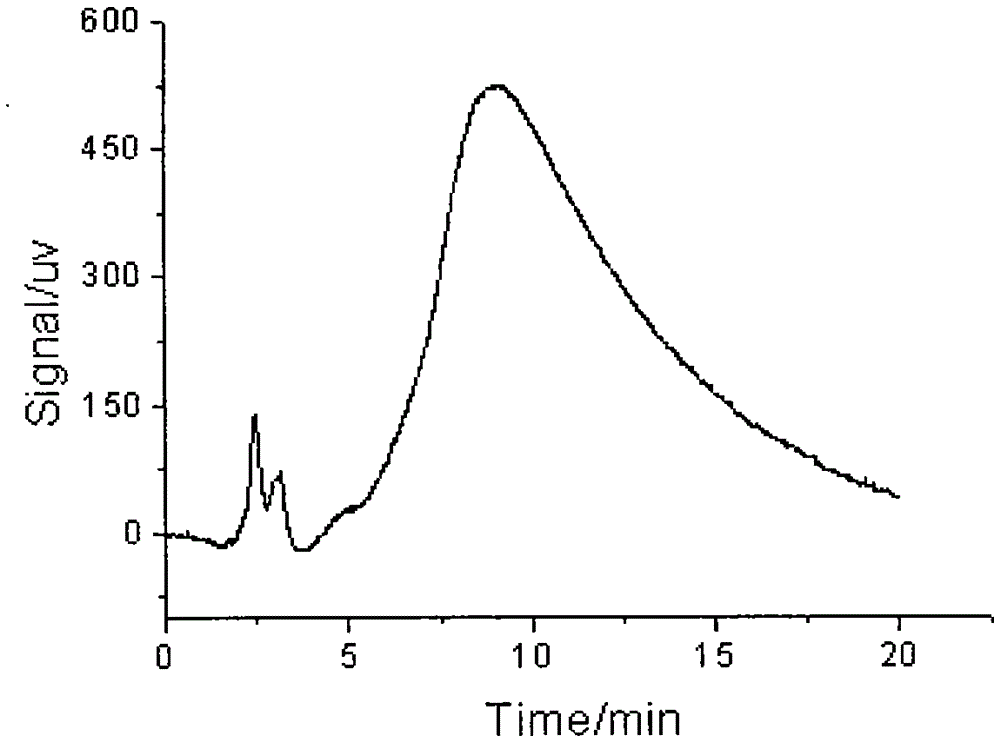

[0041]Firstly, 0.9 mmol of template molecule camphor was dissolved in 8 mL of porogen methanol, and 3.6 mmol of functional monomer methacrylic acid, 8 mmol of cross-linking agent ethylene glycol dimethacrylate, and 30 mg of initiator azobisisobutyronitrile were added and mixed. ; Ultrasonic treatment in an ice-water bath for 15 minutes, and then pass nitrogen gas for 10 minutes, inject this solution into a stainless steel chromatographic column (150 mm × 4.6 mmi.d) that has sealed the lower nozzle, seal the upper nozzle, and put it into a 55 ° C oven for reaction After 24 hours, thermal initiation resulted in a molecularly imprinted monolithic column. Connect the column to the liquid chromatographic pump and use methanol:water (95:5, v / v) to remove the template molecules to obtain a camphor molecularly imprinted monolithic column (MIP2).

Embodiment 3

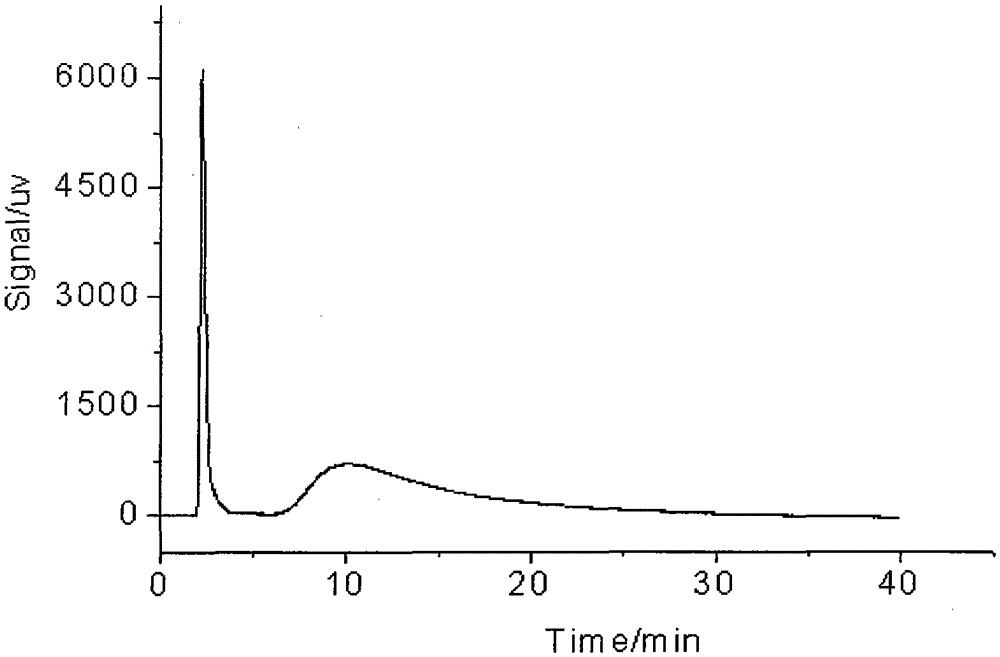

[0043] Firstly, 0.9 mmol of template molecule camphor was dissolved in 8 mL of porogen methanol, and 5.4 mmol of functional monomer methacrylic acid, 8 mmol of cross-linking agent ethylene glycol dimethacrylate, and 30 mg of initiator azobisisobutyronitrile were added and mixed. ; Ultrasonic treatment in an ice-water bath for 20 minutes, then pass nitrogen gas for 10 minutes, inject this solution into a stainless steel chromatographic column (150 mm × 4.6 mmi.d) that has sealed the lower nozzle, seal the upper nozzle, and put it into a 55 ° C oven for reaction For 12 hours, thermal initiation resulted in a molecularly imprinted monolithic column. Connect the column to the liquid chromatography pump and use methanol: water (95:5, v / v) to remove the template molecules to obtain a camphor molecularly imprinted monolithic column (MIP3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com