Repairing method of body cave

A body and cavitation technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of long cycle, high price, unfavorable locomotive maintenance operations, etc., and achieve the effect of improving mechanical performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

test example 1

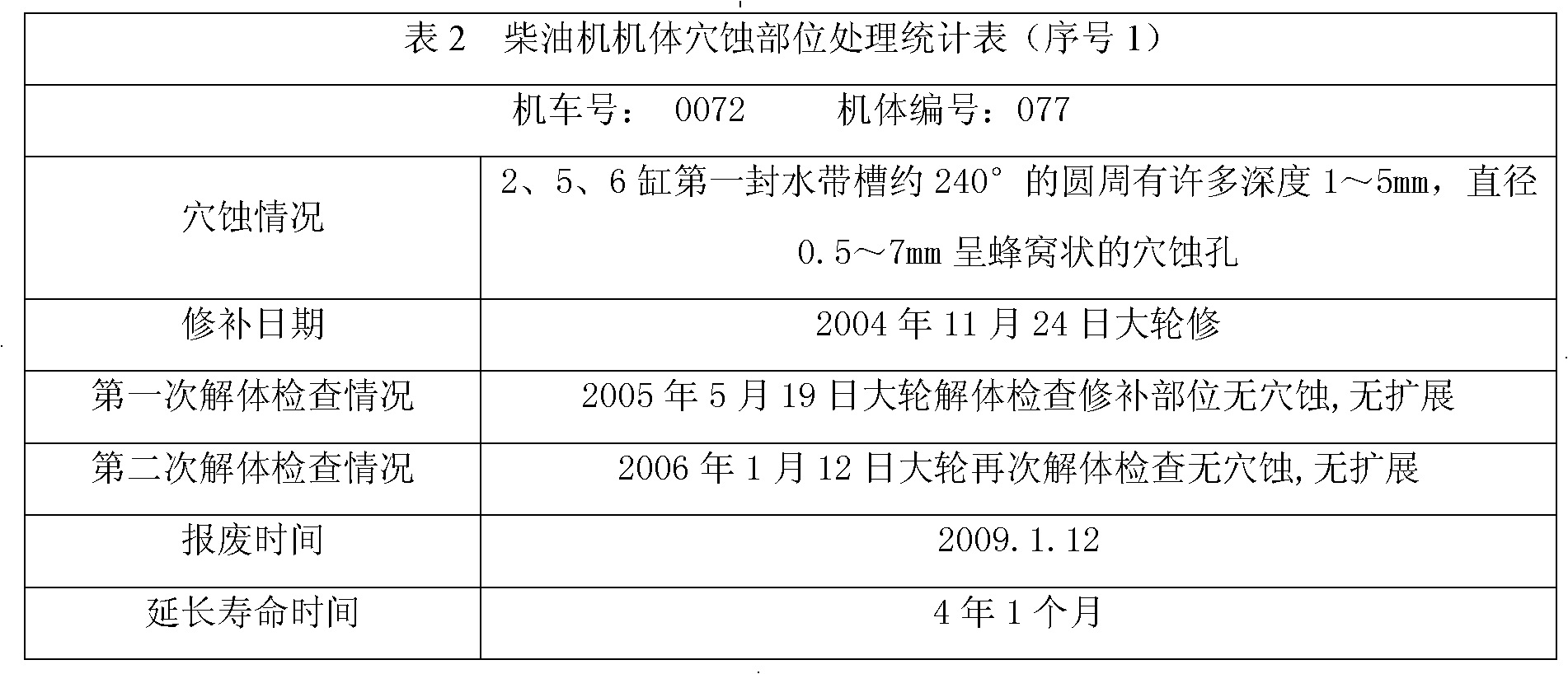

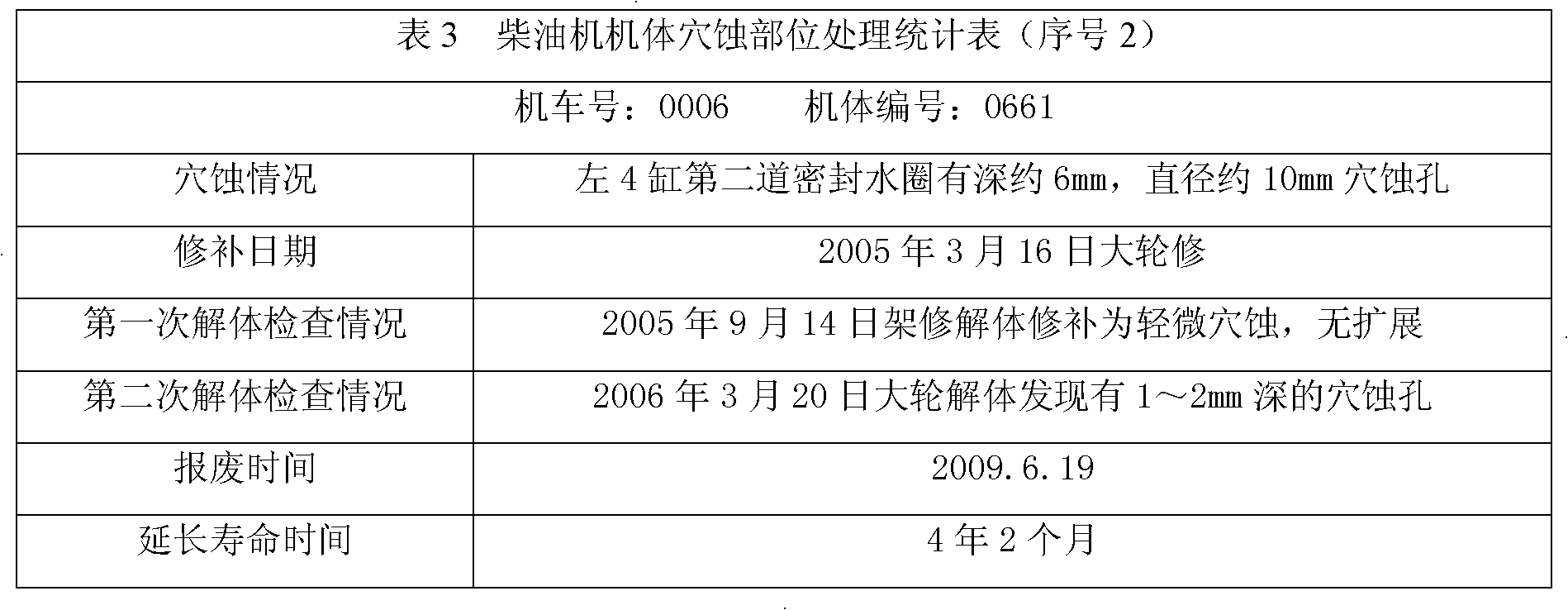

[0021] Test case 1 AB glue

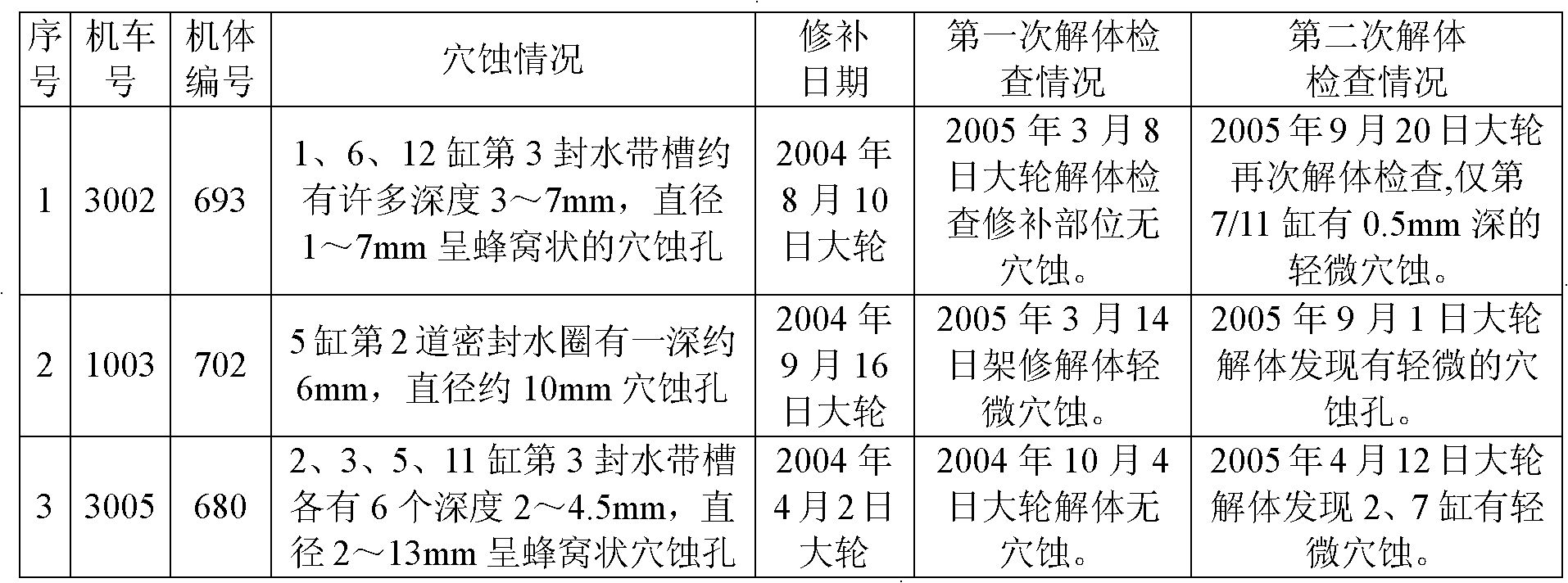

[0022] In February 2004, the method of AB glue and iron powder mixed repair was tried on 3 airframes with cavitation, and the method was applied to the cavitation part after polishing, and it was used after curing at room temperature for 12 hours, but in a large repair period (6 months) After the disintegration of the body, it was found that the effect was not satisfactory: after repair, the cavitation parts were all detached, and the cavitation parts continued to spread and produce new cavitation.

[0023] Analysis of the main reason is that the temperature resistance of the AB glue repair agent is only 80°C, the temperature of the body can be as high as 90°C during the operation, and the AB glue cannot meet the temperature requirements; in addition, it is not easy to determine the mixing ratio of AB glue and iron powder when the repair agent is mixed. The adhesion of the mixed repair agent is not enough and easy to fall off, which will directly a...

experiment example 2

[0024] Experimental case 2 SY-111 iron repair agent

[0025] 1. Manufacturer: Yantai Jinyi Chemical Co., Ltd.;

[0026] Product properties and uses: gray iron color, clay-like. It is suitable for the repair of defects such as air holes, sand holes, and cracks in iron castings of various materials, as well as the repair and regeneration of worn and damaged parts of various mechanical equipment.

[0027] 2. Operation process

[0028] 1) Surface treatment: The surface to be repaired must be free of oil, water and other impurities. If possible, it can be roughened with an angle grinding wheel, sandblasting gun, etc., and then cleaned with acetone or alcohol and dried.

[0029] 2) Mixing: Mix A and B components strictly according to the specified ratio, and stir well until the colors are completely consistent.

[0030] 3) Coating: Use a scraper or a rubber knife to apply a small amount of the repairing agent on the surface to be repaired, and press repeatedly to fully infiltrate...

test example 3

[0034] Test case 3 Fast steel glue stick (FastStell)

[0035] 1. Product manufacturer and performance:

[0036] Brand: PSI / Push

[0037] Original model: FastStell

[0038] Where to buy: USA

[0039] This product is a steel-reinforced repairing agent, which can fill and bond leaks, cracks, blisters, defects, fractures, damages, etc. on steel, iron, aluminum and other metal containers, pipes and parts. . In addition, it can quickly make and copy parts, models, and templates, repair peeled threads, and be used as nuts and bolts for fastening, sealing, and other various forms of installation and fixing.

[0040]Product trial method: Before use, the floating rust, dust and oil stains around the area to be repaired must be cleaned up. Take out the colloid in the plastic tube, cut off the required amount, and knead the two different colors of the colloid inner core and outer skin into one color by hand (about 1 to 2 minutes) until it is uniform. Press it firmly into the patch a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com