Harmless and resource utilization method of steel industry chromium-containing wastewater

A harmless technology for the iron and steel industry, applied in chemical instruments and methods, metallurgical wastewater treatment, process efficiency improvement, etc. Completely harmless, complete treatment effect, and the effect of reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

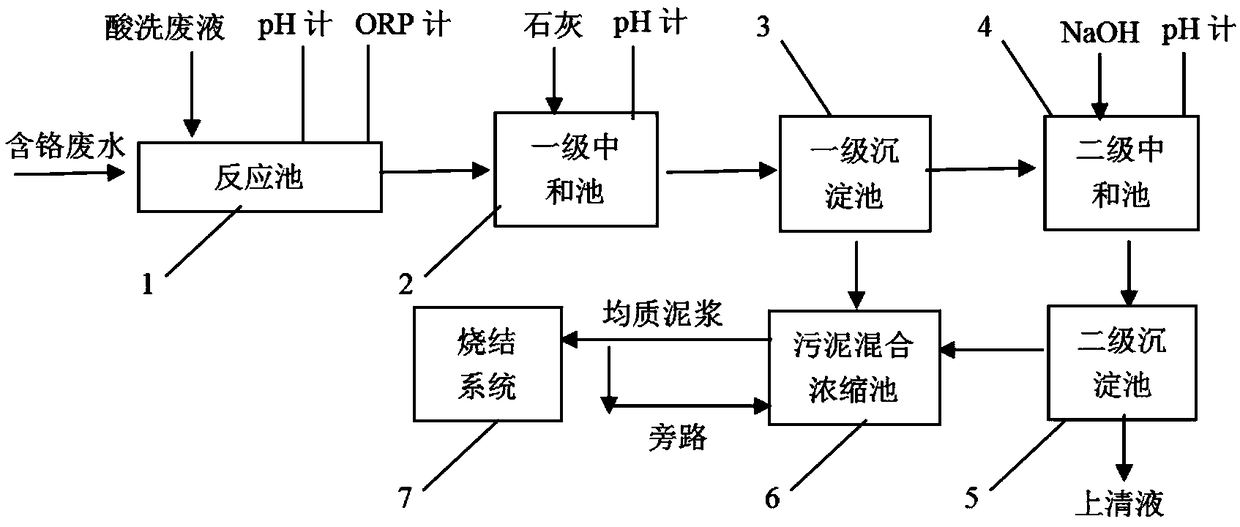

[0030] like figure 1 As shown, the process system adopted in this embodiment mainly includes a reaction tank 1, a primary neutralization tank 2, a primary sedimentation tank 3, a secondary neutralization tank 4, a secondary sedimentation tank 5, a sludge mixing and concentration tank 6, Sintering system 7 and pipelines for transporting sludge, etc. Among them, the reaction tank is equipped with a pH meter and an ORP meter; the primary neutralization tank and the secondary neutralization tank are equipped with a pH meter; pool.

[0031] After the above-mentioned system is connected with pipelines and pumps, the harmless and resourceful utilization of chromium-containing wastewater is carried out according to the following steps:

[0032] 1) Add steel rolling system pickling waste liquid into the reaction pool, the H in the pickling waste liquid + Concentration is 1wt%, Fe 2+ The concentration is 1g / L, and the dosage is equal to the amount of Fe in the pickling waste liquid ...

Embodiment 2

[0039] This embodiment adopts the same process system as Embodiment 1, and carries out harmless and resourceful utilization of chromium-containing wastewater according to the following steps:

[0040] 1) Add steel rolling system pickling waste liquid into the reaction pool, in the pickling waste liquid, H + Concentration is 2.5wt%, Fe 2+ The concentration is 3g / L, and the dosage is based on the amount of Fe in the pickling waste liquid 2+ and Cr in chromium-containing wastewater 6+ The molar ratio is 4 as the criterion, the pH value of the control reaction is 2, the oxidation-reduction potential of the control reaction pool is 330mv, and the reaction time is 30min;

[0041] 2) After step 1), the waste water flows to the first-level neutralization tank by itself, and a lime slurry with a CaO concentration of 25% is added to the neutralization tank to adjust the pH value of the mixed solution to 8.5, and the adjusted mixed solution flows to the first-level precipitation Separ...

Embodiment 3

[0047] This embodiment adopts the same process system as Embodiment 1, and carries out harmless and resourceful utilization of chromium-containing wastewater according to the following steps:

[0048] 1) Add steel rolling system pickling waste liquid into the reaction pool, in the pickling waste liquid, H + Concentration is 5wt%, Fe 2+ The concentration is 5g / L, and the dosage is equal to the amount of Fe in the pickling waste liquid 2+ and Cr in chromium-containing wastewater 6+ The molar ratio is 5 as the criterion, the control reaction pH is 1, the oxidation-reduction potential of the control reaction pool is 350mv, and the reaction time is 30min;

[0049] 2) After step 1), the wastewater flows to the first-level neutralization tank by itself, and the lime slurry with a CaO concentration of 30% is added to the neutralization tank to adjust the pH value of the mixed solution to 9, and the adjusted mixed solution flows to the first-level sedimentation Separation of mud and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com