Production apparatus and production method for methyl nitrite

A technology of methyl nitrite and production equipment, which is applied in the direction of nitrite preparation, organic chemistry, etc., can solve the problem of inability to ensure continuous and stable operation of the system, high requirements for the comprehensive quality and technical level of operators, and unstable product quality, etc. problem, to achieve the effect of high labor intensity, high risk factor and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

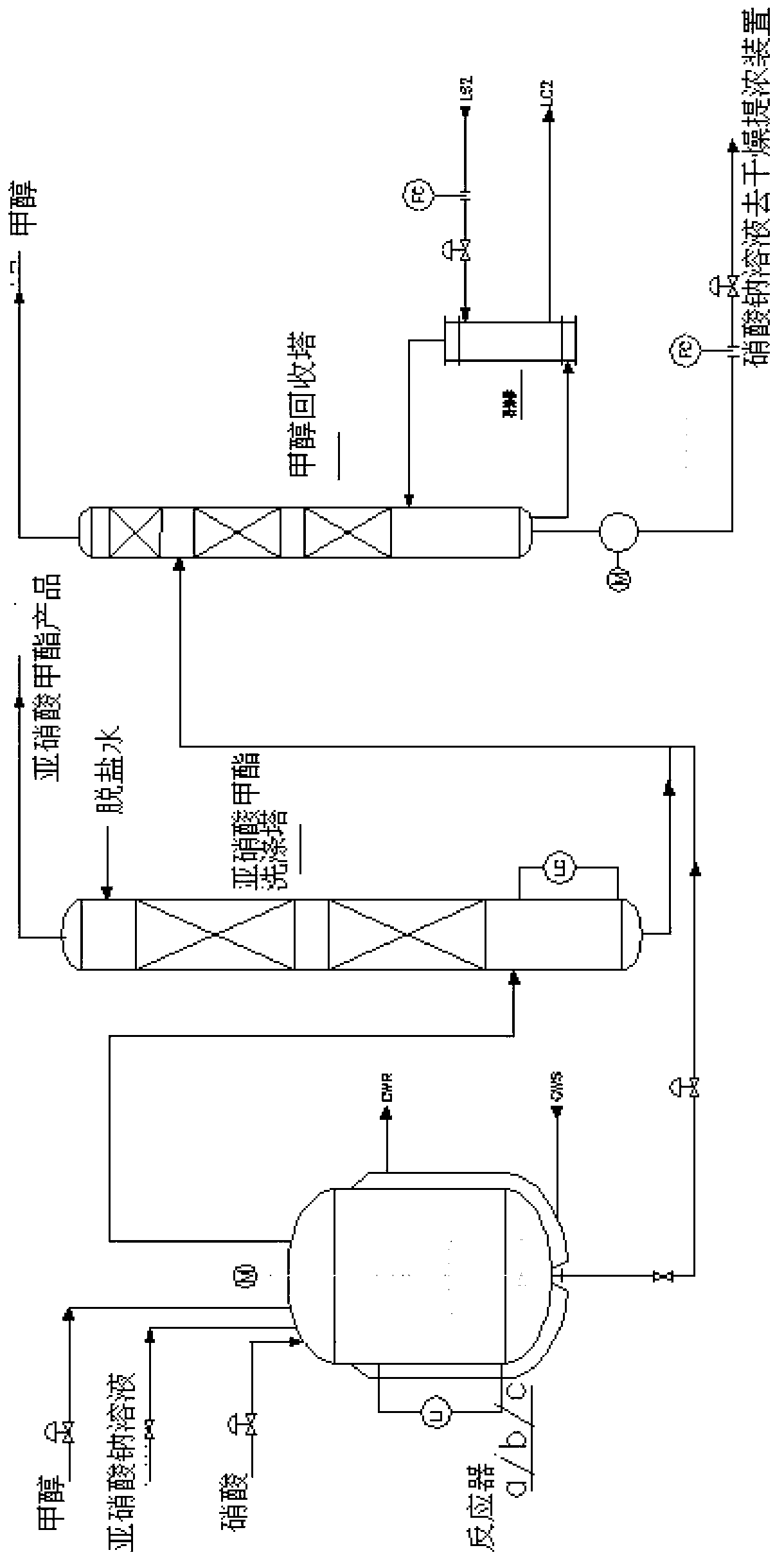

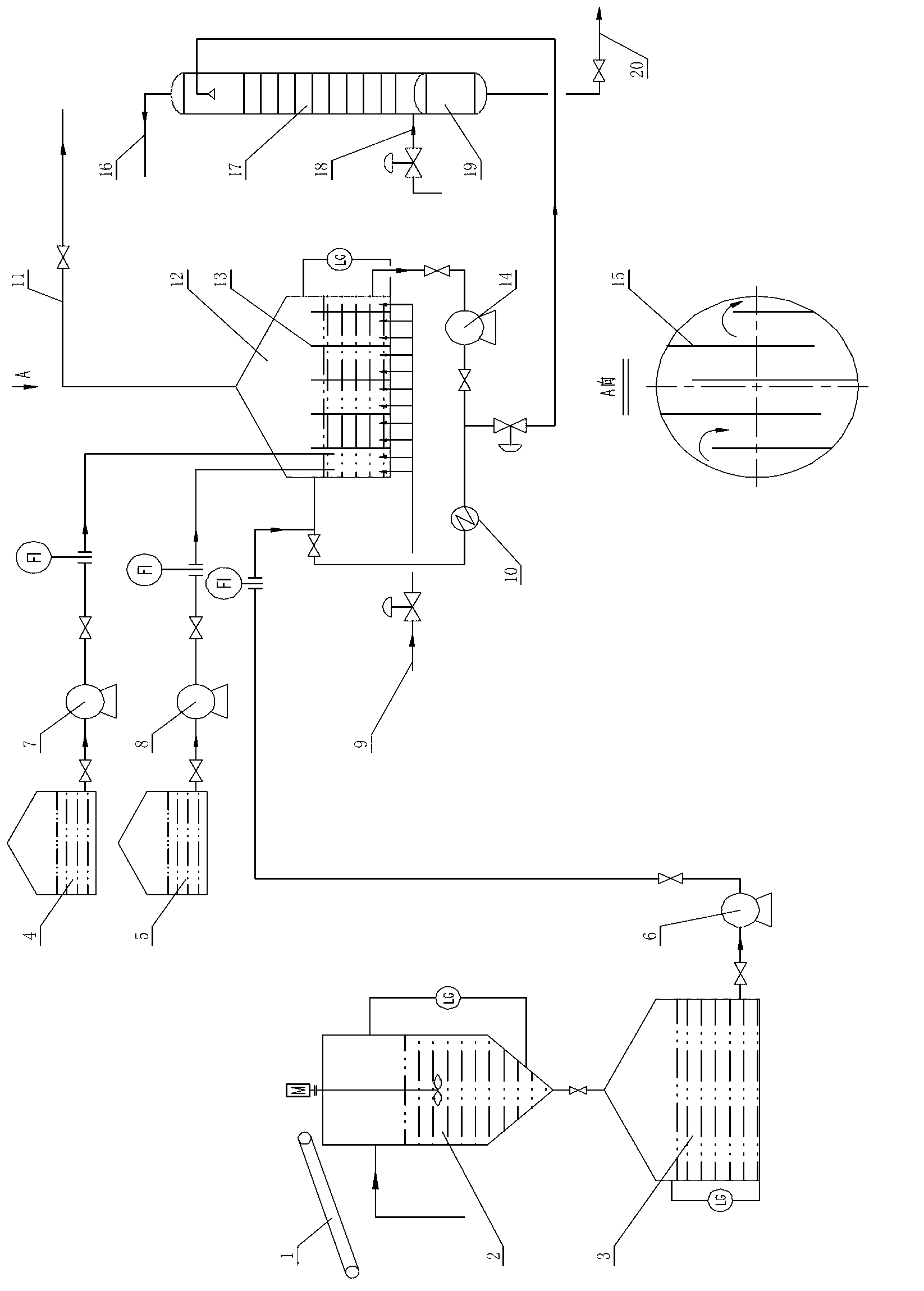

[0048]The device invented by the method consists of 1. belt conveying device, 2. dissolving stirring tank, 3. the first storage tank, 4. the second storage tank, 5. the third storage tank, 6. the first delivery pump, 7. the second Delivery pump, 8. The third delivery pump, 9. Nitrogen delivery pipe, 10. Circulating water cooler, 11. Methyl nitrite, 12. Reactor, 13. Baffle plate, 14. The fourth delivery pump, 15. Baffle plate (with baffle plate 13, is top view), 16. gas outlet, 17. rectification tower, 18. low-pressure steam inlet, 19. reboiler, 20. pipelines and equipment such as sodium nitrate solution outlet.

[0049] The belt conveyor 1 is connected to the dissolving stirring tank 2, and the bottom of the dissolving stirring tank 2 is connected to the first storage tank 3, the first storage tank 3 is connected to the reactor 12 through the first delivery pump 6, the second storage tank 4 and the third storage tank The tank 5 is connected to the reactor 12 through the second...

Embodiment 2

[0053] The method utilizing device of the present invention to produce methyl nitrite is:

[0054] a) Before the reactor 12 introduces raw materials, the circulating water cooler 10 introduces circulating water at 32°C to establish a circulating water system; the pressure of the reboiler 19 is set to 0.6MPa. The goodness of oil level, power supply and standby machine, etc., sodium nitrite solution, methanol and nitric acid solution are all ready, and the liquid level of each storage tank is not lower than 60%.

[0055] Implementation process:

[0056] b) The belt conveyor 1 transports the sodium nitrite solid to the top of the dissolving and stirring tank 2, and mixes and stirs the sodium nitrite solution with a concentration of 40% through the motor-driven agitator, and then enters the first storage tank 3, and the sodium nitrite solution passes through The first delivery pump 6 is delivered to the reactor 12. At the same time, the fresh methanol in the second storage tank 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com