Process for producing dimethyl carbonate from industrial synthetic gas

A technology of dimethyl carbonate and synthesis gas, which is used in the preparation of carbonate/haloformate, the reaction preparation of carbon monoxide or formate, and the chemical industry, which can solve the problems of ineffective recovery of heat energy and energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

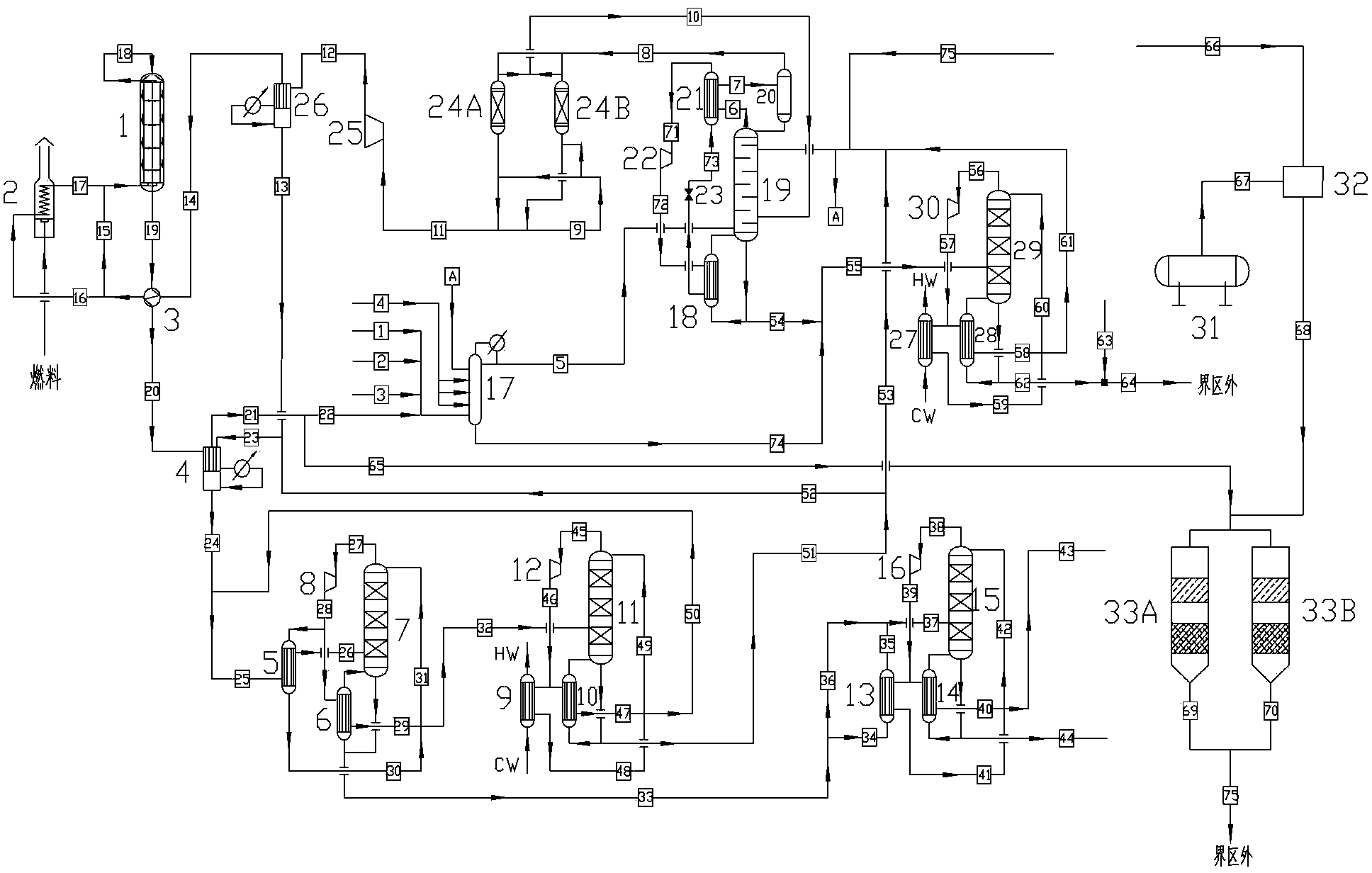

[0141] In this example, refer to the attached figure 1 The apparatus and procedures shown set up the various reaction components.

[0142] Industrial-grade CO (98V%), which is the reaction raw material of carbonylation reactor 1, and nitrogen, which is an inert gas source, are used together as a pre-esterification tower 17 (inner diameter 160mm, height 1500mm, theoretical plate number 20, and the plate structure is sieve plate type plate reaction distillation tower) reaction hot dilution gas and cycle gas (composition: CO: 10.7v%, CO 2 :2.4v%, MN: 9.6v%, N 2 : 63.9v%, Methanol: 2.6v%, DMC: 0.8v%, NO: 10v%) and NO from outside the boundary area are mixed and then enter the pre-esterification tower 17 (the 16th tray is fed and fed), and the separated Oxygen entering the pre-esterification tower 17 from the three routes (feeding at the 2nd, 6th and 10th trays) and the methanol raw material fed into the first tray at the top of the tower are countercurrently contacted on the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com