Water-cooling heat dissipation display module

A display module, water-cooled heat dissipation technology, applied in the direction of cooling/ventilation/heating transformation, photovoltaic modules, support structures of photovoltaic modules, etc., can solve the problem of affecting the service life of LEDs, luminous efficiency and stability, and cannot guarantee the backlight and display Stable operation of the panel, low efficiency of air transmission and heat dissipation, etc., to achieve the effect of improving charging efficiency, increasing the area exposed to sunlight, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

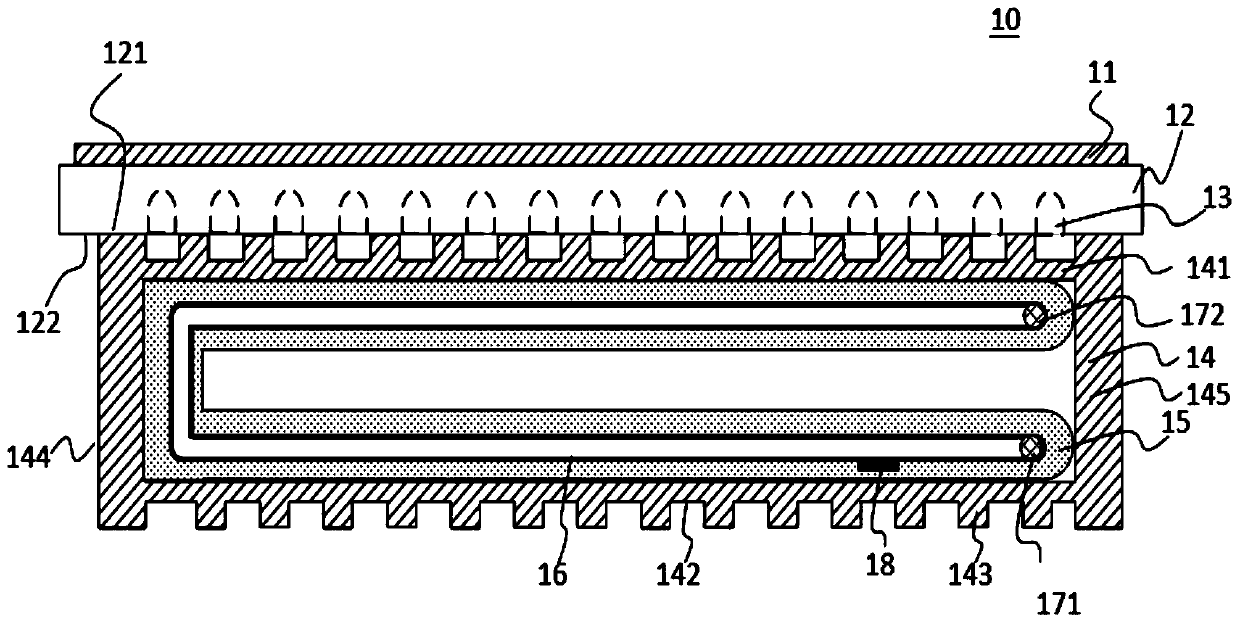

[0034] Please refer to figure 1 with figure 2 , figure 1 A top view of a water-cooled and heat-dissipating display module provided for the implementation of the present invention, figure 2 along figure 1 In the schematic diagram of the AA' section in the middle, the water-cooled and heat-dissipating display module 10 includes a display panel 11 and a lamp board 12. The top surface 121 of the lamp board 12 close to the display panel 11 is provided with a plurality of LED lamp beads 13, and the lamp board 12 is far away from the display panel. The bottom 122 on one side of the panel 11 is provided with a cooling chamber 14 . A cooling water belt 15 is arranged inside the heat dissipation cavity 14 , and the cooling water belt 15 is arranged along the inner surface of the heat dissipation cavity 14 . As shown in the figure, the shape of the lamp panel 12 is a straight plate, and the heat dissipation cavity 14 includes a top surface 141 near the bottom 122 of the lamp panel....

Embodiment 2

[0047] Image 6 A schematic diagram of a water-cooled and heat-dissipating display module provided in Embodiment 2 of the present invention. The water-cooling and heat-dissipating display module 20 includes a display panel 21 and a lamp panel 22. The top surface 221 of the lamp panel 22 near the display panel 21 is provided with a plurality of The LED lamp bead 23 and the bottom 222 of the lamp board 22 away from the display panel 21 are provided with a cooling cavity 24 . A cooling water belt 25 is arranged inside the heat dissipation cavity 24 , and the cooling water belt 25 is arranged along the inner surface of the heat dissipation cavity 24 . As shown in the figure, the cooling water belt 25 is a U-shaped structure, and the cooling water belt 25 of the U-shaped structure is in contact with the top surface 241, the bottom surface 242, and a side surface 244 between the top surface 241 and the bottom surface 242 of the cooling cavity 24, On the other side is the opening po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com