A kind of fuel type automatic air heater

An air heater, fully automatic technology, applied to fluid heaters, burners, lighting and heating equipment, etc., can solve the problems of insensitive adjustment of hot air temperature and poor safety of fuel oil heaters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

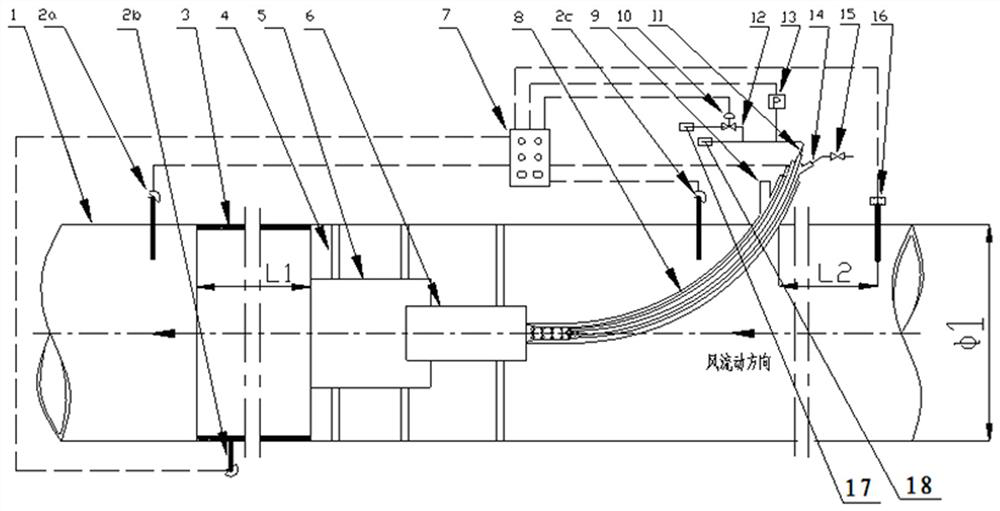

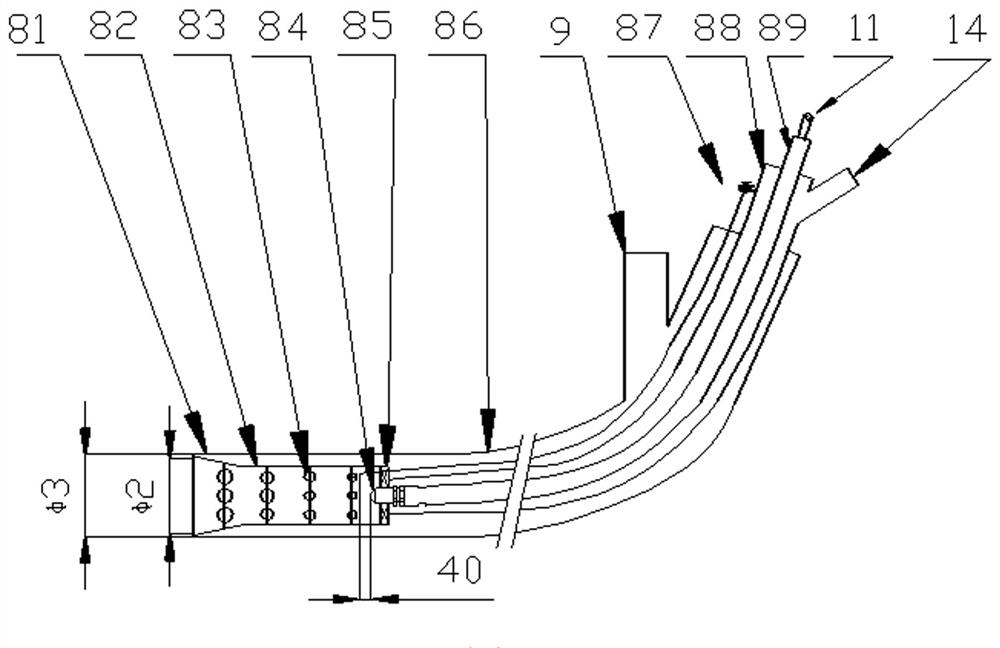

[0021] Such as figure 1 As shown, a fuel-fired fully automatic air heater in this embodiment includes a thermocouple 2a, a thermocouple 2b, a thermocouple 2c, a castable refractory layer 3, a supporting and fixed steel beam 4, a secondary combustion cylinder 5, a Stage combustion cylinder 6, control cabinet 7, oil gun assembly 8, sealed air pipe joint 9, electric control valve 10, fuel pipe joint 11, oil return branch pipe 12, pressure transmitter 13, compressed air pipe joint 14, manual stop valve 15. The flow meter 16 leads a steel pipe from the existing oil main pipe of the boiler to the vicinity of the heater by welding, and connects it with the inlet of the fuel pipe joint 11 through a metal hose by threading, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com