Method and equipment for continuously producing methyl nitrite

A technology of methyl nitrite and methanol, applied in the preparation of nitrite, organic chemistry, etc., can solve the problems of increasing the amount of wastewater generated, and achieve the effects of minimizing factory investment, minimizing wastewater discharge, and reducing the amount of wastewater generated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

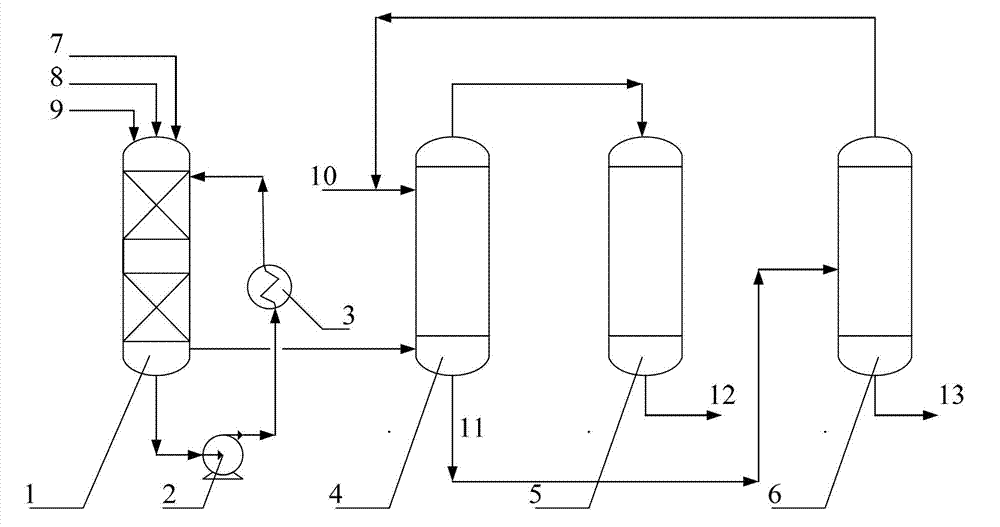

[0066] Methyl nitrite is produced by the above-mentioned process.

[0067] (1) The raw material liquid methanol 2000kg / h is pressurized to 0.7MPa (G) by the pump and sent to the top distributor of esterification reaction tower 1, 200Nm 3 / h0.5~1MPa(G) Oxygen is sent to the top distributor of esterification reaction tower 1 through the pipeline, and the amount of NO input is 78kg / h, which can be mixed with the circulating gas returned from the carbonylation system, and flows into the packing reaction zone for reaction. Both the oxidation and esterification of NO take place in the entire reactor space. By turning on the methanol circulation pump at the bottom of the esterification reaction tower 1, the 20t / h methanol solution was transported to the methanol external heat exchanger 3 for cooling, and then returned to the top of the esterification reaction tower for redistribution. The esterification reaction temperature was controlled at 85 °C and the reaction pressure was 0.65 ...

Embodiment 2

[0075] Repeat the process described in Example 1 to produce methyl nitrite. But purifying tower 4 selects toluene as purifying agent, recovery tower 6 is extraction tower, top operating pressure is 0.1MPa (G), operating temperature is 25 ℃. The bottom line 13 of the recovery tower 6 obtains 893 kg / h of esterification by-product materials such as water and nitric acid.

Embodiment 3

[0077] Repeat the process described in Example 1 to produce methyl nitrite. But the purifying agent of purification tower 4 is ethanol, the flow rate of the purifying agent is 5500kg / h (equivalent to the purifying agent per unit time: the molar ratio of the outlet reaction gas is 30:1), the operating pressure at the top of the recovery tower 6 is 0.35MPa (G), and the operating temperature is 35 °C. The bottom line 13 of the recovery tower 6 obtains 1250kg / h of by-product materials of the esterification reaction such as water and nitric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com