Method for realizing methanol/ethylene glycol co-production through coal chemical industry and green hydrogen coupling

A technology of coal chemical industry and ethylene glycol, applied in hydrogen/synthesis gas production, chemical instruments and methods, preparation of organic compounds, etc., can solve problems such as large carbon emissions, reduce carbon emissions and meet continuity requirements , the effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

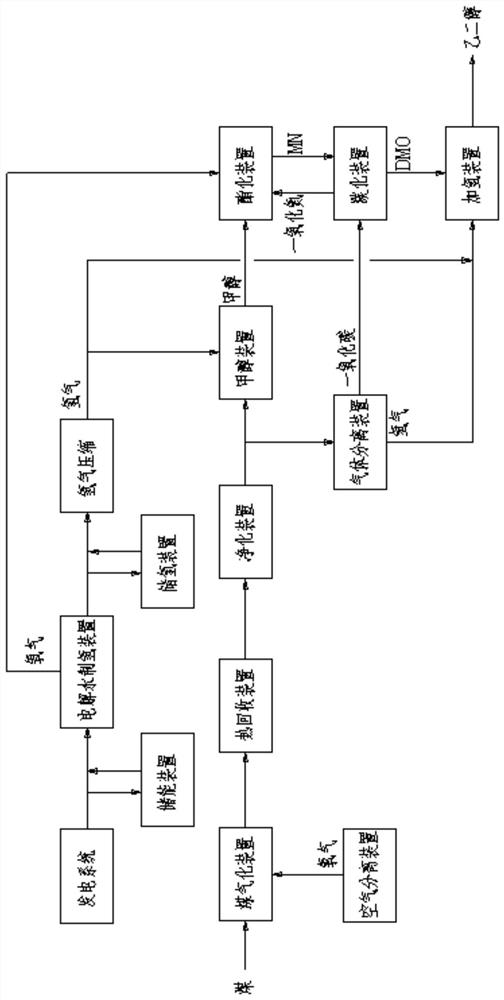

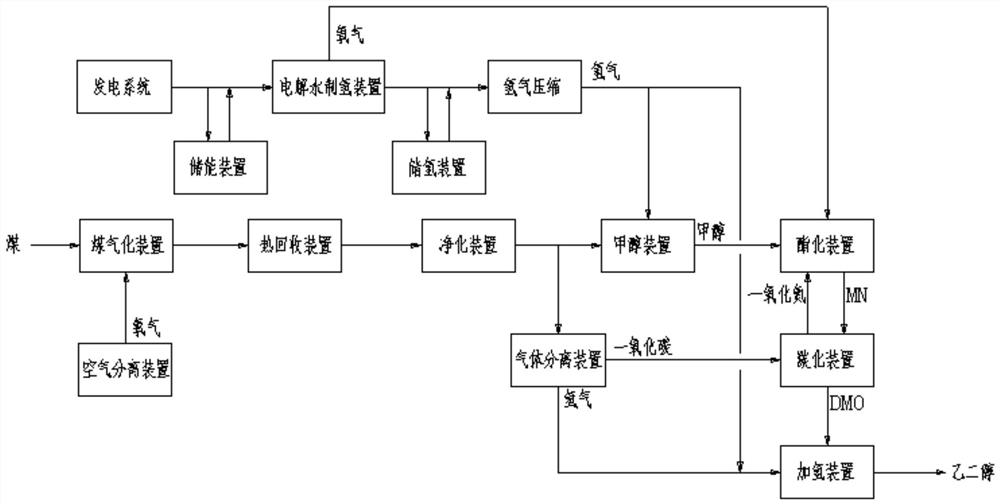

[0013] Such as figure 1 As shown, a methanol / ethylene glycol co-production device is realized through the coupling of coal chemical industry and green hydrogen, including power generation system, energy storage device, electrolysis water hydrogen production device, hydrogen storage device, hydrogen compression, coal gasification device, air separation equipment, heat recovery unit, purification unit, gas separation unit, methanol unit, esterification unit, carbonylation unit and hydrogenation unit.

[0014] The power generation system is a renewable energy power generation system. The renewable energy power generation system is one or more of hydropower generation system, wind power generation system, solar power generation system, nuclear power generation system, biomass power generation system, geothermal power generation system, tidal power generation system or ocean wave power generation system.

[0015] The electrolyzed water hydrogen production device consists of one or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com