Preparation method and application method of low-carbon cement clinker

A technology of low-carbon cement clinker and application method, applied in cement production and other directions, can solve the problems of insufficient cement strength, impossible large-scale production, difficult control of production conditions, etc., and achieve excellent early strength, low resource load, and reduced The effect of coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

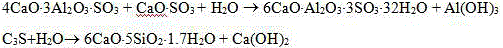

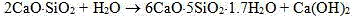

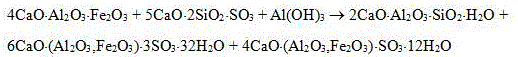

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of low-carbon cement clinker, the preparation method of described low-carbon cement clinker comprises the steps:

[0033] Step 1: Raw material preparation: The raw materials for the preparation of low-carbon cement clinker include silicon-aluminum-containing materials, limestone and gypsum, and the weight-number ratios of each raw material are: 30 parts of silicon-aluminum-containing materials, 60 parts of limestone and 10 parts of gypsum;

[0034] Step 2: Prepare fine material: mix and grind each raw material in the raw material mill after mixing according to the weight parts of each raw material, the raw material fineness is passed through a sieve of 80 microns, and the sieved weight is 9% of the raw material weight, and the fine material is obtained;

[0035] Step 3: calcining: calcining the fine material prepared in step 2 for 20 minutes at high temperature, the calcining temperature is 1280°C;

[0036] Step 4: Cooling: After cooling the...

Embodiment 2

[0047] A kind of preparation method of low-carbon cement clinker, the preparation method of described low-carbon cement clinker comprises the steps:

[0048] Step 1: Raw material preparation: The raw materials for the preparation of low-carbon cement clinker include silicon-aluminum-containing materials, limestone and gypsum, and the weight-number ratios of each raw material are: 30 parts of silicon-aluminum-containing materials, 59 parts of limestone and 11 parts of gypsum;

[0049] Step 2: Prepare fine material: mix and grind each raw material in the raw material mill after mixing according to the weight parts of each raw material, the raw material fineness passes through a sieve of 80 microns, and the residual weight of the sieve is 8% of the raw material weight, and the fine material is obtained;

[0050] Step 3: calcining: calcining the fine material prepared in step 2 at high temperature for 22 minutes, the calcining temperature is 1300°C;

[0051] Step 4: Cooling: After...

Embodiment 3

[0060] A kind of preparation method of low-carbon cement clinker, the preparation method of described low-carbon cement clinker comprises the steps:

[0061] Step 1: Raw material preparation: The raw materials for the preparation of low-carbon cement clinker include silicon-aluminum-containing materials, limestone and gypsum, and the weight-number ratios of each raw material are: 26 parts of silicon-aluminum-containing materials, 62 parts of limestone and 12 parts of gypsum;

[0062] Step 2: Prepare fine material: mix and grind each raw material in the raw material mill after mixing according to the weight parts of each raw material, the raw material fineness passes through a sieve of 80 microns, and the residual weight after sieving is 7% of the raw material weight, so as to obtain the fine material;

[0063] Step 3: calcining: calcining the fine material prepared in step 2 for 25 minutes at high temperature, the calcining temperature is 1250°C;

[0064] Step 4: Cooling: Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com