Regeneration process and regeneration device system of methyl nitrite in process for preparation of ethylene glycol from synthesis gas

A technology for methyl nitrite and synthesis gas, applied in the preparation of nitrite, organic chemistry, etc., can solve the problems of large floor space, low economy, unsatisfactory nitric acid effect, etc., achieve economical and efficient recovery and utilization, reduce nitric acid The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

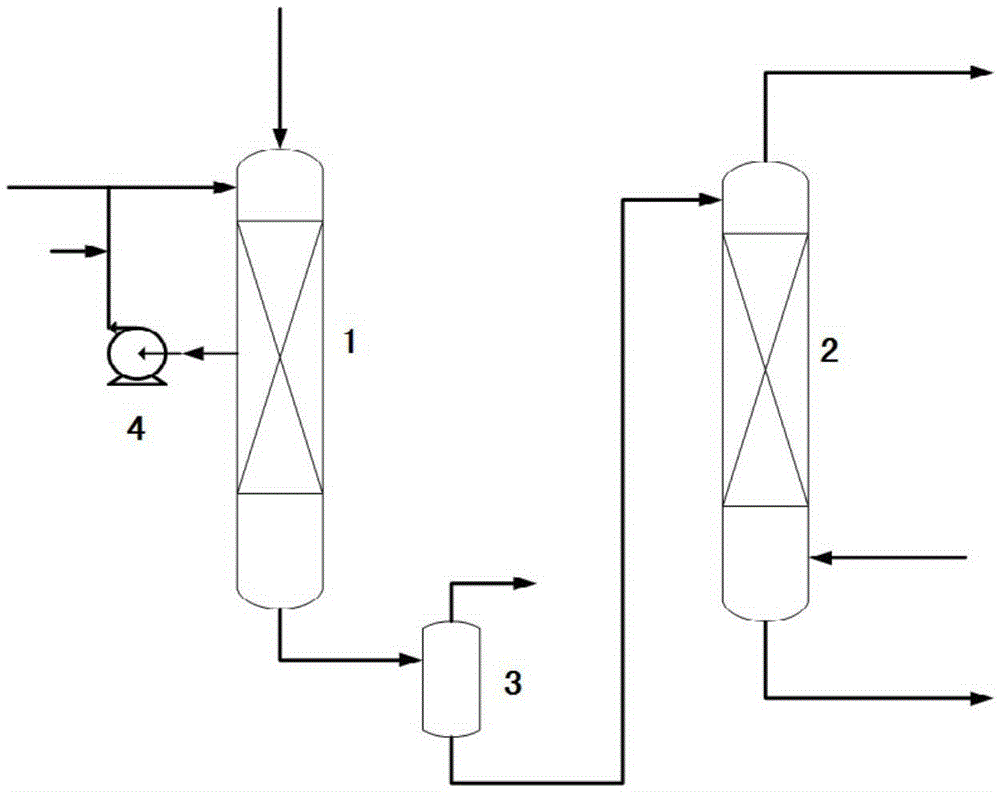

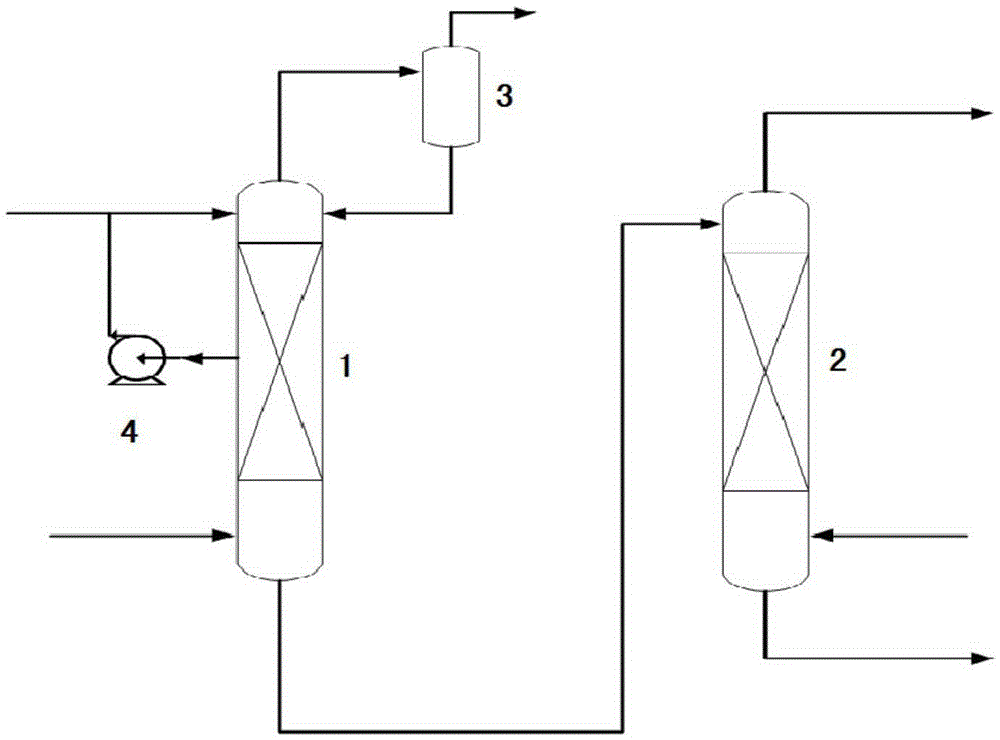

[0054] Such as figure 1 As shown, the regeneration device system of the methyl nitrite regeneration process in the synthesis gas to ethylene glycol process includes a methyl nitrite regeneration tower 1, a methyl nitrite stripping tower 2 and a gas-liquid separator 3.

[0055] The methyl nitrite regeneration tower 1 is provided with a top liquid phase feed port, a top gas phase feed port and a bottom liquid phase discharge port; the methyl nitrite stripping tower is provided with a top liquid phase feed port and a bottom gas phase feed port , The top gas phase outlet and the bottom liquid phase outlet; the gas-liquid separator is equipped with a middle and upper feed inlet, a top gas phase outlet and a bottom liquid phase outlet.

[0056] The middle and upper part of the methyl nitrite regeneration tower 1 is provided with a liquid phase production side line pipeline, and the liquid phase side line pipeline is connected with the top liquid phase feed inlet of the methyl nitrit...

Embodiment 2

[0071] In the regeneration device system and the regeneration process, the bottom gas phase feed port of the methyl nitrite stripping tower is connected to the carbon monoxide gas pipeline through pipelines, and the carbon monoxide gas is passed through the bottom of the methyl nitrite stripping tower for stripping without passing through the nitrous acid The middle and upper side line of the methyl ester regeneration tower is passed into nitric acid, and the others are the same as in Example 1. The methyl nitrite regeneration tower has a diameter of 30 mm and a height of 2600 mm. It is filled with a clover palladium carbon catalyst. The clover palladium carbon catalyst uses activated carbon as a carrier. It is pretreated with hydrochloric acid, and then loaded with nitrate. Press molding to prepare a clover-shaped catalyst with a diameter of Φ1.5*2mm.

[0072] The liquid comprising methanol, nitric acid and water from the methyl nitrite synthesis reactor has a flow rate of 1 ...

Embodiment 3

[0078] The gas phase inlet at the bottom of the methyl nitrite stripping tower in the regeneration unit system and the regeneration process is connected to the inlet gas pipeline of the dimethyl oxalate synthesis reactor through a pipeline, and the inlet gas of the dimethyl oxalate synthesis reactor is obtained from the methyl nitrite vapor The bottom of the stripping tower is passed into and stripped, and nitric acid is not passed through the middle and upper side line of the methyl nitrite regeneration tower, and others are the same as in Example 1. The methyl nitrite regeneration tower has a diameter of 30mm and a height of 2600mm. It is filled with a clover palladium carbon catalyst. The clover palladium carbon catalyst uses activated carbon as a carrier. Press molding to prepare a clover-shaped catalyst with a diameter of Φ1.5*2mm.

[0079] The liquid containing methanol and nitric acid from the methyl nitrite synthesis reactor has a flow rate of 1 kg / h, wherein the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com