Method for synthesizing alkyl nitrite

A technology of alkyl nitrite and alkyl alcohol, which is applied in the preparation of nitrite, organic chemistry, etc., can solve the problems of high investment cost, high operating cost, large reactor diameter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

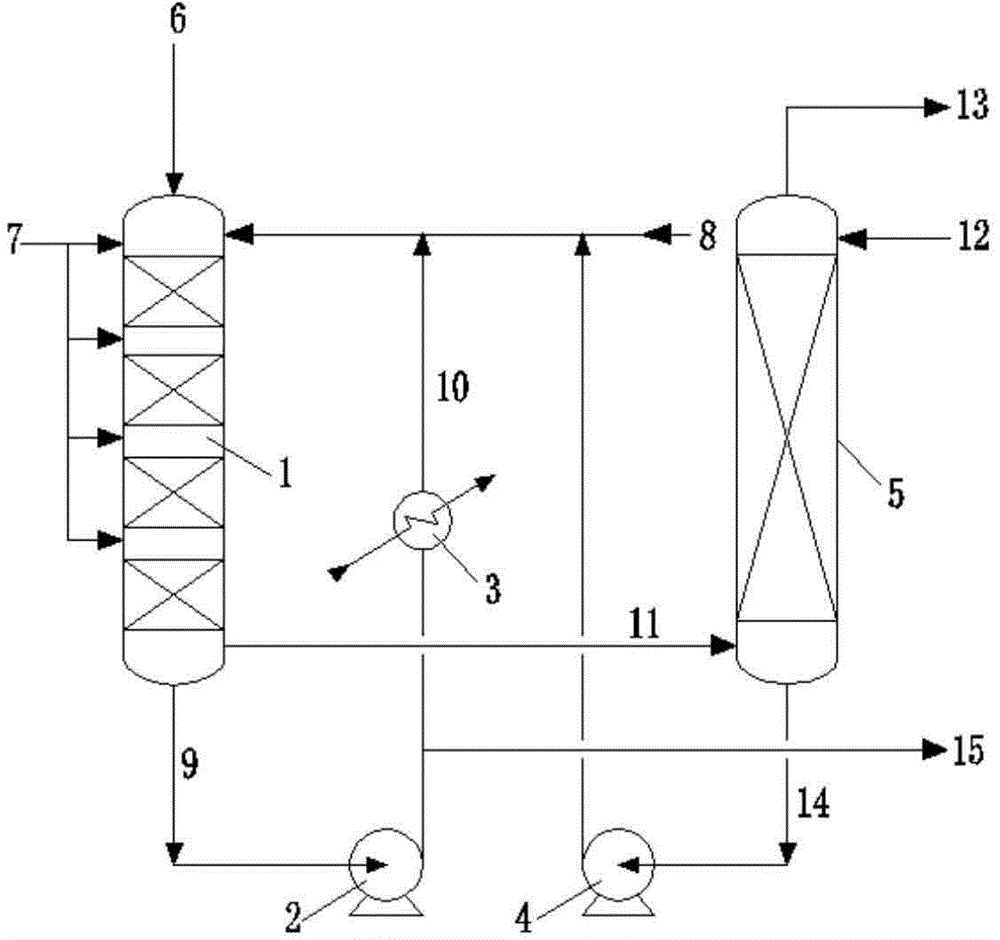

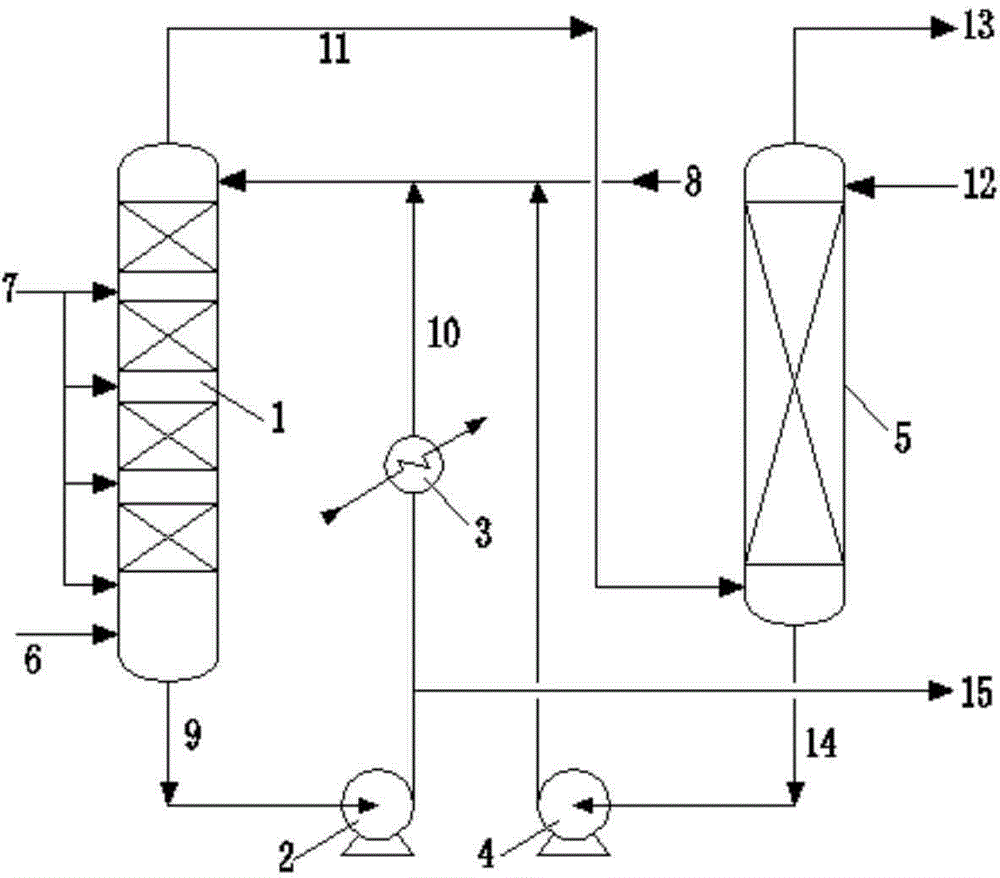

Method used

Image

Examples

Embodiment 1

[0042] The methyl nitrite production process of the present embodiment is used for the scale of producing 1000 tons of dimethyl oxalate per year.

[0043] Containing NO circulating gas flow rate 500Nm 3 / h, molar composition NO=15%, CO=8%, methyl nitrite=5%, methyl alcohol=6%, N 2 = 66%.

[0044] Oxygen flow rate 12.9Nm 3 / h, the purity is 99.8% by weight, the rest is N 2 .

[0045] The esterification reactor has a diameter of 0.25m and a height of 8.2m. It is in the form of a packed tower. There are four sections of packing. The packing heights are 1 / 1 / 1 / 2m respectively. The pressure at the top of the reactor is controlled at 0.25MPag.

[0046] The purity of fresh methanol is 99.9%, the flow rate is 0.13m 3 / h, temperature 20°C. Circulating methanol 3.9m 3 / h, the circulating methanol is cooled by a heat exchanger, and the temperature of the tower tank of the esterification reactor is controlled at 45°C.

[0047] The washing tower has a diameter of 0.25m and a height ...

Embodiment 2

[0051] The methyl nitrite production process of the present embodiment is used for the scale of producing 10,000 tons of dimethyl oxalate per year.

[0052] 4960Nm circulating air flow containing NO 3 / h, molar composition NO=15%, CO=8%, methyl nitrite=5%, methyl alcohol=6%, N 2 = 66%.

[0053] Oxygen flow rate 126Nm 3 / h, the purity is 99.8%, the rest is N 2 , Feeding in four sections.

[0054] The esterification reactor has a diameter of 0.9m and a height of 14.5m. It is in the form of a packed tower. There are four sections of packing. The packing heights are 2 / 2 / 2 / 3m respectively. The pressure at the top of the reactor is controlled at 0.25MPag.

[0055] The purity of fresh methanol is 99.9%, the flow rate is 1.3m 3 / h, temperature 20°C. Circulating methanol 38.7m 3 / h, the circulating methanol is cooled by a heat exchanger, and the temperature of the tower tank of the esterification reactor is controlled at 45°C.

[0056] The washing tower has a diameter of 0.9m a...

Embodiment 3

[0060] The methyl nitrite production process of the present embodiment is used for the scale of producing 100,000 tons of dimethyl oxalate per year.

[0061] 49550Nm circulating air flow containing NO 3 / h, molar composition NO=15%, CO=8%, methyl nitrite=5%, methyl alcohol=6%, N 2 = 66%.

[0062] Oxygen flow rate 1246Nm 3 / h, the purity is 99.8%, the rest is N 2 , feeding in four stages,

[0063] The esterification reactor has a diameter of 2.6m and a height of 20.5m. It is in the form of a packed tower. There are four sections of packing. The packing heights are 3 / 3 / 3 / 4m respectively. The pressure at the top of the reactor is controlled at 0.25MPag.

[0064] The purity of fresh methanol is 99.9%, and the flow rate is 12.9m 3 / h, temperature 20°C. Circulating methanol 387.1m 3 / h, the circulating methanol is cooled by a heat exchanger, and the temperature of the tower tank of the esterification reactor is controlled at 45°C.

[0065] The washing tower has a diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com